In case of the palletized cargoes being loaded into containers, sometimes it is required to calculate how to stack boxes on a pallet in an optimal way before container loading calculation. Therefore the calculation becomes more complicated, far beyond human mind. Under such circumstances, LoadMaster load planning optimization software indicates its advantages! Let’s check it out!

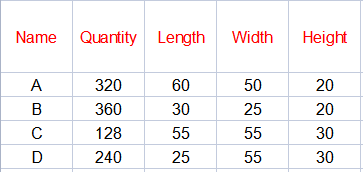

For example, there is an order of cargoes needed to to be loaded into containers. Cargo information is as follows.

This is cargo dimension.

This is cargo dimension.

Loading requirements:

- Cargoes cannot be placed with their length vertical to the container ground.

- Select the most suitable type of pallets and calculate how to optimally load cargoes on these pallets. Then select the most suitable type of containers and calculate container loading.

- The height of the pallet is limited to 1.1 meters (including the height of the pallet itself).

Next let’s see how to operate in LoadMaster step by step.

First, determine the task type. Click “Two-steps Loading”.

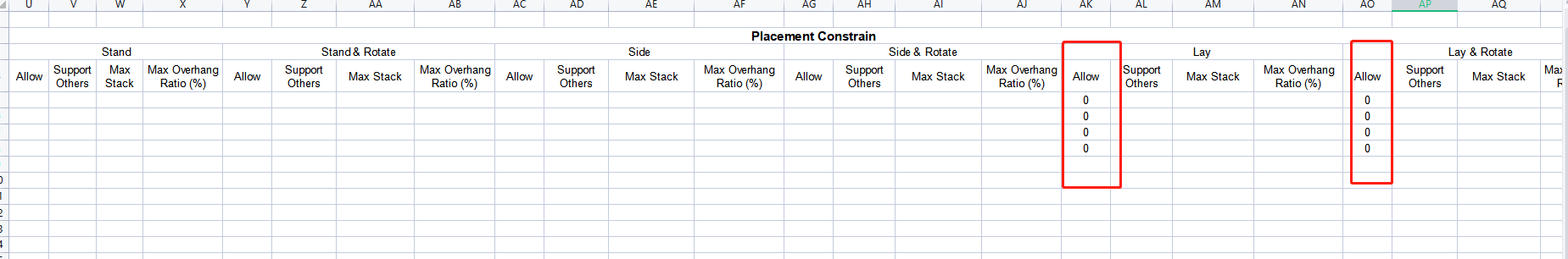

Then add cargoes through Excel template. Since cargoes are required not to be placed with their length vertical to the container ground which means they can not Lay, Lay&Rotate. Fill in “0” in the columns of these two stacking codes.

This is placement orientation parameter set.

This is placement orientation parameter set.

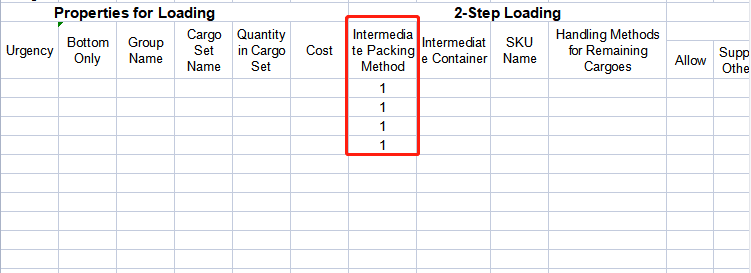

Since cargoes need to be palletized and the pallet type is uncertain, fill in”1” in the column of “Inteermidiate Packing Method”. “1” means pallet type is uncertain so that LoadMaster load planning optimization software can intelligently select the most suitable pallet type.

This is intermediate packing method parameter set.

This is intermediate packing method parameter set.

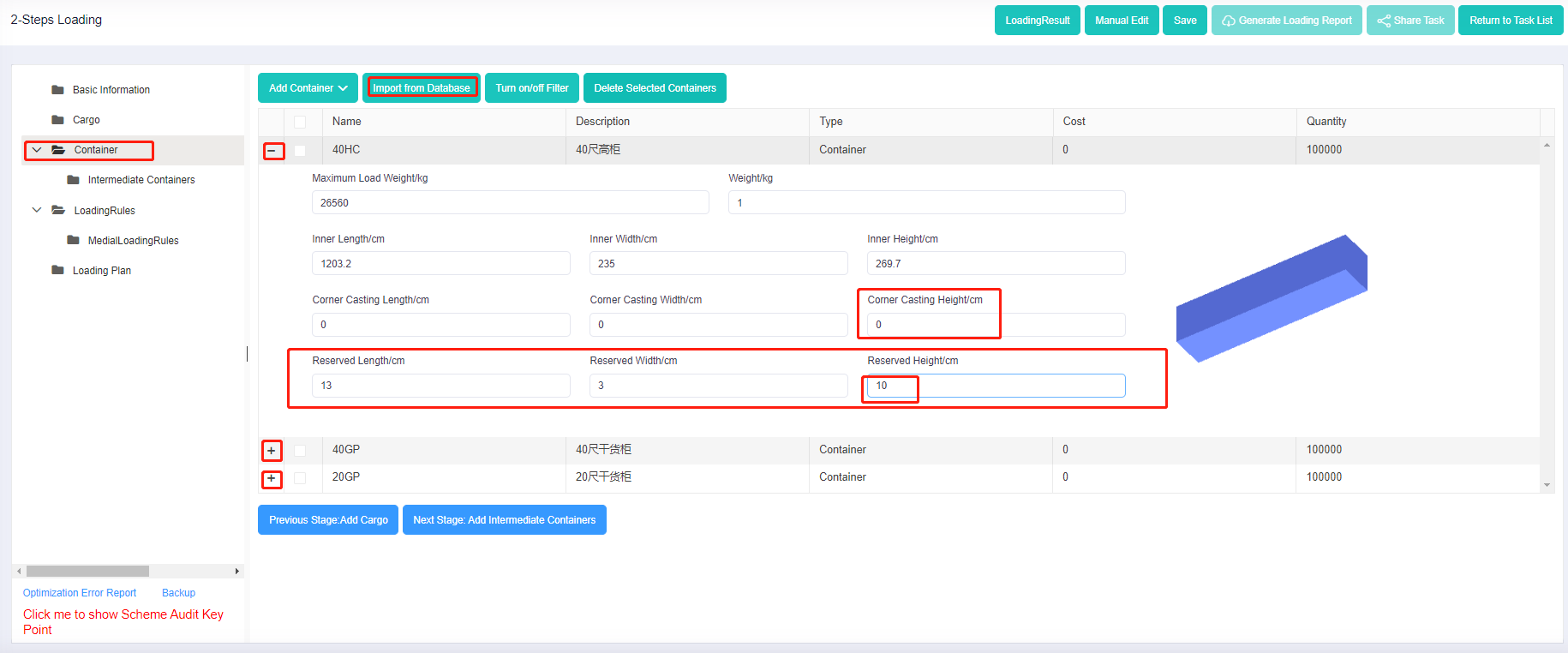

Then add containers into the container loading calculator. Since container type is also uncertain, it is recommended to add the frequently used containers from the container database. In this way, LoadMaster can also intelligently select the most suitable container.

It should be noted that the cargoes are loaded into containers with pallet package, so forklift is gonna be used. For the sake of convenience of forklift operation, set the “Reserved Height” as 10cm and then the “Corner Casting Height” doesn’t need to be set.

Corner castings and reserved size set.

Corner castings and reserved size set.

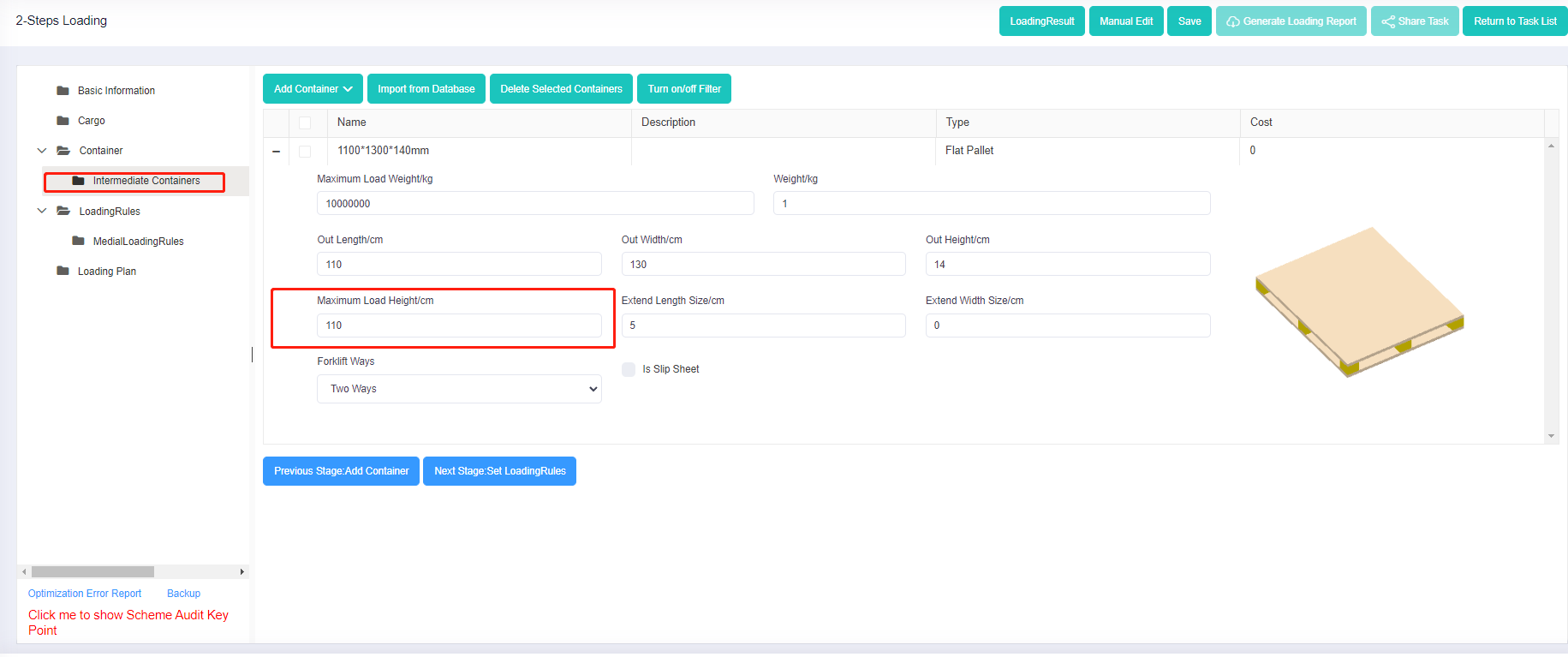

Then click “Intermediate Containers” to add pallets into the LoadMaster. Since the pallet type is uncertain, add those frequently used pallets from database and then set “Maximum Load Height” as 110cm.

Maximum loadable height of the pallet.

Maximum loadable height of the pallet.

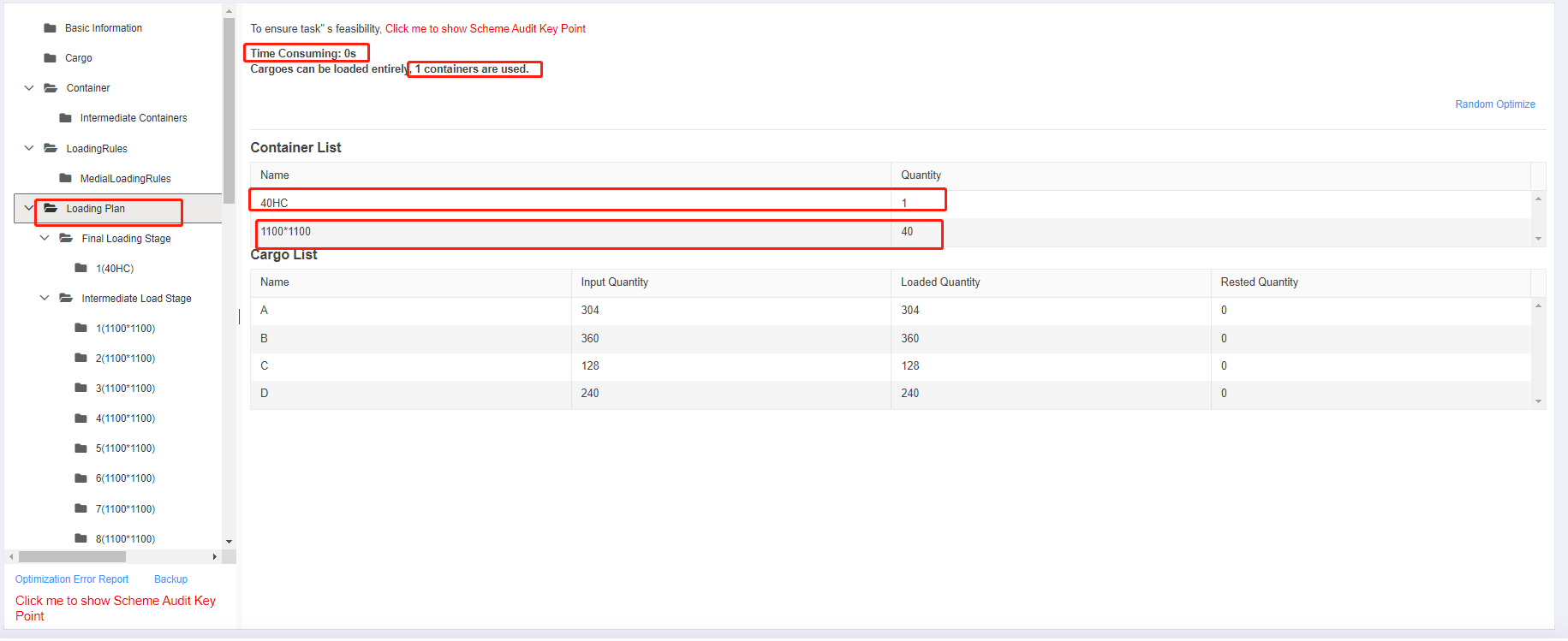

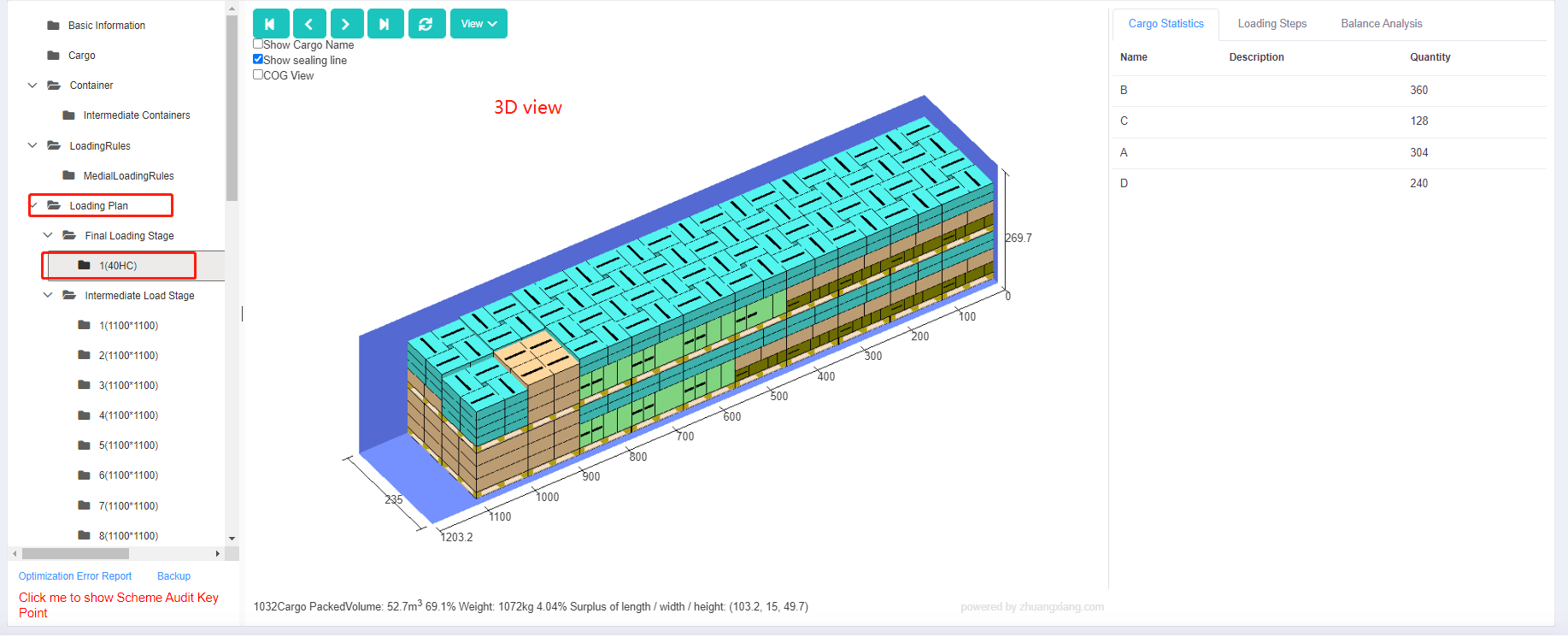

Click “Loading Plan” and you will get an optimal load plan within seconds calculating both pallet loading and container loading.

It can be seen from the left container list that 40 pallets measuring 1100*1100, and a 40GP are used. Click each container and you can see clearly how cargoes are stacked on pallets and in containers.

Loading summary.

Loading summary.

3d load plan diagram

3d load plan diagram