Hisense is a prominent player in the consumer electronics industry and has established itself as a global leader. Hisense TV is a leading brand under Hisense. It specializes in manufacturing and selling a wide range of high-quality televisions. With a strong market presence and extensive product offerings, Hisense TV has established itself as a competitive player in the industry.

Hisense website screenshot.

Hisense website screenshot.

Nowadays, the volume of exported loose cargo orders is increasing, and each market has specific requirements for container loading. Before using LoadMaster online container loading optimization software, we use manual container loading calculation. Manual calculation of container load plan is time-consuming and inaccurate, and it cannot cover all orders. In the past, the number of containers ordered was based on past experience, often resulting in overbooking or underbooking, which greatly affected delivery time. On-site container loading relied on the experience of filling personnel, often leading to temporary adjustments during the loading process. What’s worse is that some certain cargo is found to be loaded into the container by mistake and then the whole container of cargoes need to be unloaded and reloaded. There are also occurrences of incorrect loading, missing pieces, left not-loaded cargoes, and insufficient containers. Therefore we wonder if there is an online container loading optimization software that can help us and meet the following loading requirements.

Considering our current loose cargo export plan and the specific container loading requirements in the market, the container loading software needs to meet the following requirements:

- Able to calculate both pallet loading and container loading plan.

- Capable of importing data in batches, enabling simultaneous pallet loading and container loading.

- Support for calculating different groups cargoes to be loaded onto pallets and into containers.

- Manual edit for temporary changes.

- Set placement orientation and location according to different loading capacities, loading priority and so on.

- Output of palletizing and container loading plans in the form of Excel spreadsheets, including packing list and loading steps.

- User-friendly interface and easy to learn and operate.

We feel very fortunate to work with LoadMaster which has brought our company numerous real benefits.

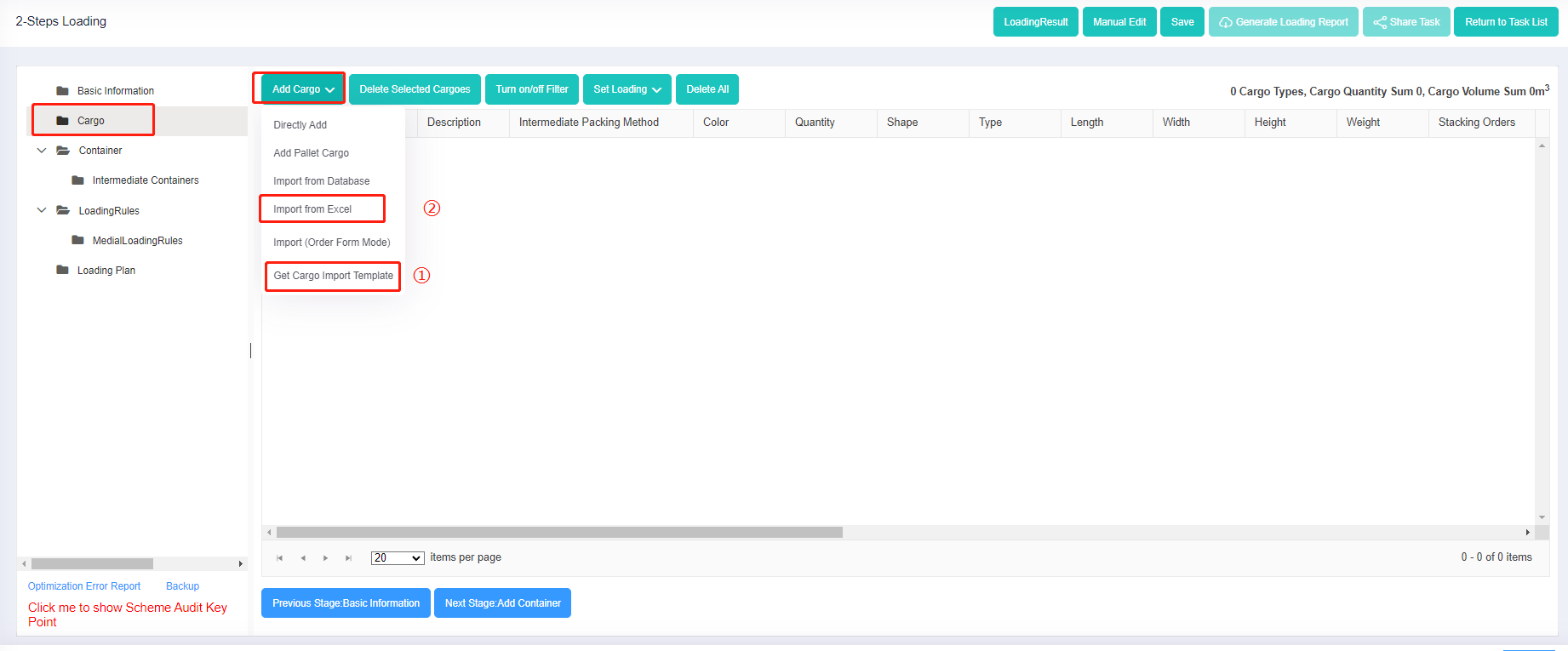

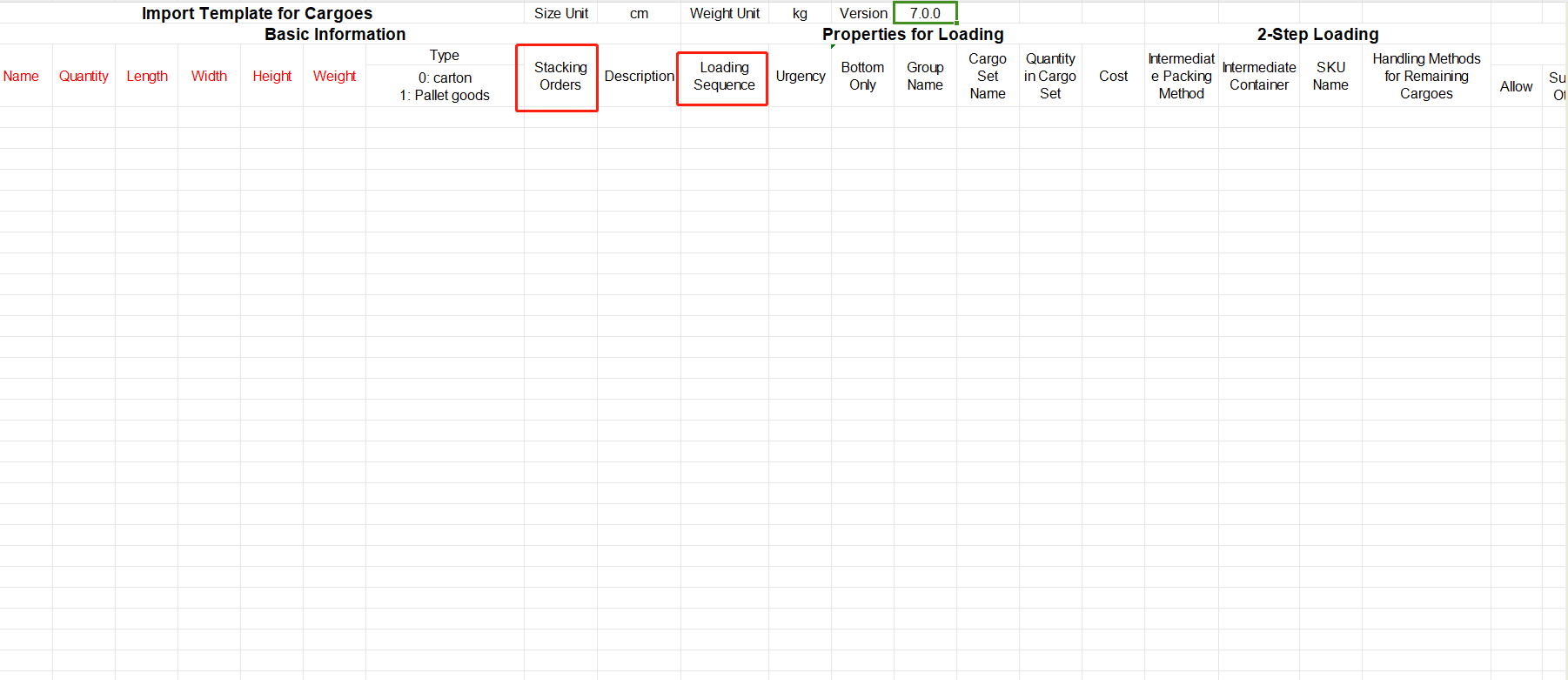

First, cargo data can be imported in batches through Excel template and we can set parameters in the template to meet some loading requirements.

Add cargo through excel template.

Add cargo through excel template.

Parameters Stacking Orders and Loading Sequence.

Parameters Stacking Orders and Loading Sequence.

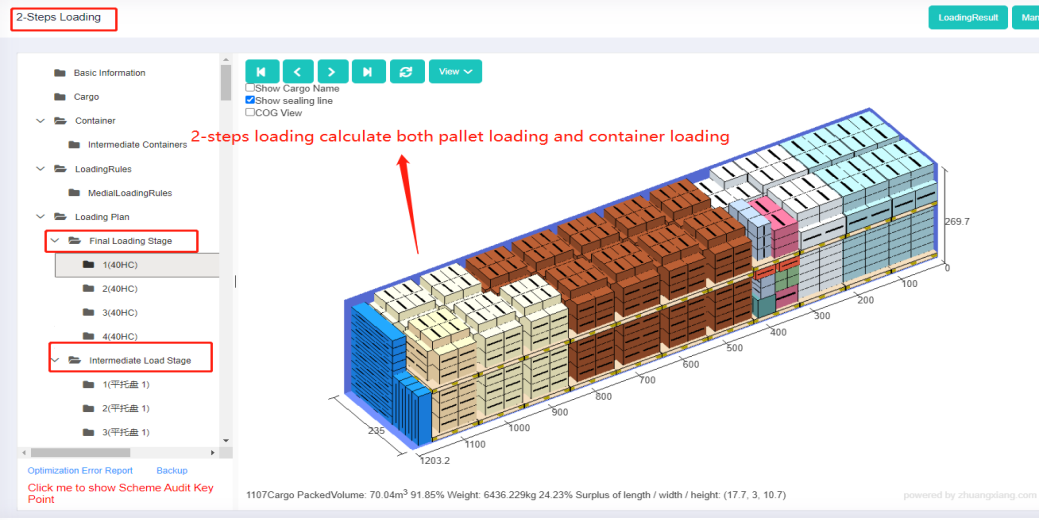

Second, “2-steps Loading”combines both pallet loading calculation and container loading calculation and can offer a load plan including both pallet loading and container loading, greatly improving the working efficiency.

A 3d two-steps loading plan.

A 3d two-steps loading plan.

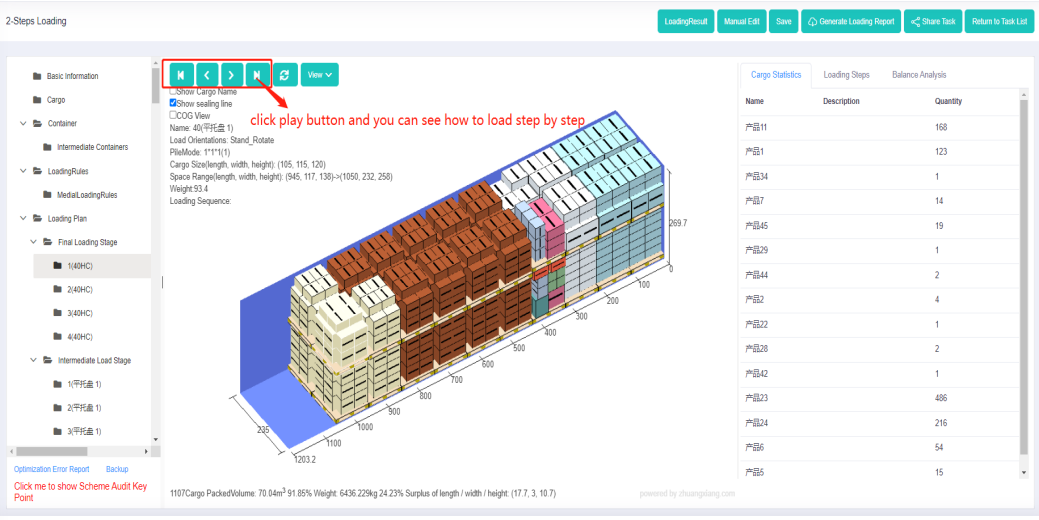

Third, clear 3D step-by-step interactive diagram can be used to guide on-site loading. And load plans can be exported in the form of Excel spreadsheets, including packing list and loading steps. Last but not least, the manual edit can adapt to some temporary container loading changes.

Play buttons to click to display step-by-step loading.

Play buttons to click to display step-by-step loading.

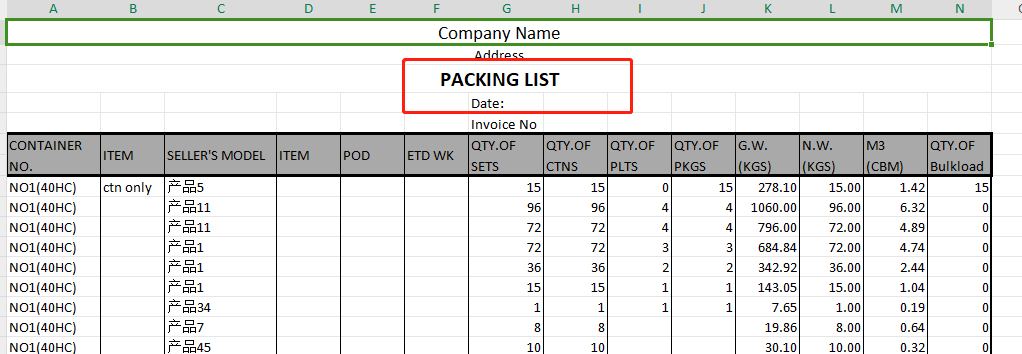

Packing list report.

Packing list report.

In short, LoadMaster software fully meets our loading requirements and significantly reduces the workload of manual calculations, enabling accurate loading and step-by-step guidance for on-site container loading. In the future, as the optimization of loose cargo operations and advancement of packaging standardization, LoadMaster will bring greater convenience to the production and container loading of loose cargo.

Check how we can help home appliances industry at https://blog.loadmaster.biz/2023/11/02/40/