Sometimes, palletized container loading is a better option compared to floor container loading, making it more complicated to calculate both how many cargoes fit in a pallet and how many pallets fit into a container, especially to calculate mixed cargo loading. Under such circumstances, calculating a reasonable load plan is beyond human minds. Let’s see how LoadMaster pallet loading calculator solve this problem.

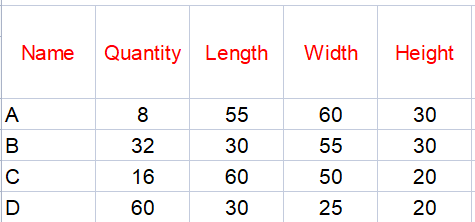

For example, there is an order of cargoes required to be palletized container loading. The cargo information and loading requirements are as follows.

Cargo dimensions.

Cargo dimensions.

Loading requirements:

- Cargoes cannot be placed with their length vertical to the container ground.

- Only Cargo A and Cargo B can be mixed to be placed on one pallet.

- Pallet size is 1100×1300×140mm.

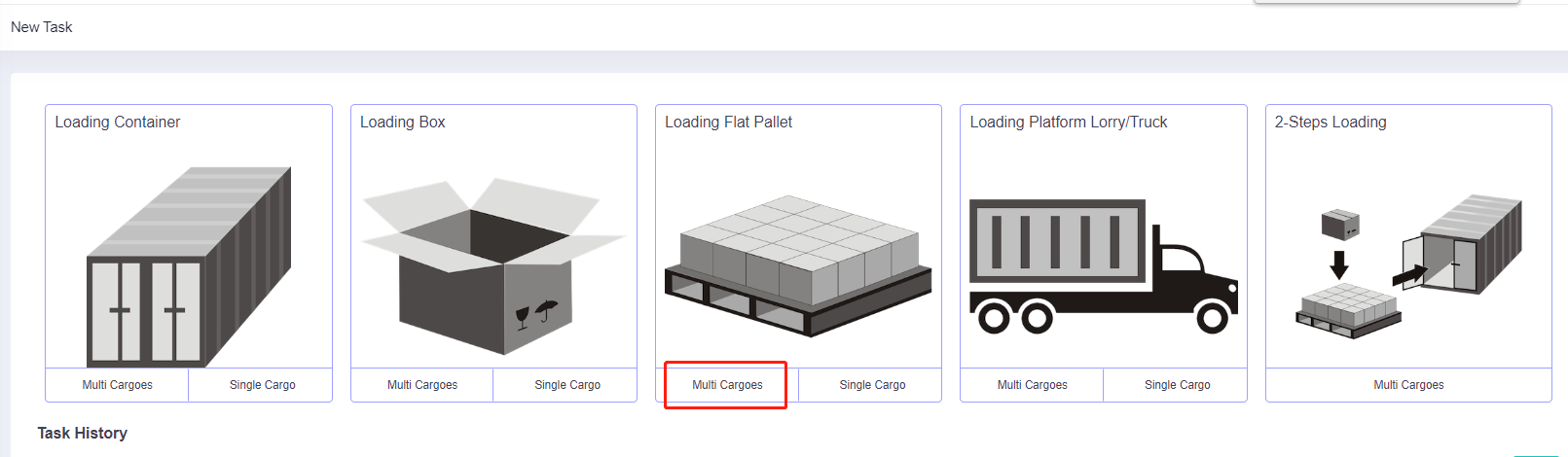

Since it is required to calculate mixed pallet loading. Click “Loading flat pallets-multi cargoes”.

Loading task type: multi cargo pallet loading.

Loading task type: multi cargo pallet loading.

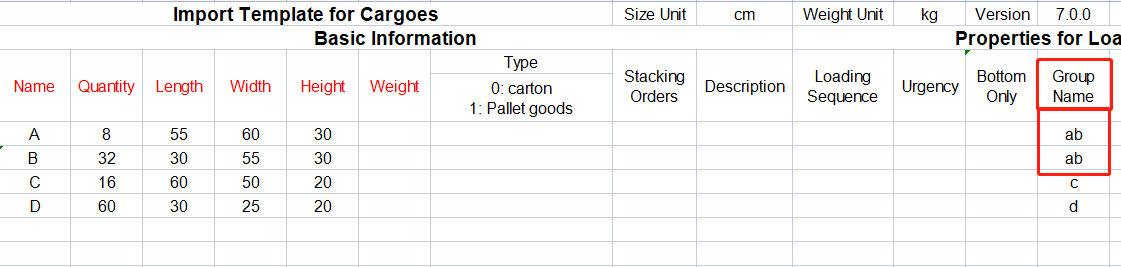

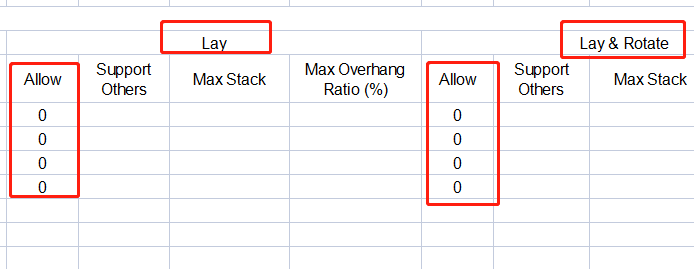

Then choose to add cargoes through Excel template. Since “Cargoes cannot be placed with their length vertical to the container ground”,fill in the columns of “Lay “ “Lay&Rotate” with “0”, which means that they are not allowed to “Lay” and “Lay&Rotate”. Then set the group name of Cargo A and Cargo B as the same such as “ab”.

Set group name in the template.

Set group name in the template.

Disallow “Lay”, “Lay&Rotate”.

Disallow “Lay”, “Lay&Rotate”.

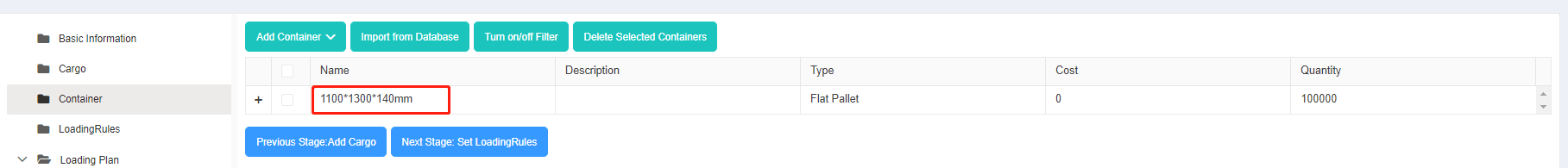

Next add the pallet.

Add the pallet.

Add the pallet.

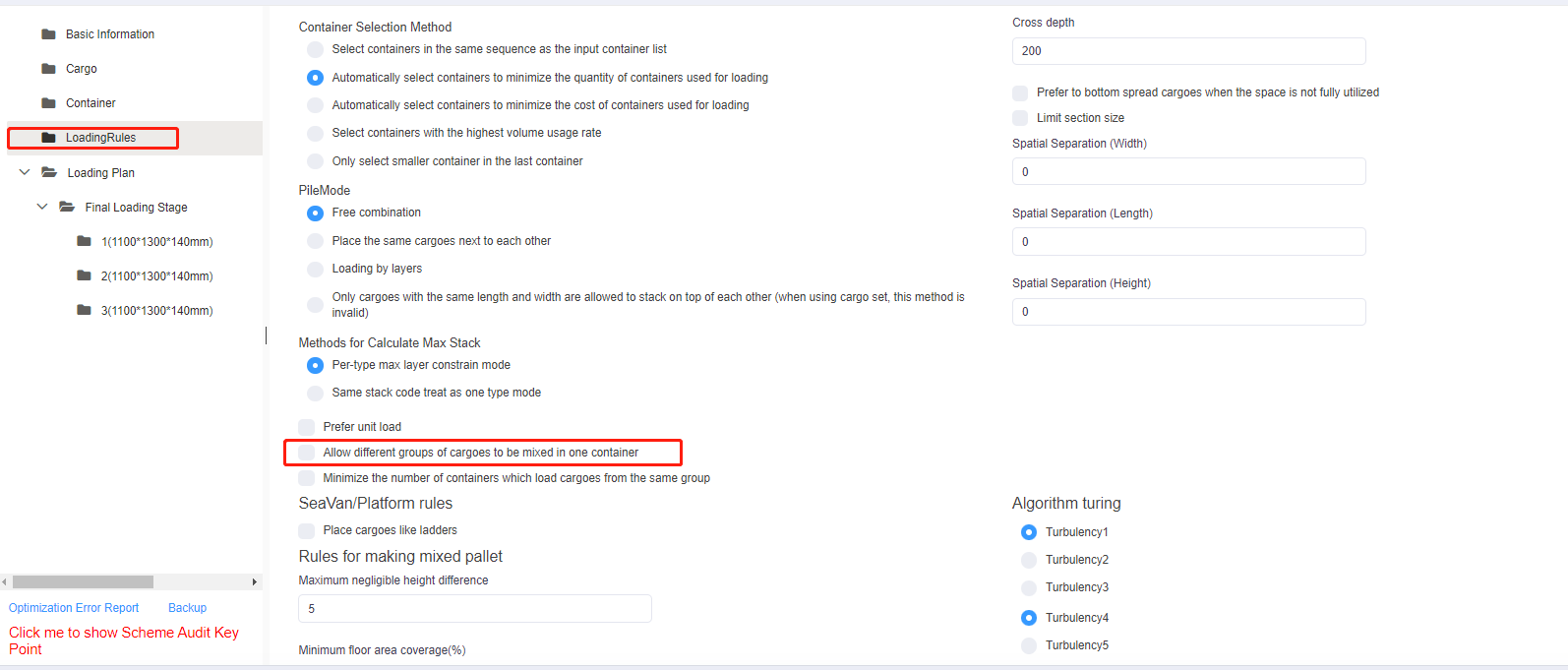

Then set the loading rules. Since only Cargo A and B can be mixed, so uncheck “Allow different groups of cargoes to be mixed in one container”.

Check the rule “Allow different groups of cargoes mixed in one container”.

Check the rule “Allow different groups of cargoes mixed in one container”.

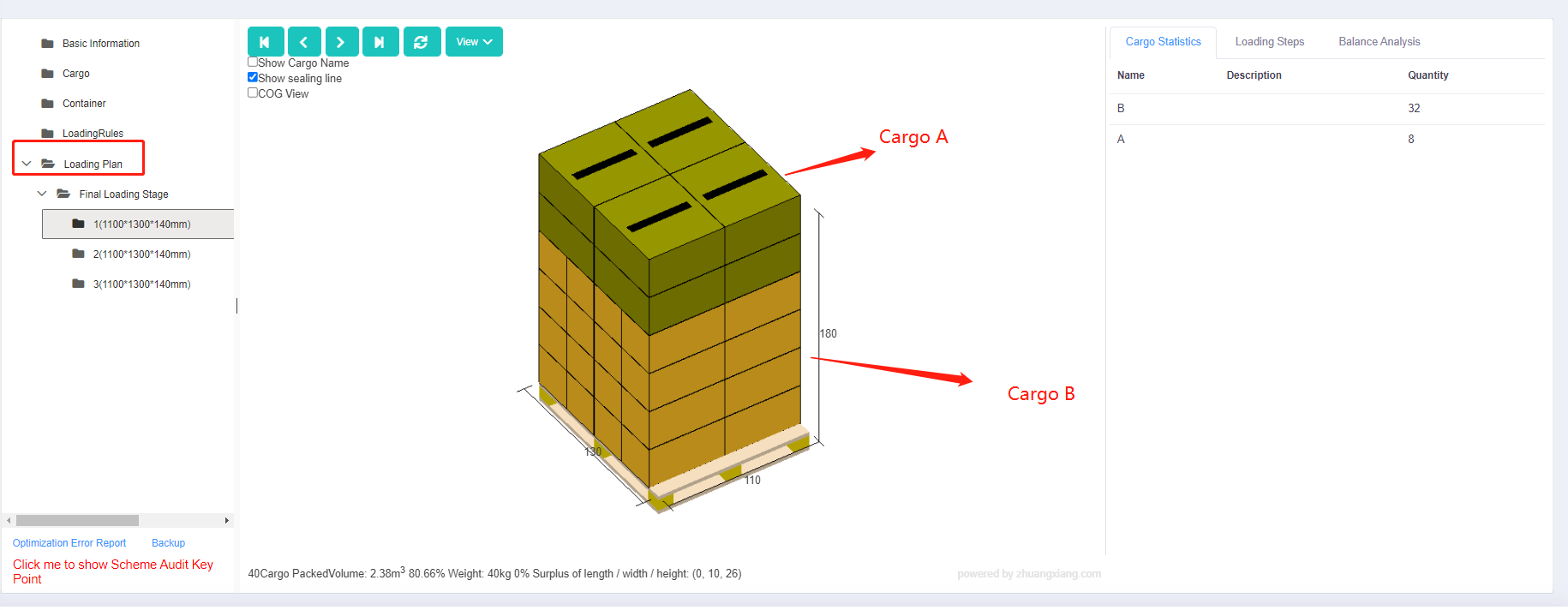

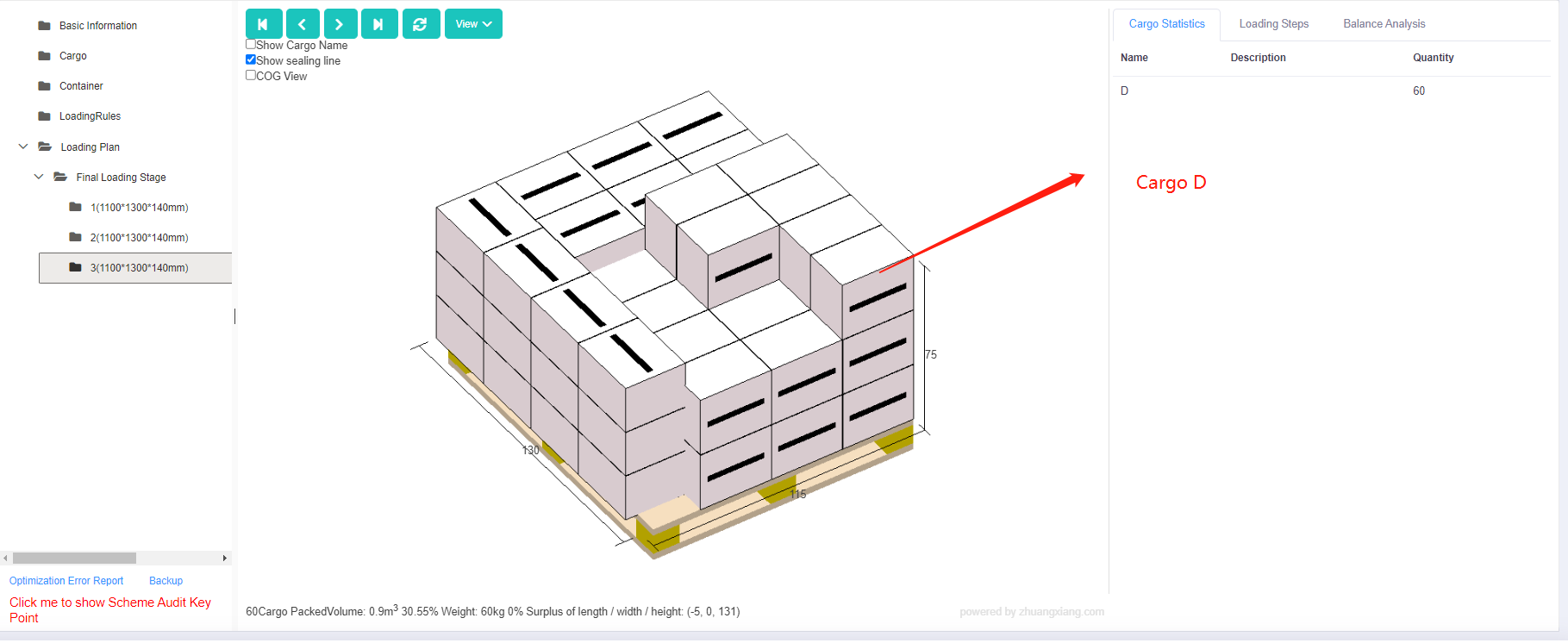

Click “Loading Plan”, and you can get an optimal pallet loading plan within 1 second. Through the 3D interactive view, you can see cargoes are all placed without their length vertical to the ground. And only Cargo A and Cargo B are mixed on one pallet. All loading requirements are met.

Cargo A and Cargo B are mixed on one pallet.

Cargo A and Cargo B are mixed on one pallet.

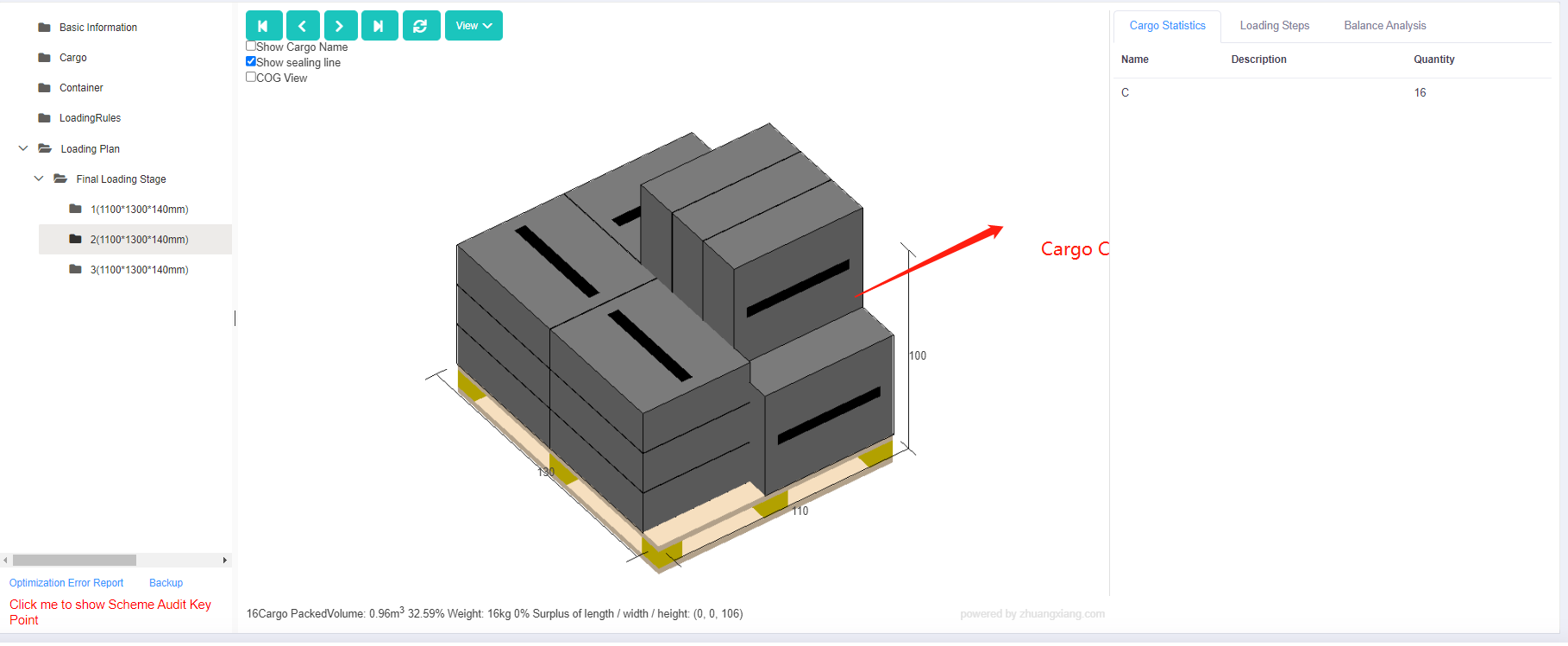

Cargo C on the pallet.

Cargo C on the pallet.

Cargo D on the pallet.

Cargo D on the pallet.