Have you ever complained that manual container loading calculation not only consumes time and effort but also has a high risk of errors, resulting in low loading efficiency? In such situations, LoadMaster truck and container loading software can solve all the difficulties you face.

This is people loading cargoes into a container on site.

This is people loading cargoes into a container on site.

When exporting goods from industries such as furniture and hardware manufacturing, different cargoes require different stacking arrangements due to variations in their size and loading capacities. For example, heavier cargoes cannot be placed on top of lighter ones, as it may lead to cargo damage. Additionally, when stacking a great amount of cargoes of different types, it is usually required to stack the same type of cargoes together for the convenience of on-site cargo sorting. How to calculate an optimal load plan meeting all these complex loading requirements?

Cargo waiting to be loaded into a container.

Cargo waiting to be loaded into a container.

What’s more, manual container loading calculation often gives inaccurate quantity of containers needed, which leads to inaccurate container booking, overbooking or underbooking. In case of overbooking, additional round-trip expenses for excess containers need to be paid. On the other hand, underbooking may require rebooking containers, extending the time for loading cargoes, impacting shipping speed, and causing unnecessary losses to the company. How to calculate an accurate load plan to guarantee on-time shipment?

Cargo shipping scene.

Cargo shipping scene.

Haizhige Furniture Manufacturing Co., Ltd. is stuck with this tricky situation. Haizhige is a leading company in the furniture manufacturing industry in Jiangsu Province, China. With a focus on quality and craftsmanship, the company specializes in the production of high-quality furniture for both residential and commercial sectors. It boasts a large-scale production facility equipped with advanced machinery. Let’s take a look at their share!

Different kinds of furniture display.

Different kinds of furniture display.

“While searching for container loading software online, we accidentally discovered LoadMaster and decided to give it a try. During the trial period, we found that this software not only fulfilled the loading requirements of not stacking heavy items over light ones but also facilitated grouping same type of cargoes. Moreover, it enabled accurate container booking, minimizing losses to the company. As a result, we officially started using LoadMaster in 2019 and noticed a significant improvement in work efficiency.

Other experiences we gained from using LoadMaster include:

1.Saving time spent on calculating container loading plans. Previously, it took us two hours to manually calculate a load plan. However, with LoadMaster container loading calculator, we can now complete a plan within minutes.

2.Achieving a container utilization rate of 65 cubic meters in a 40HC, an increase of over 10% compared to manual container loading calculation.

3. Realizing precise booking of containers, avoiding losses caused by underbooking or overbooking.

4. Enhancing container loading efficiency. Pallets are first organized by style based on the 3D loading step diagram. Compared to before, it only takes about an hour to complete the whole loading process, an increase of 50% of working efficiency.”

Loading staff loading cargo on site.

Loading staff loading cargo on site.

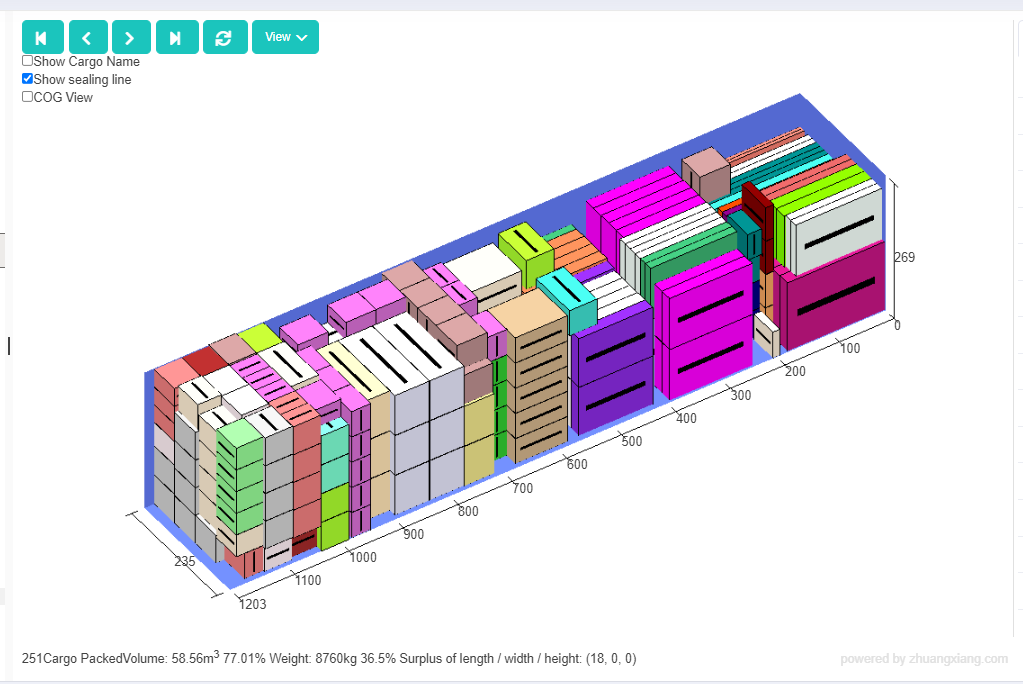

3d load plan display

3d load plan display

Check how we can help furniture industry at https://blog.loadmaster.biz/2023/11/03/41/