In case of tall cargoes being loaded into containers , if required to be loaded with their height vertical to the container ground, they usually cannot be stacked for one more layer with the same stacking method. For example, refrigerators are very high, if required to be only stacked with height vertical to the container ground, they can solely be loaded for one layer, leading to the waste space on top of this layer. How to make the best use of this remaining space? Under the guidance of LoadMaster shipping container loading software, refrigerators with length or width to the container ground can be stacked on top of the first layer of refrigerators by setting parameters “Support Others” and “Max Stack”. Let’s see how to operate step by step.

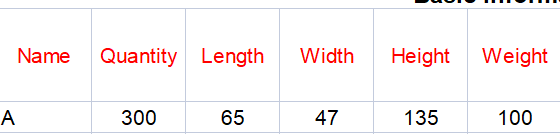

For example, a set of refrigerators are required to be loaded into containers and the cargo information is as follows.

Cargo dimension

Cargo dimension

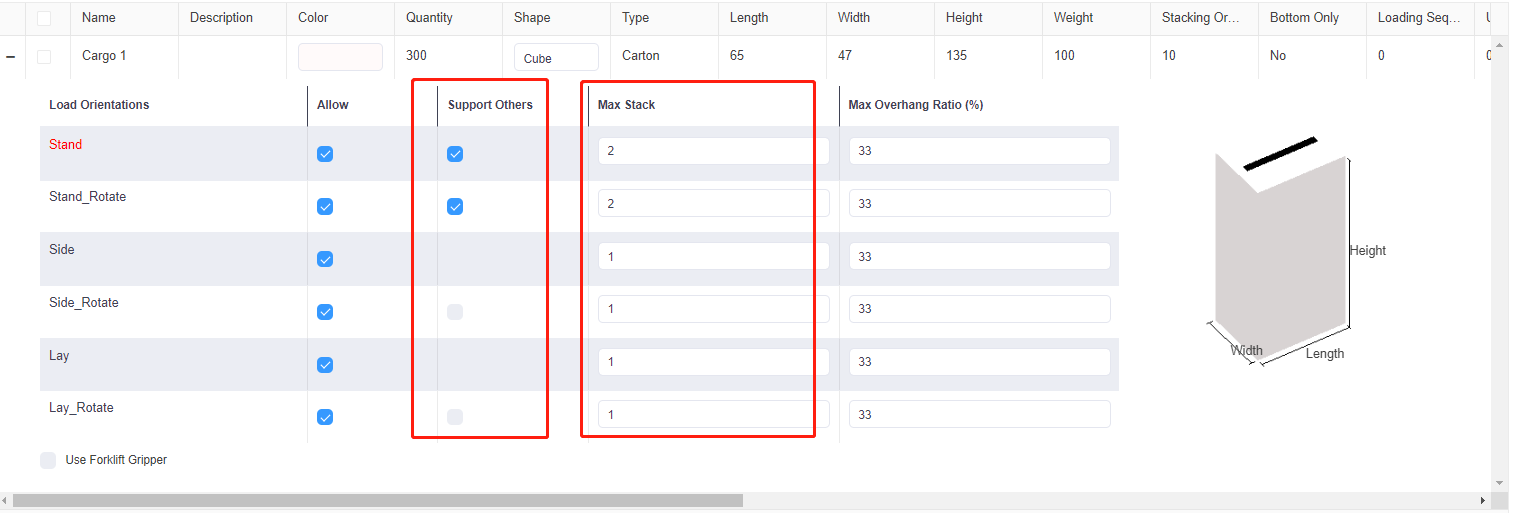

First, fill in the column of “Support Others” with “0” for cargoes loaded with width or length vertical to the container ground, which means other cargoes cannot be stacked on top of these cargoes. Second, fill in the column of “Max Stack” with a suitable number(usually 1 or 2) for these cargoes.

Cargo consttraints: support others and max stack.

Cargo consttraints: support others and max stack.

Then set other parameters and loading rules depending on actual loading requirements.

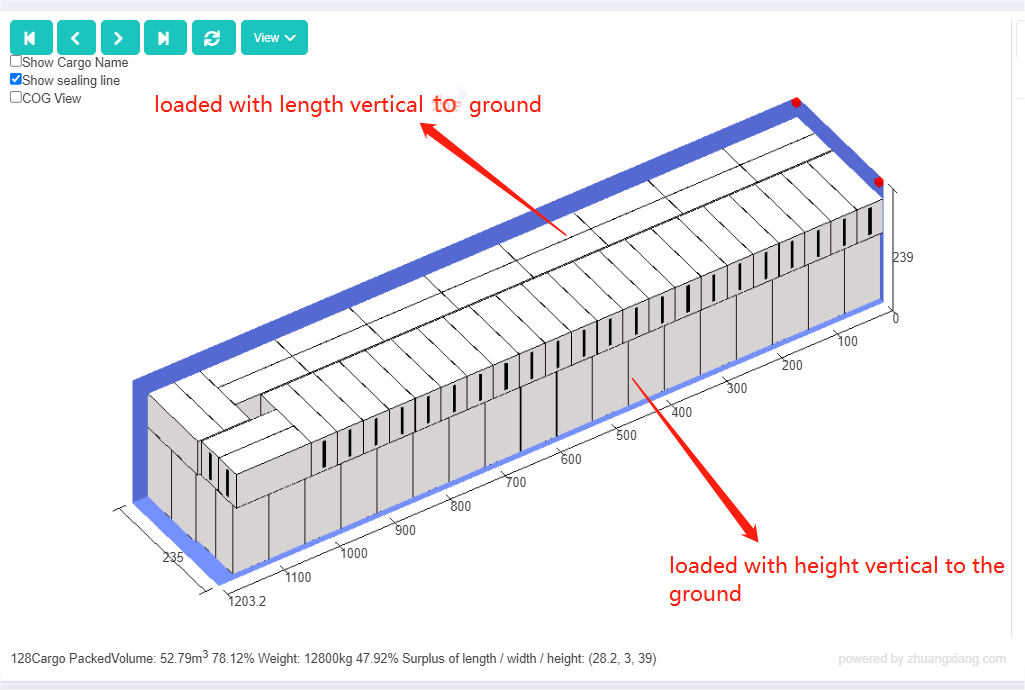

Last click “Loading Plan”, and you can see through the 3D diagram that the bottom layer of cargoes stacked with their height vertical to the container ground and the second layer of cargoes are stacked with their width vertical to the container ground.

Same cargo with different placement orientations.

Same cargo with different placement orientations.