𝗔𝘂𝘁𝗼 𝗦𝗽𝗮𝗿𝗲 𝗣𝗮𝗿𝘁𝘀 𝗟𝗼𝗴𝗶𝘀𝘁𝗶𝗰𝘀

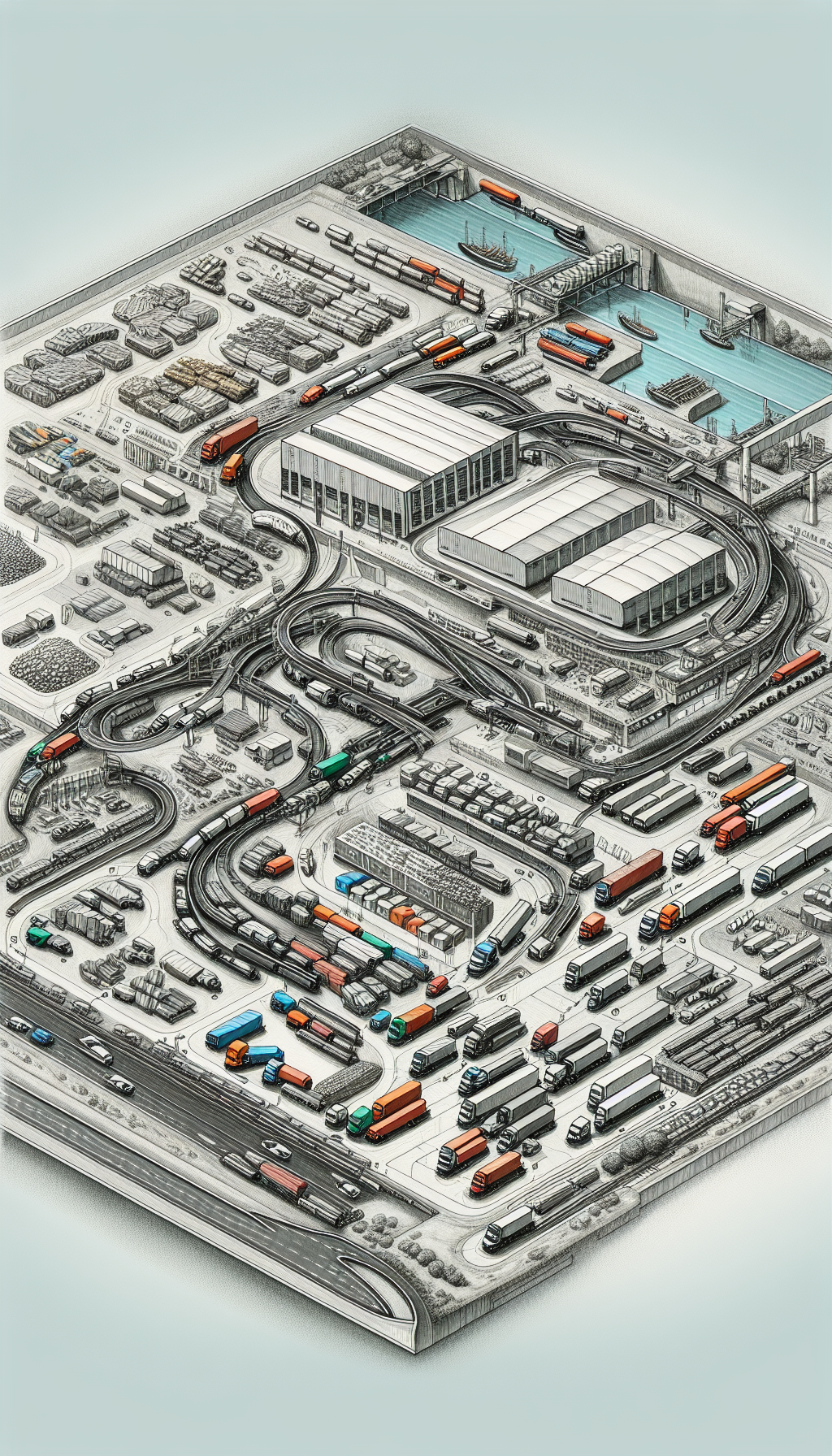

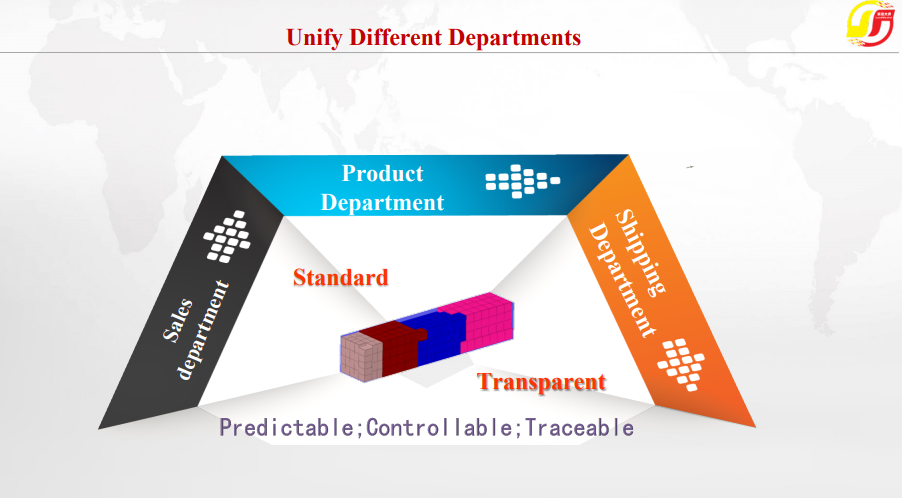

In the modern automotive industry, auto spare parts logistics is a crucial link to ensure smooth vehicle maintenance and repair. However, this process involves multiple complex steps, from supplier procurement to final delivery, each with its unique challenges. The complexity of inventory management, the high requirements for flexible order processing, the diversity of parts packaging, and the efficiency of transportation and distribution are all key factors affecting the efficiency of auto parts logistics.

𝗦𝗶𝗰𝗵𝘂𝗮𝗻 𝗙𝗔𝗪 𝗧𝗼𝘆𝗼𝘁𝗮

Sichuan FAW Toyota Motor Co., Ltd. (SFTM), established in 2000, is one of the joint ventures of FAW Toyota Motor Company in China, mainly producing Toyota brand sedans and SUVs. Its spare parts logistics is an important part of the company’s supply chain management, responsible for transporting auto parts from suppliers to production lines and repair sites.

𝗕𝗲𝗳𝗼𝗿𝗲 𝘂𝘀𝗶𝗻𝗴 𝗟𝗼𝗮𝗱𝗠𝗮𝘀𝘁𝗲𝗿 𝗰𝗼𝗻𝘁𝗮𝗶𝗻𝗲𝗿 𝗹𝗼𝗮𝗱𝗶𝗻𝗴 𝘀𝗼𝗳𝘁𝘄𝗮𝗿𝗲

In 2013, Sichuan FAW Toyota purchased and began using the LoadMaster 3d load calculator to solve the loading challenges of after-sales spare parts logistics at its logistics centers in Chengdu and Tianjin. They have been collaborating for over 11 years. Their daily orders can be divided into two types: 1) Stable orders; 2)Temporary additional orders.

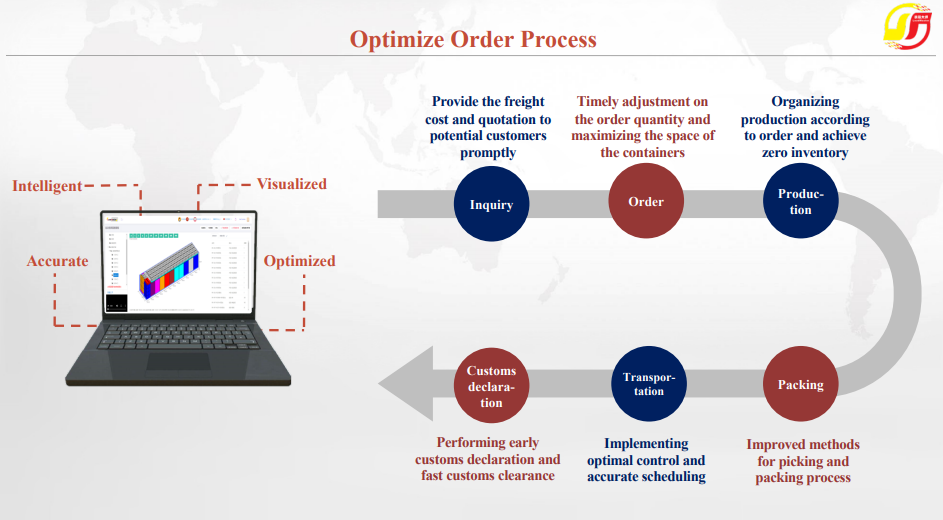

The business process for these two types of orders in the logistics center is as follows:

1)Manually give an approximate design of a shipping plan based on stable orders. (A rough estimation of how the cargo will be loaded into trucks based on the volume of goods.) Then roughly estimate the model and number of vehicles required for transportation. In the end, draw the detailed packing plan.

2)If there are temporary additional orders, the 3d loading plan needs to be re-estimated manually, the model and number of vehicles required for transportation re-estimated, and the detailed loading plan redrawn.

Under such a process, the disadvantages are obvious:

- The loading plan drawn based on the estimated cargo volume differs from the actual loading situation since it’s just a rough approximate one.

- When there are urgent additional orders, the loading plan cannot be adjusted flexibly and immediately by manpower.

- Manual drawing is time-consuming, labor-intensive, error-prone, and costly in terms of man-hours.

𝗔𝗳𝘁𝗲𝗿 𝘂𝘀𝗶𝗻𝗴 𝗟𝗼𝗮𝗱𝗠𝗮𝘀𝘁𝗲𝗿 𝗰𝗼𝗻𝘁𝗮𝗶𝗻𝗲𝗿 𝗹𝗼𝗮𝗱𝗶𝗻𝗴 𝘀𝗼𝗳𝘁𝘄𝗮𝗿𝗲

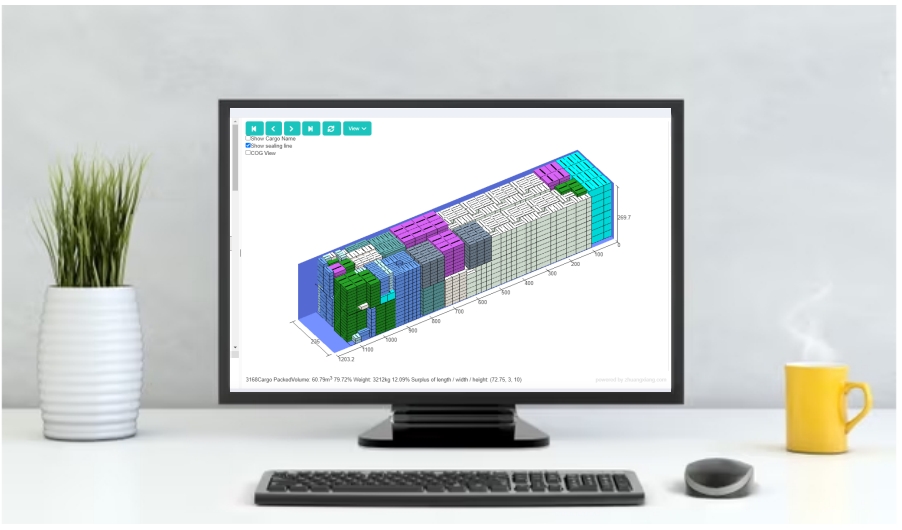

In this situation, they turned to the LoadMaster software, hoping it could help solve their current business challenges. After testing with real data and fully understanding LoadMaster’s powerful functionalities, they found that:

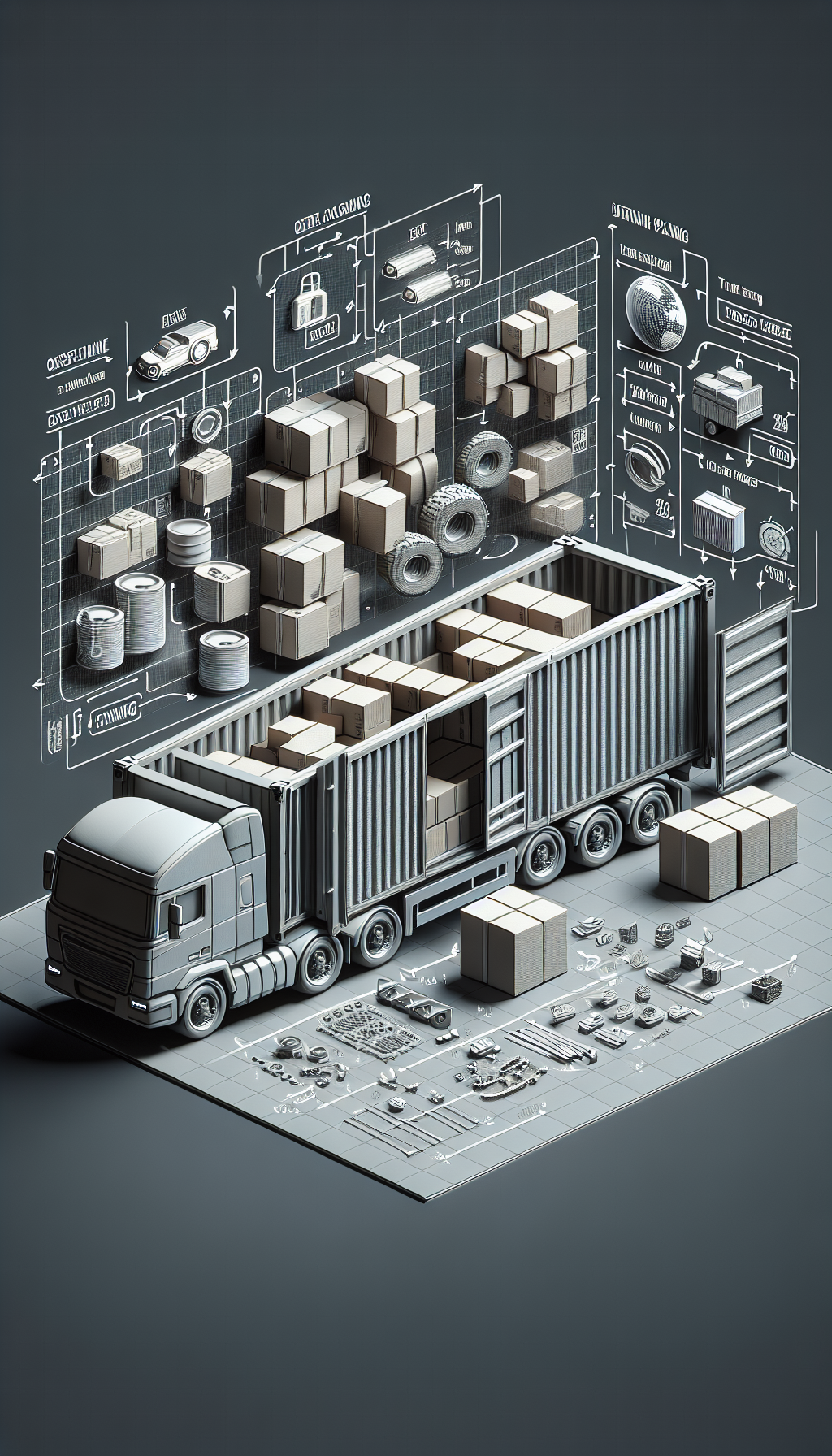

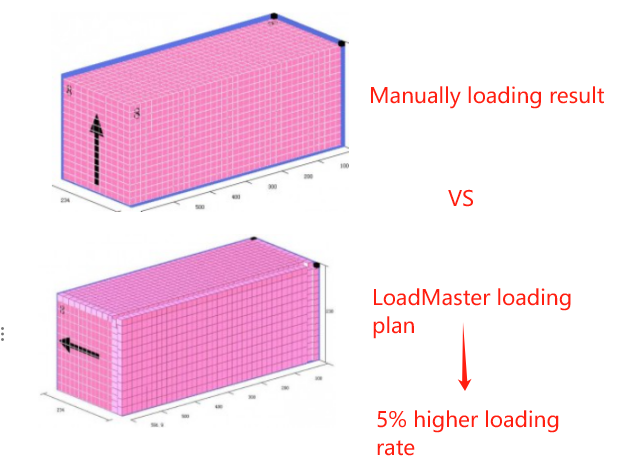

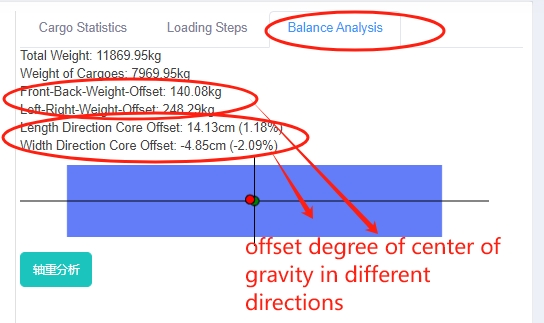

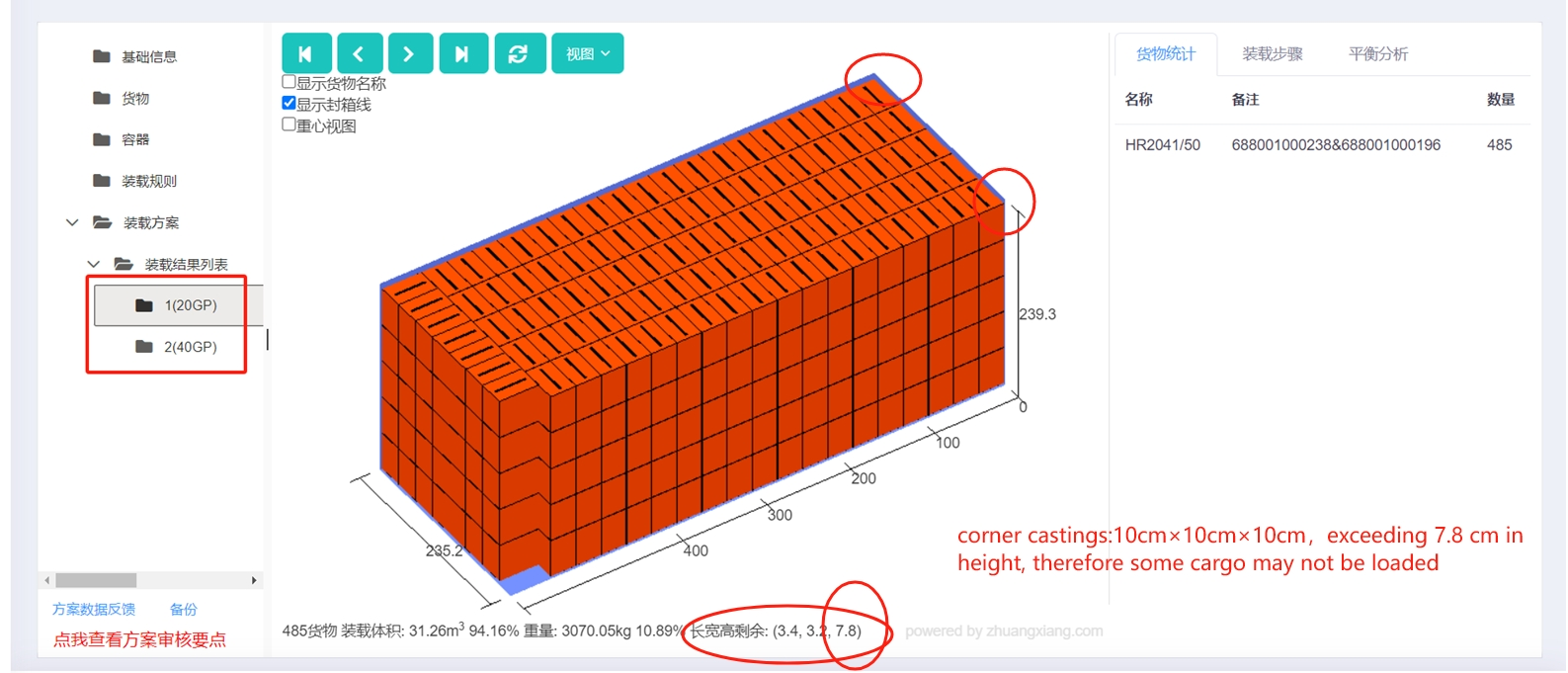

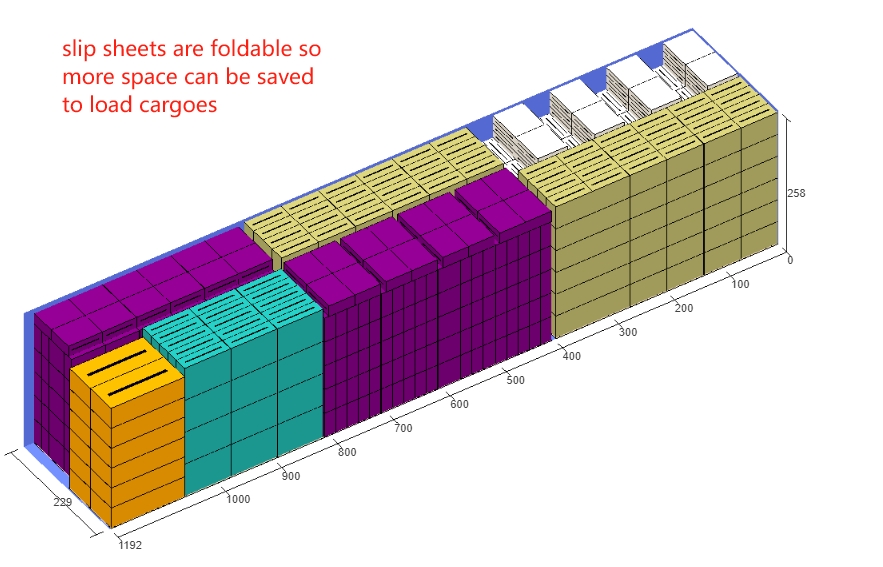

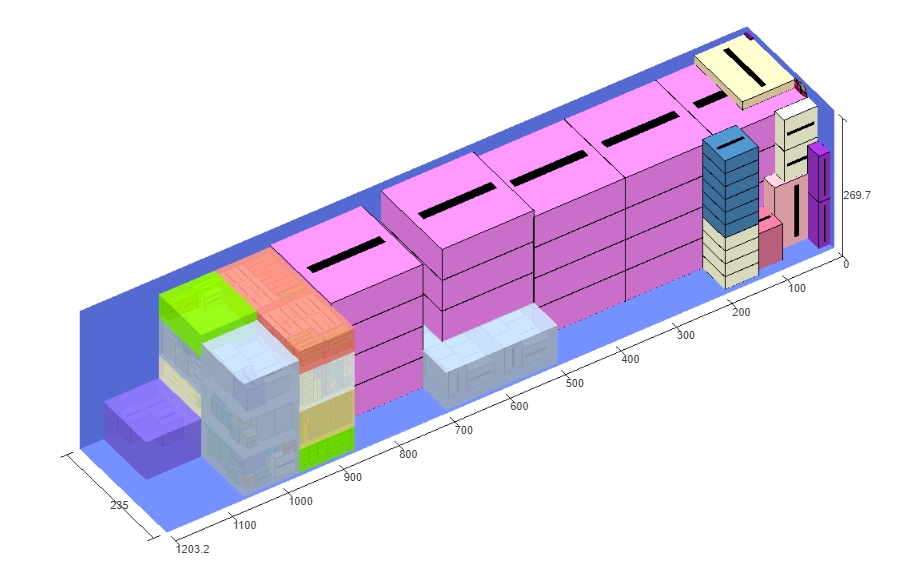

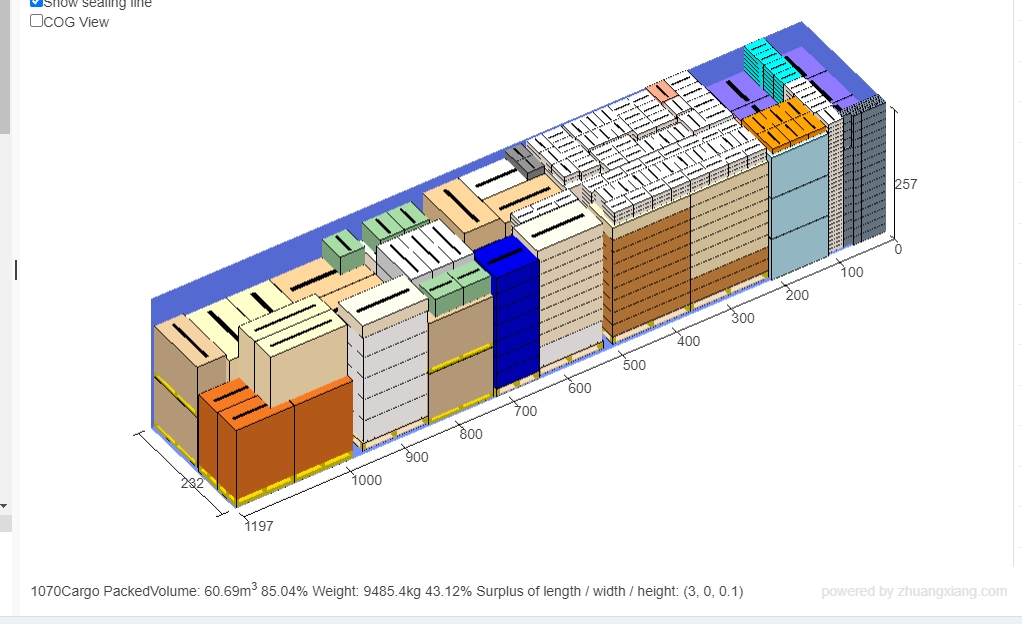

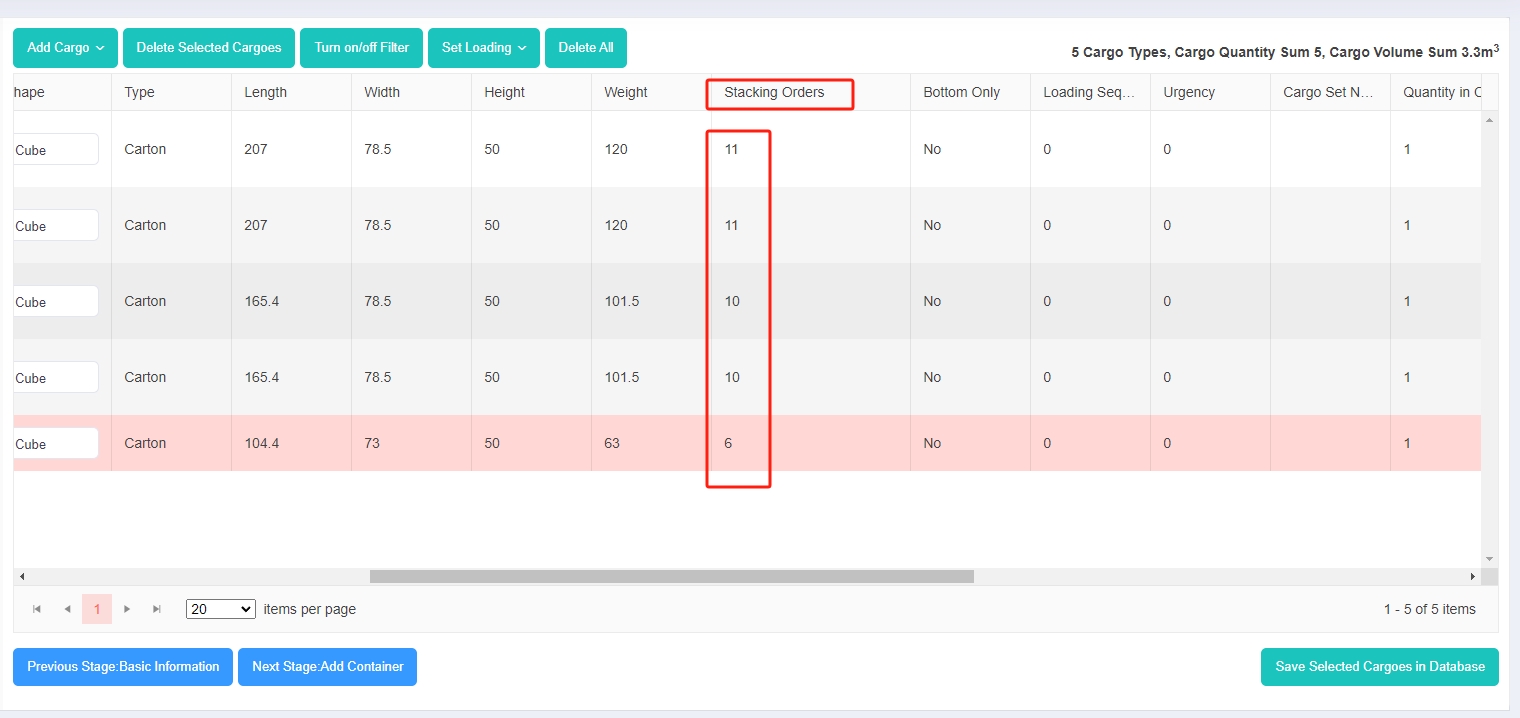

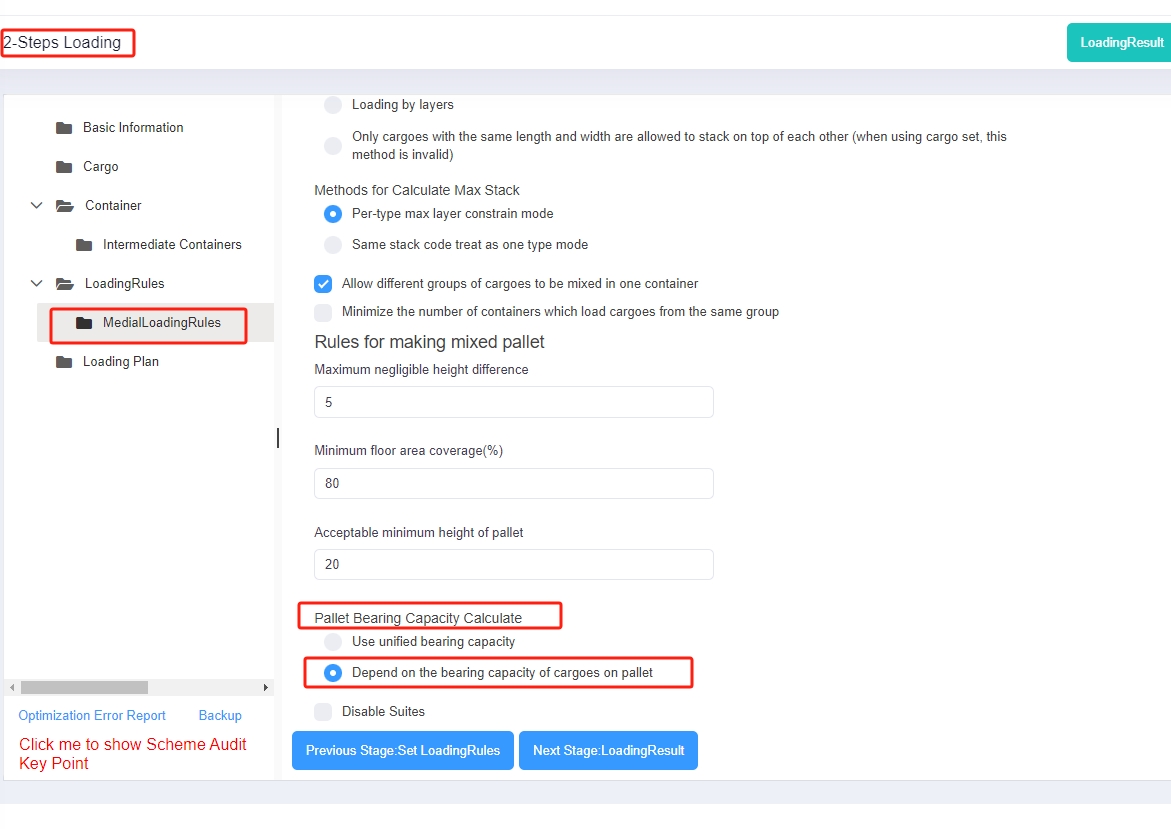

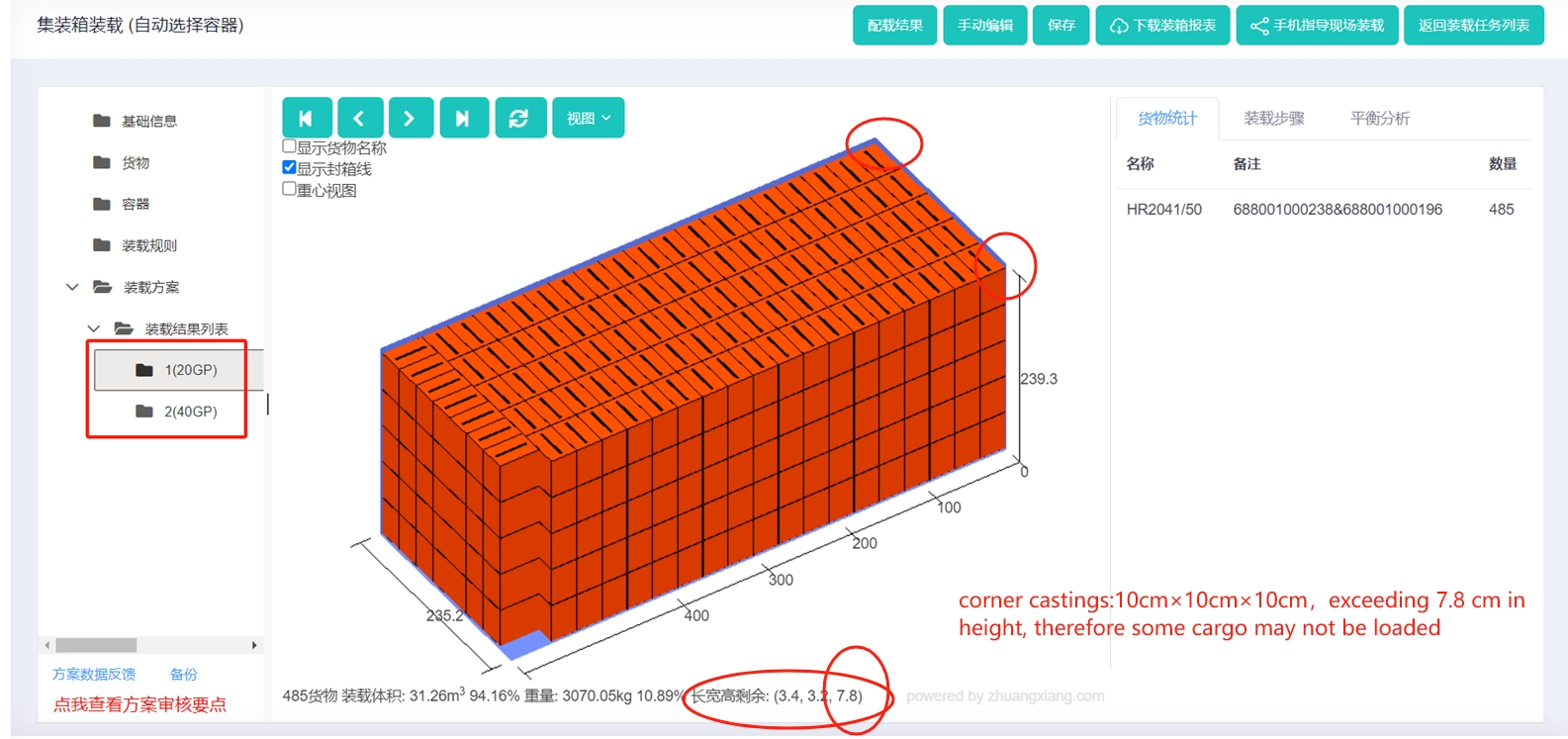

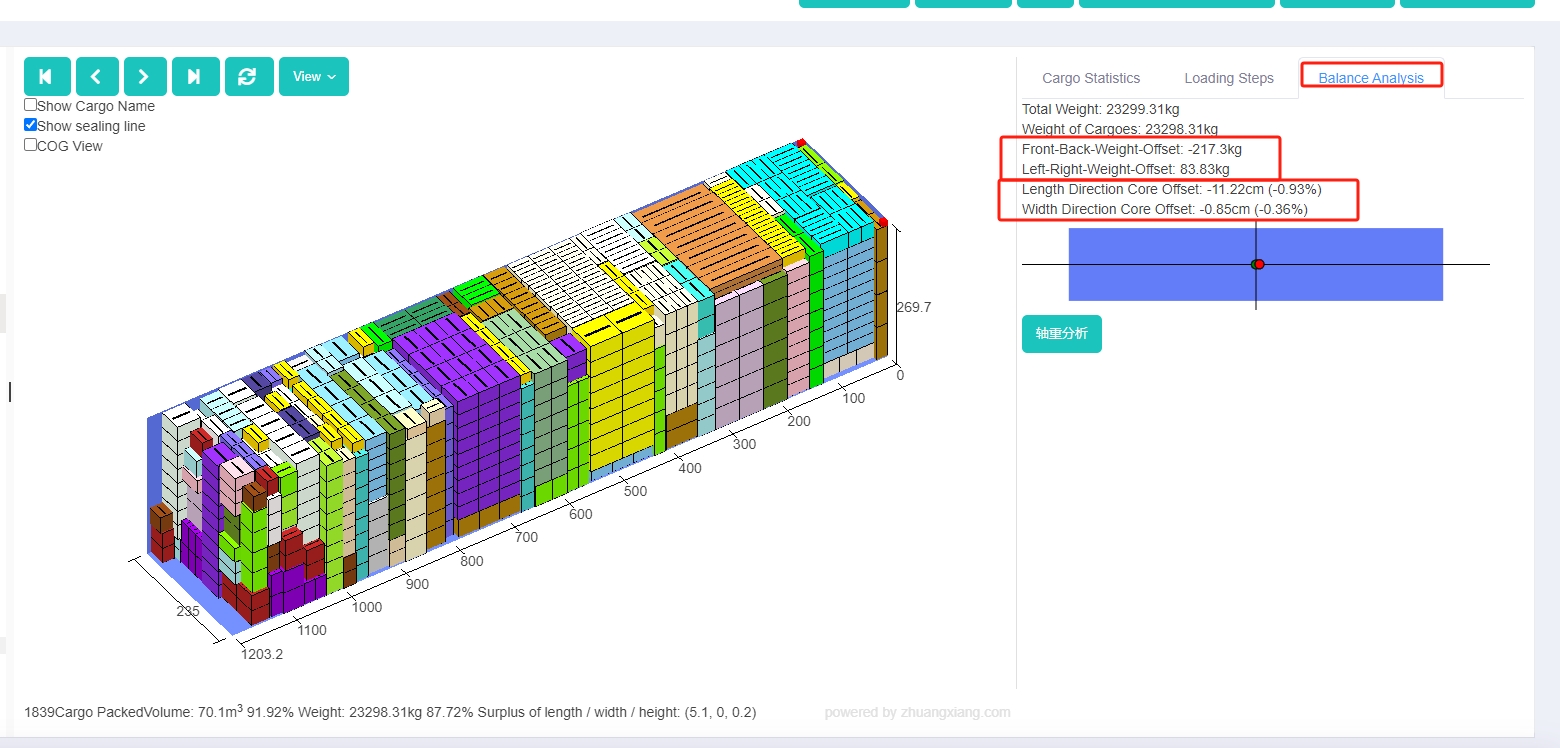

- The LoadMaster software can quickly achieve a batch of cargo data imported and produce accurate loading plans quickly, which helps improve the loading rate of vehicles while meeting loading requirements.

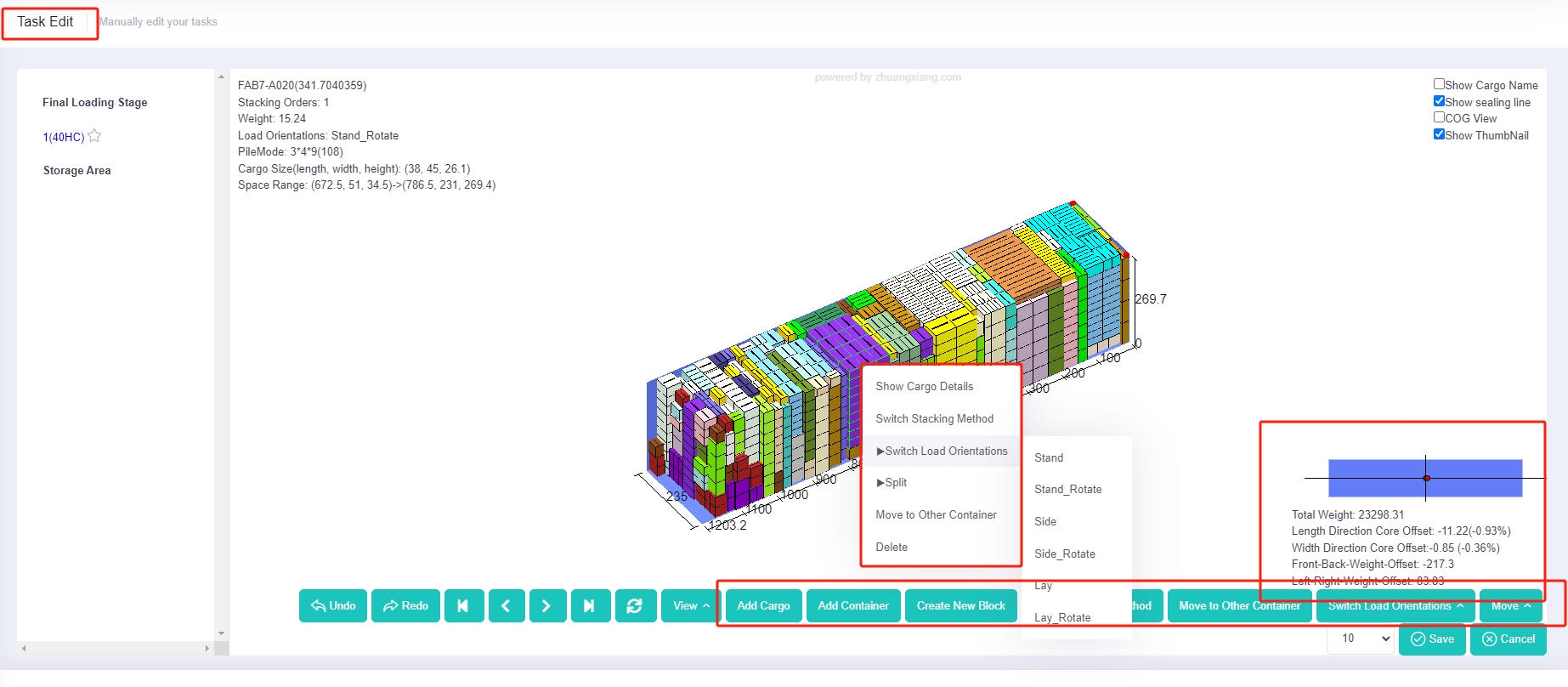

- When the cargo quantity in the order changes temporarily, the loading plan can be edited and modified flexibly to quickly get a new loading plan.

- The software provides not only 3D loading plans but also detailed loading steps to guide on-site workers in loading operations.

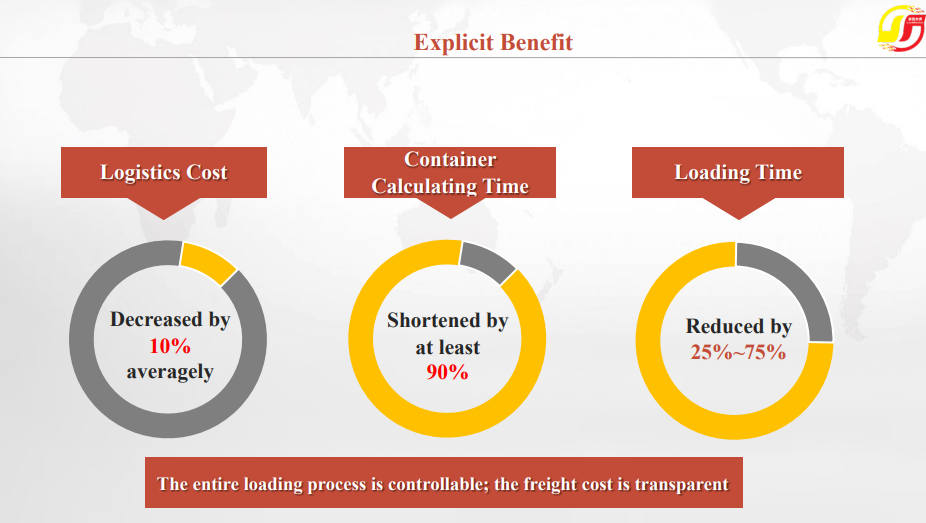

- The entire process becomes faster and more efficient, significantly shortening the cycle of calculation, loading, and transportation.

Delighted by how LoadMaster container loading calculator solved their difficult loading problems and brought such significant improvements, Sichuan FAW Toyota established a long-term partnership with LoadMaster.

In the future, LoadMaster container loading software will continue to empower Sichuan FAW Toyota, helping the company reduce costs and increase efficiency, and achieve more benefits from detailed operations!

(

(

(

( (

(