With the diversification of market demands, the manufacturing industry is receiving numerous customized orders of ODM and OEM products. It is crucial to ensure that customized products can all be shipped with the same quantity as the order. Otherwise, they can become stagnant inventory, causing significant losses to the company. So, is there an online container loading software that can help achieve accurate loading?

Palletized cargo waiting to be loaded into a container.

Palletized cargo waiting to be loaded into a container.

Let’s take a look at the share from Mr. Huang in Shatian Hanjun Metal Products Factory about how LoadMaster container loading calculator addressed this issue.

Shatian Hanjun Metal Products Factory, located in Dongguan, is a metal products manufacturing company. It specializes in producing and supplying various high-quality metal products, primarily serving industries such as construction, furniture, automotive, and electronics. With advanced production equipment and extensive manufacturing experience, it possesses strong production capacity and technical expertise.

A metal products factory.

A metal products factory.

Before using LoadMaster, as the company’s finished products were high-value and uniquely designed crafts, it was essential to accurately calculate how many containers would be needed for each order. Otherwise, there was a risk that the containers arranged may not be sufficient to accommodate all the cargoes in the order, resulting in leftover inventory that couldn’t be shipped, causing unnecessary losses.

Stagnant inventory.

Stagnant inventory.

Since the company’s cargoes are bulk cargoes, manual calculation for container loading is laborious and time-consuming, often taking several hours to calculate an optimal load plan. What’s more, manual filling is also time-consuming and hard.

Manual loading on site.

Manual loading on site.

However, as the PIC for production management, Mr. Huang found LoadMaster has made significant improvements in both production management quality and loading speed.

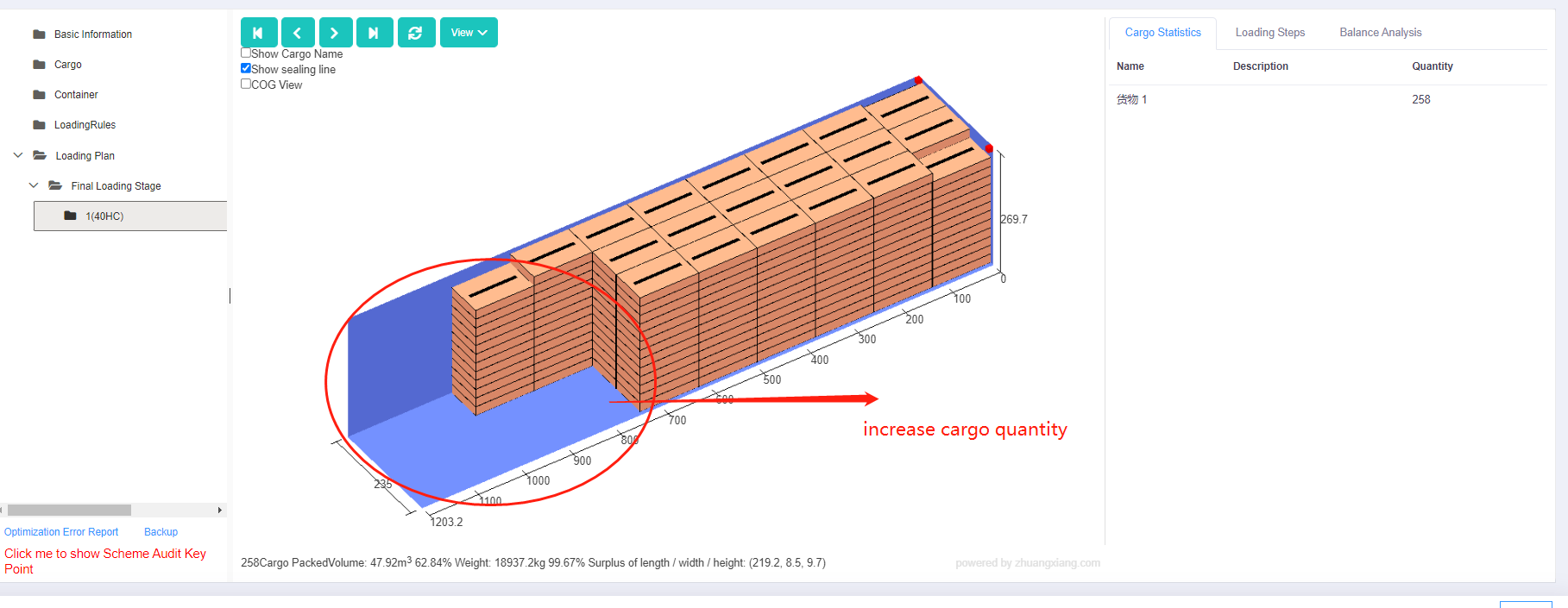

It can calculate an accurate 3D load plan right after a potential buyer has made the order. If there is still remaining space in the container, sales personnel can use the 3D interactive view to communicate with the buyer and recommend the buyer to increase the cargo quantity to make the best use of container space. This is a win-win cooperation, because the seller can have more orders and the buyer can get cargoes with lower shipping costs.

Space where more cargoes can be added in a container.

Space where more cargoes can be added in a container.

LoadMaster has brought us real benefits depending on its professionalism and we decided to cooperate with it in the long term.