After knowing how to set parameters in the LoadMaster truck load planning software to reduce cargo damage in the same kind of cargoes, let’s see how to reduce that in different kinds of cargoes.

When a set of cargoes have following loading requirements such as heavy ones cannot press light ones or big ones cannot press small ones, we can meet these requirements by setting “Stacking Orders”, which indicates the loading capacity of each cargo. Cargoes with bigger “Stacking Orders” number have bigger loading capacity and should be placed under those with smaller “Stacking Orders” number.

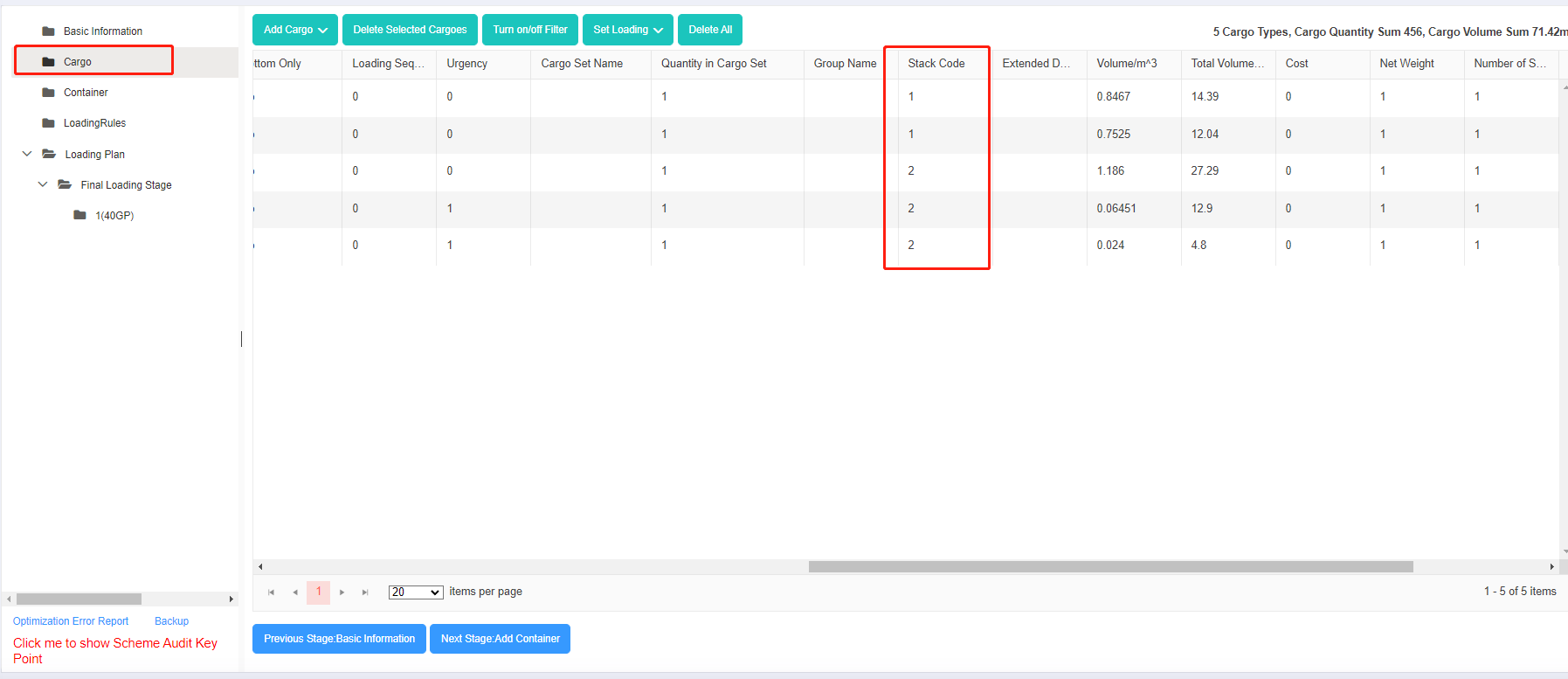

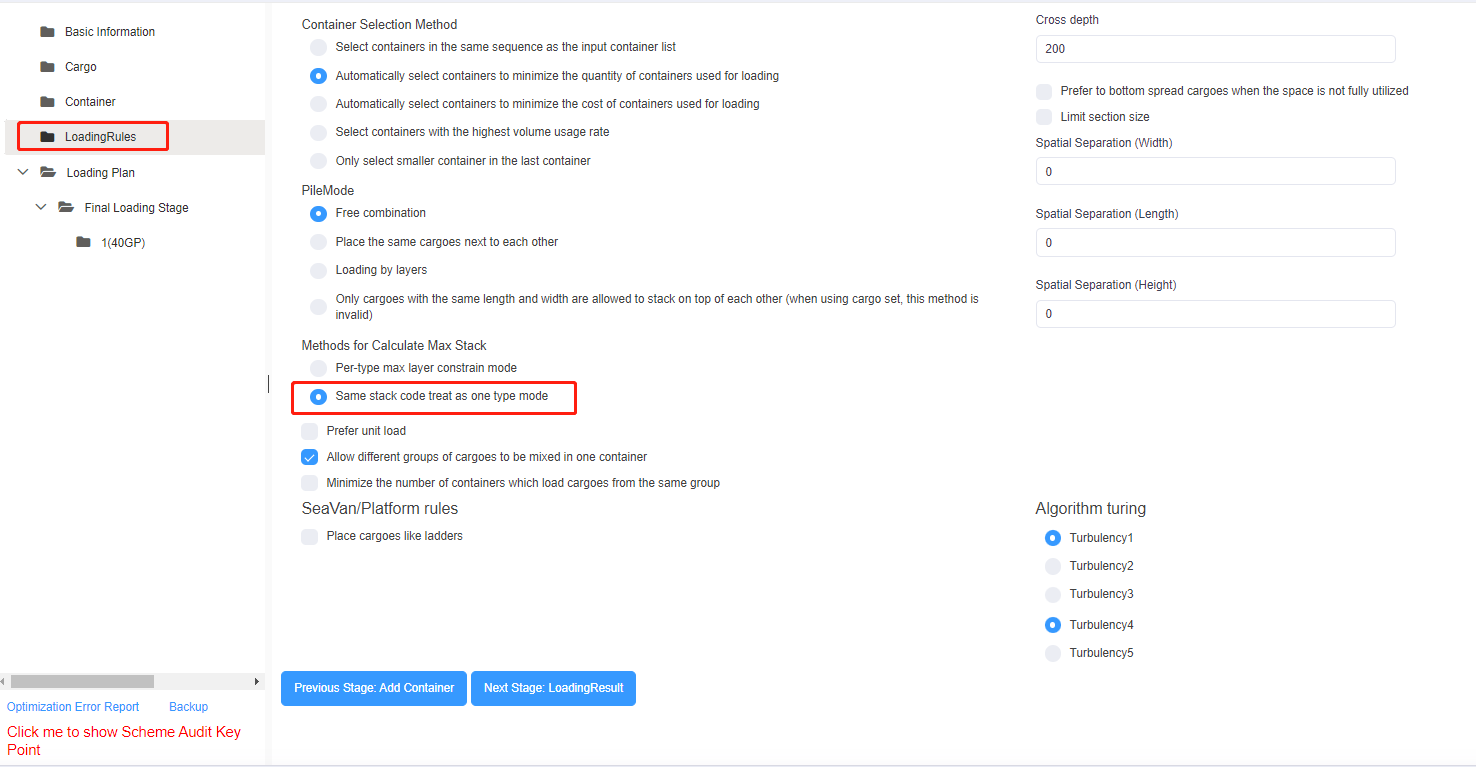

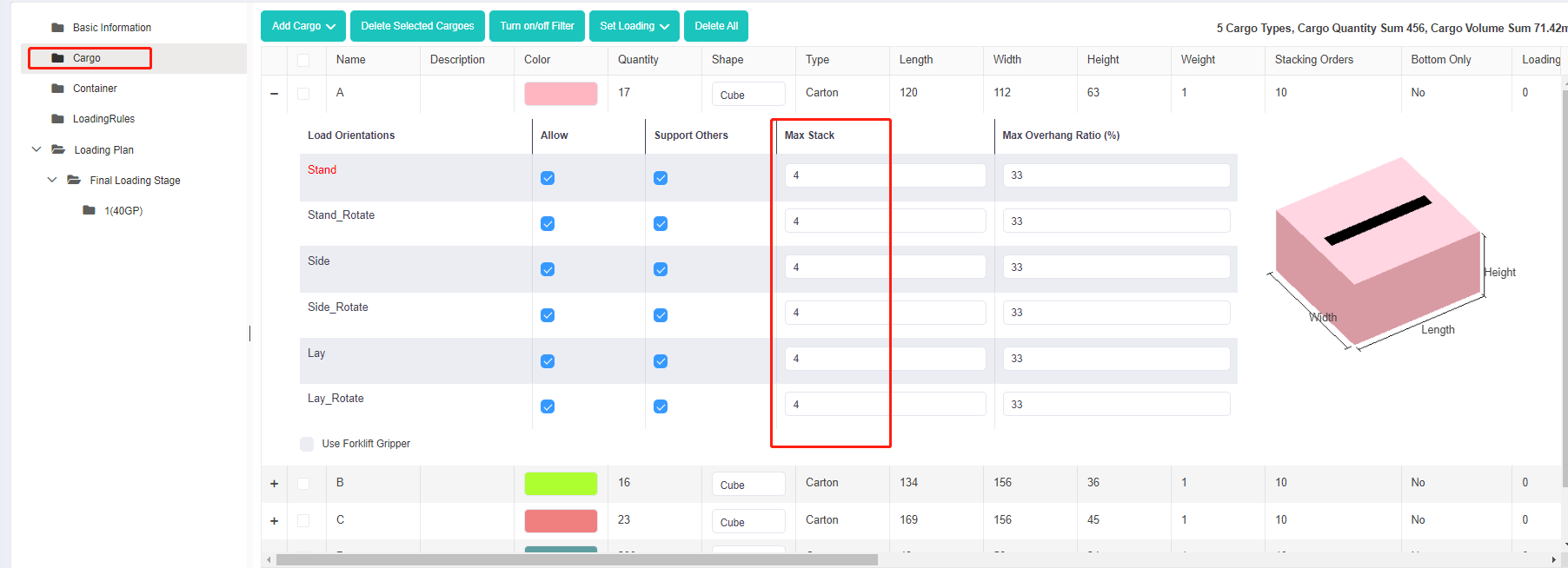

In most cases when different kinds of cargoes are allowed to be loaded in one container, they can be stacked by each other for the sake of a high container utilization rate without which clients who receive cargoes will complain and show dissatisfaction. Under such circumstance, we can set the same “Stacking Code” for cargoes that can be stacked by each other, in which way these cargoes will be regarded as the same kind to stack. Also we need to set the loading rule “Same stack code treat as one type mode”. However, even these cargoes are allowed to stack as the same kind, they should have a maximum stacking layer to try to avoid the cargo damage because each cargo have the biggest loading capacity which, if exceeded, will be broken and then lead to cargo damage. Therefore, we need to set the “Max Stack” for each of these cargoes.

This is Stack Code interface.

This is Stack Code interface.

This is “Same Stack code treat as one type mode” rule.

This is “Same Stack code treat as one type mode” rule.

This is the same Max Stack.

This is the same Max Stack.

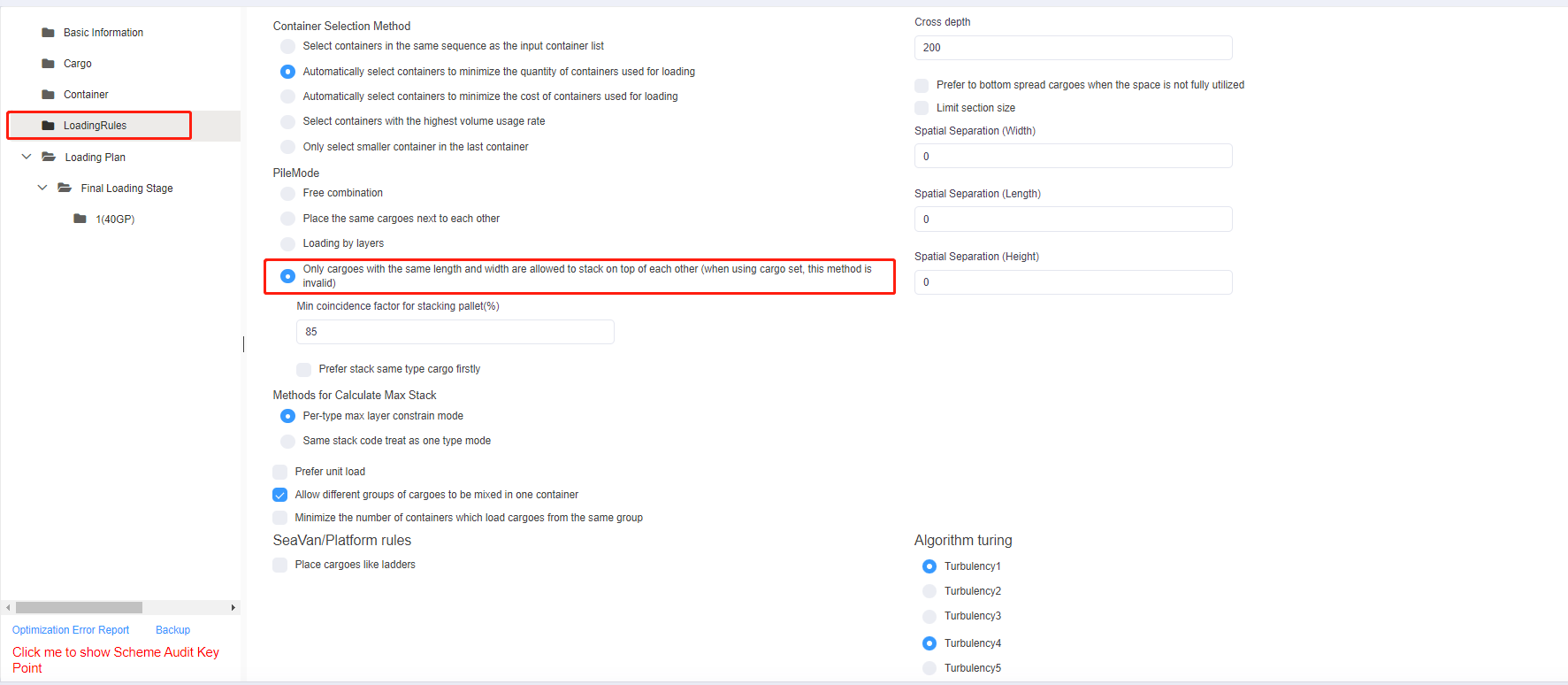

As for cargoes that are high-value such as cargoes in the auto parts industry, it is often required to only stack those with the same or similar lengths and widths and to realize high-to-low loading from front to end in containers, aiming to reduce cargo damage as much as possible. Therefore, you can check “Only cargoes with the same length and width are allowed to stack on top of each other (when using cargo set, this method is invalid)” in the “Loading Rules” interface.

This is “Only cargoes with the same length and width are allowed to stack on top of each other” rule.

This is “Only cargoes with the same length and width are allowed to stack on top of each other” rule.

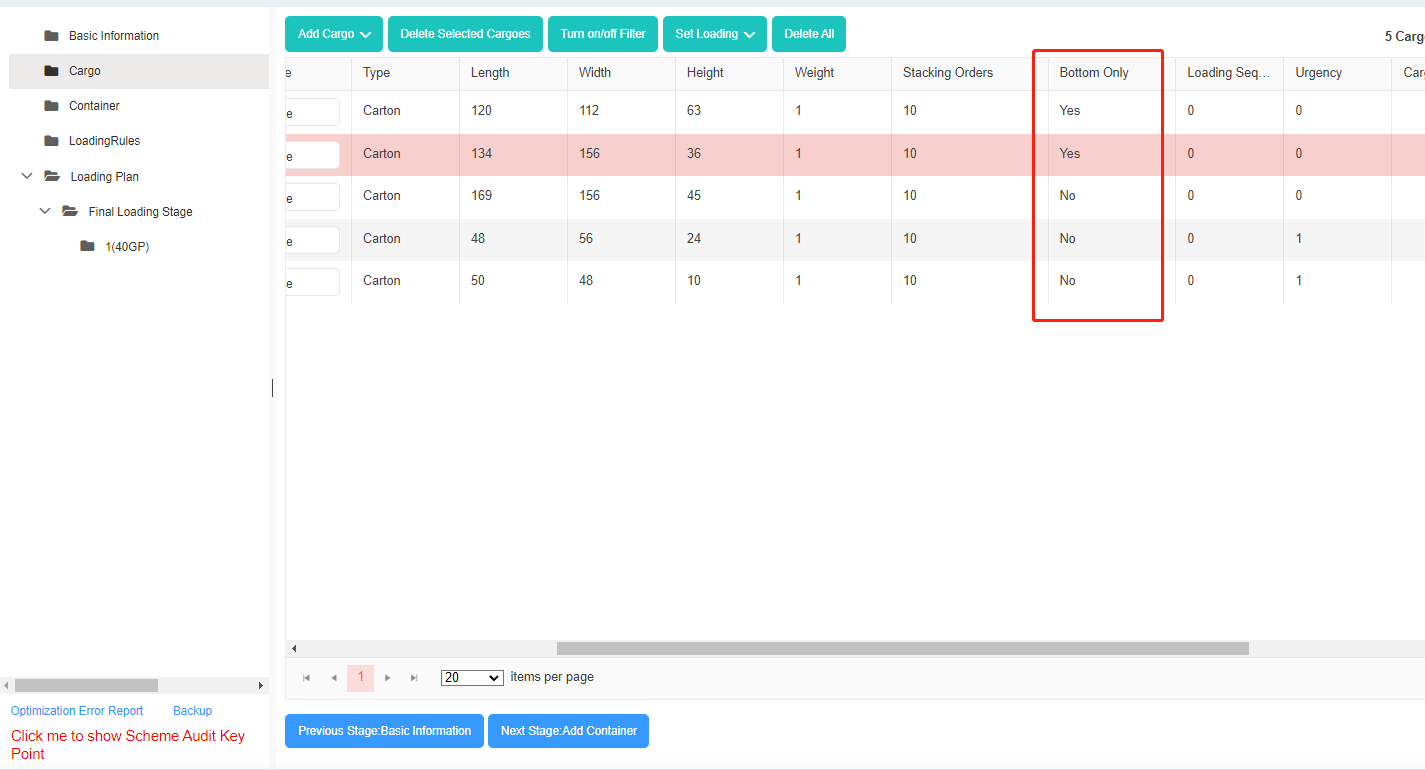

And if cargoes are heavy, it it recommended to place them at the bottom of containers. Therefore you can check “Bottom Only” for these heavy cargoes in Cargo interface.

This is “Bottom Only” interface.

This is “Bottom Only” interface.

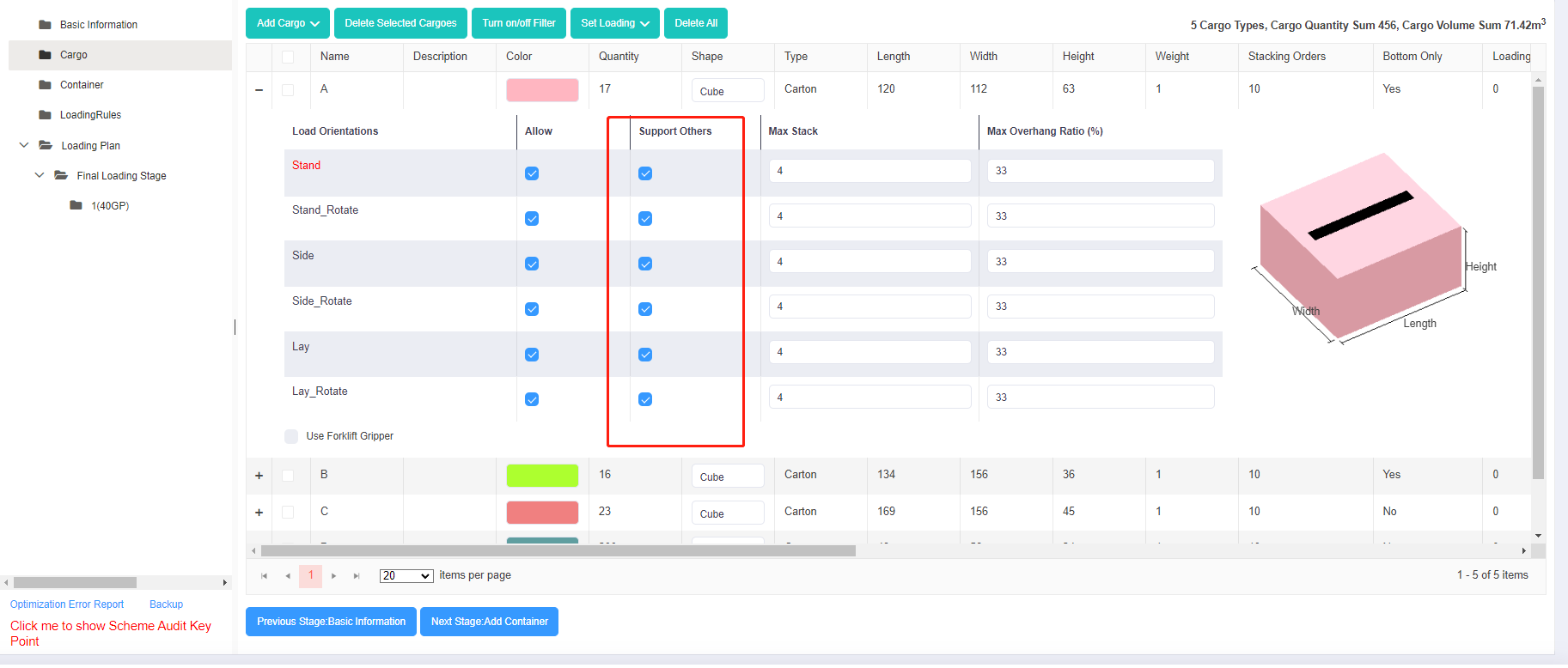

Cargoes with different methods of placement have different loading capacities. Under this prerequisite, some cargoes can only stack by themselves while others can be stacked by other kinds of cargoes. And you can decide if they can be stacked under other cargoes by setting the parameter “Support Others” in Cargo interface.

This is “Support Others” interface.

This is “Support Others” interface.

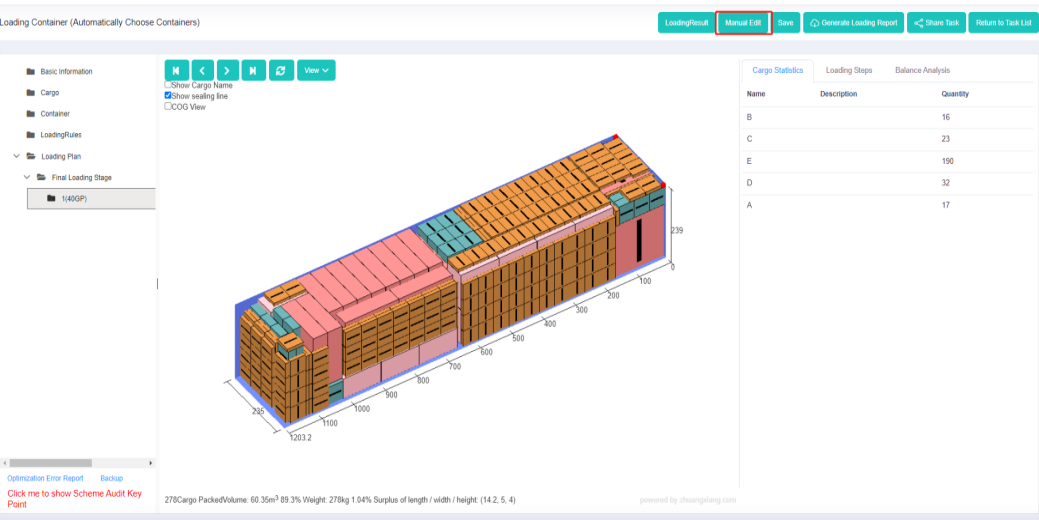

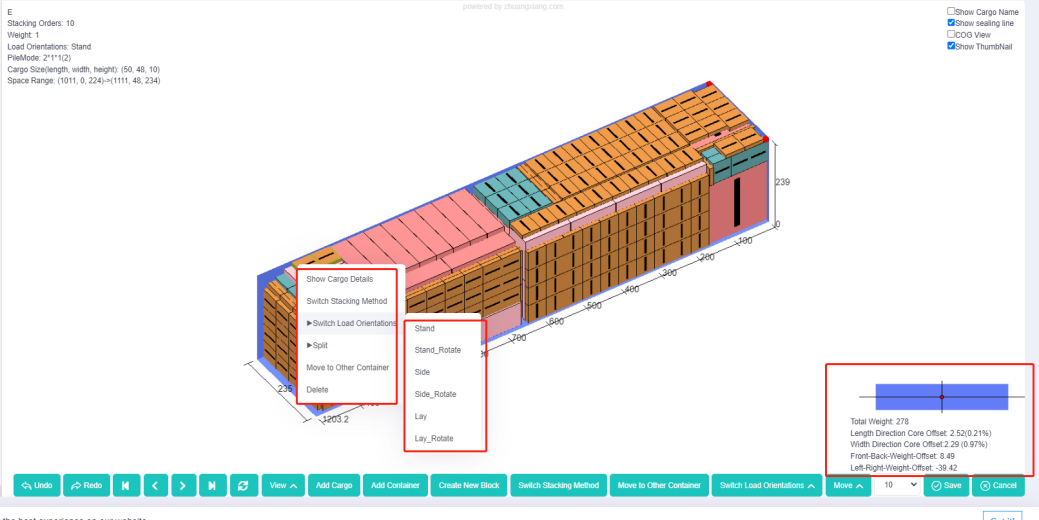

After setting all parameters and loading rules, an optimal load plan will be offered by LoadMaster load planning calculator. However, sometimes, the balance of containers cannot meet the requirements for railway and shipping. Don’t worry, LoadMaster truck load planning software can help you adjust the balance of containers by switching the methods of placement and location of cargoes in containers through the “Manual Edit”.

This is manual edit button.

This is manual edit button.

This is manual edit operation interface.

This is manual edit operation interface.

In short, with the help of LoadMaster truck load planning software, cargo damage can be avoided to the largest extent.