During shipping container loading process, it is crucial to avoid cargo damage and ensure the safe transportation of cargoes. Especially when loading different kinds of cargoes with various sizes, it’s difficult to calculate how load these cargoes in a reasonable way solely depending on human minds. So, how can we achieve safe and secure loading when calculating the load plans? Let’s take a look at how LoadMaster, the load plan&optimization software makes it via the following methods.

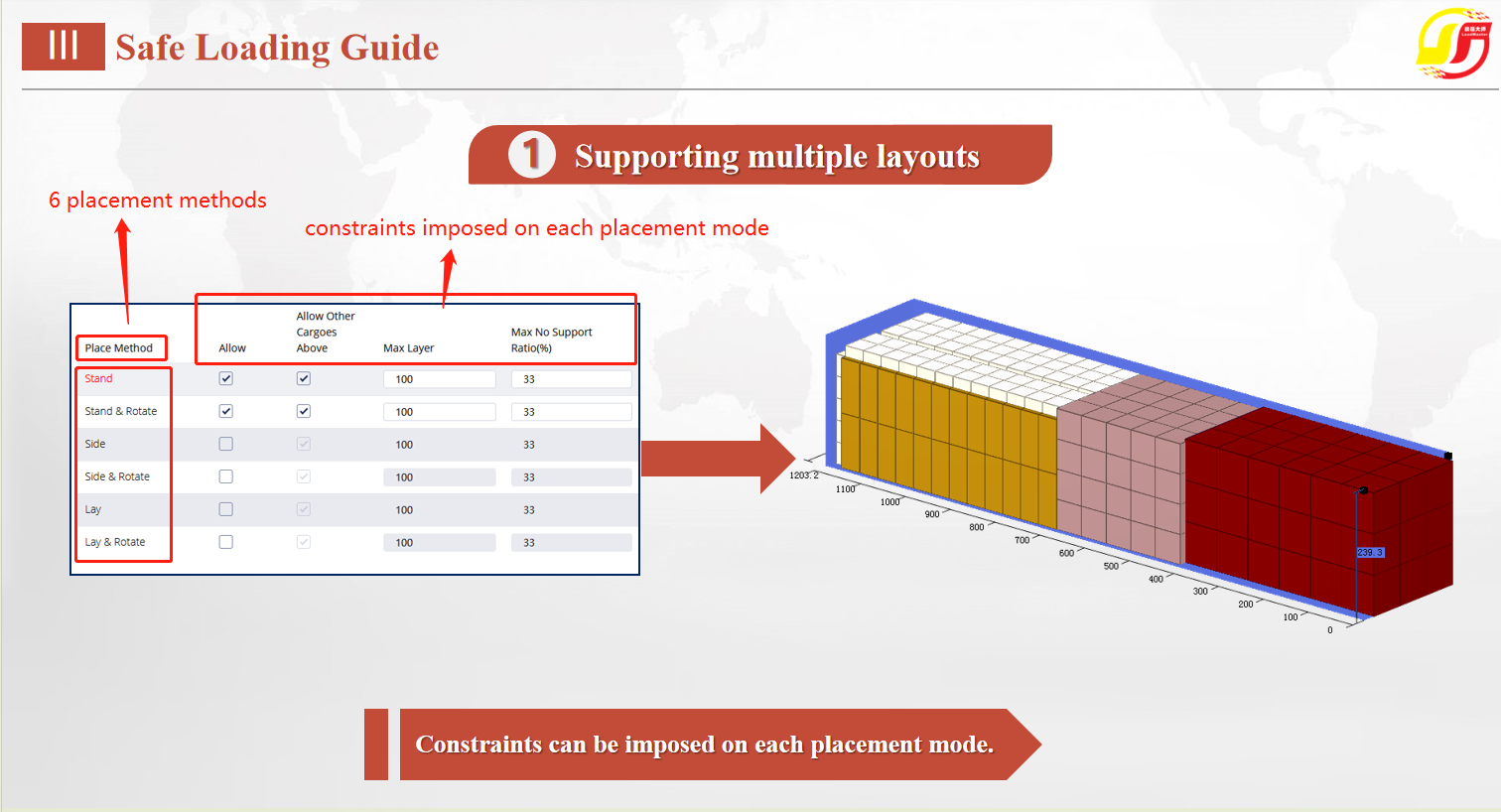

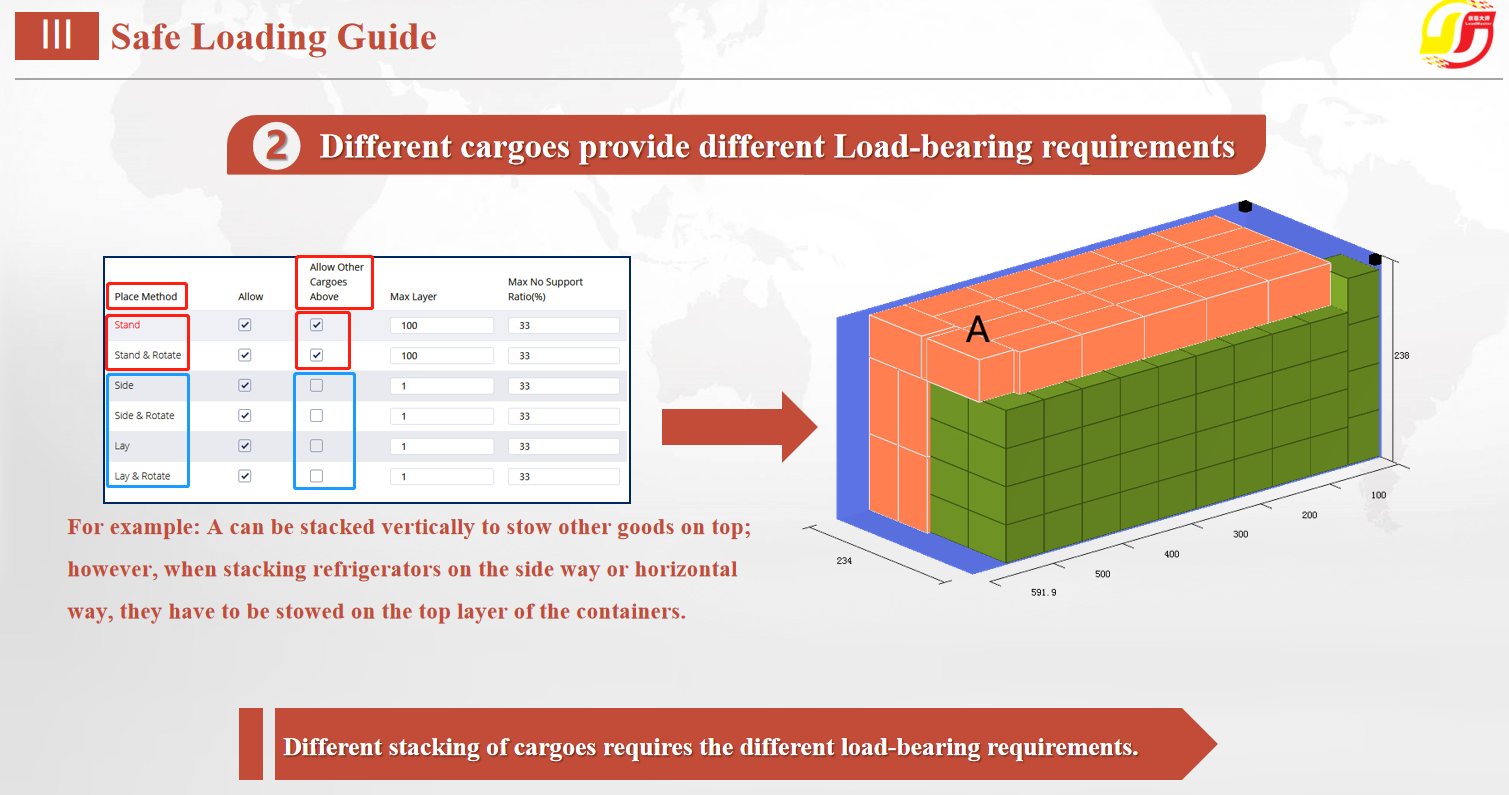

First, LoadMaster, the online load plan&optimization software, offers six different layouts or stacking placement methods. Under different placement methods, even the same cargoes have different load capacities. LoadMaster load plan&optimization software can intelligently calculate the most reasonable placement method for each cargo based on their load capacities. For example, refrigerators have a stronger load capacity when placed with their height vertical to the container ground, but a weaker load capacity when placed with their width vertical to the container ground. Under such circumstance, we can set different placement methods for refrigerators to avoid cargo damage.

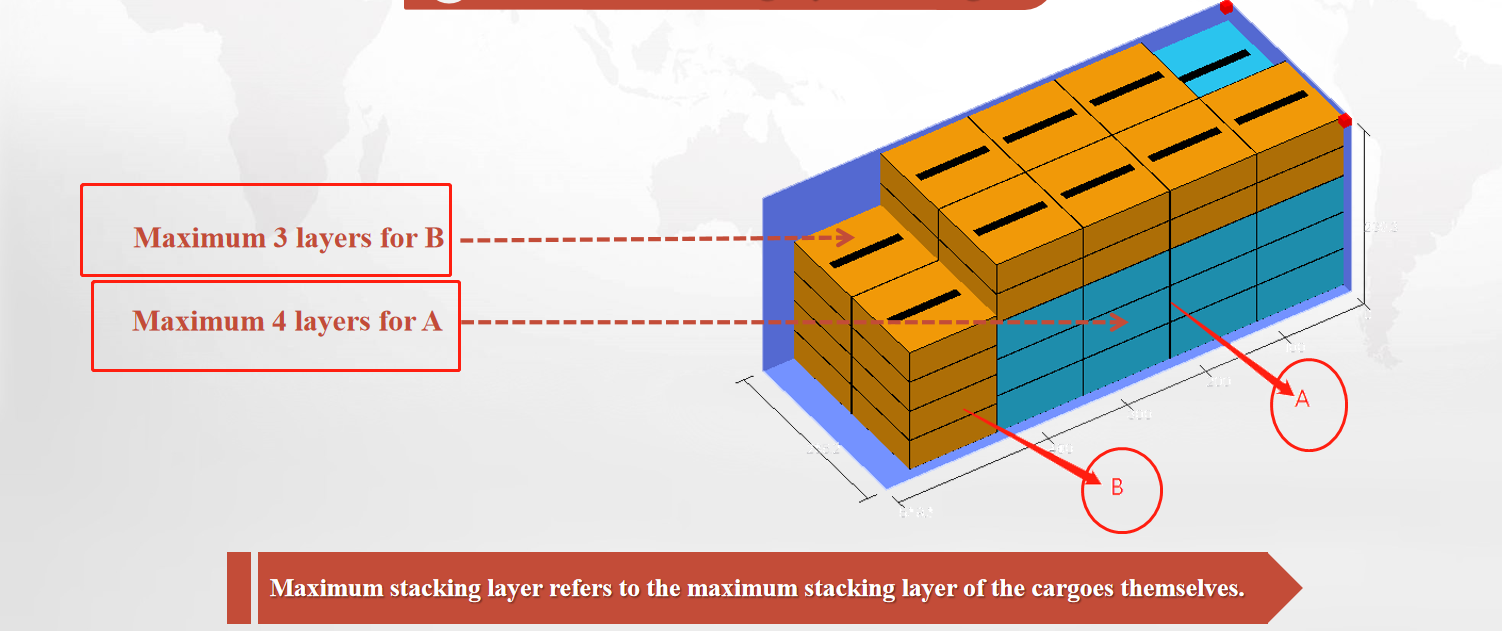

Second, load capacities of different cargoes determine their maximum stacking layers. In the software, you can set the “Max Stack” parameter to limit the stacking layers of cargoes themselves.

Third, when container loading requirements involve considerations such as weight distribution, preventing heavy cargoes from crushing lighter ones, or preventing larger cargoes from pressing smaller ones, you can set “Stacking Orders” based on factors like “Gross Weight,” “Density,” or “Packaging Type.”

Fourth, certain cargoes may be only allowed to stack by themselves but not other types of cargo. In such cases, you can meet this loading requirement by unchecking the option “Support Others”.

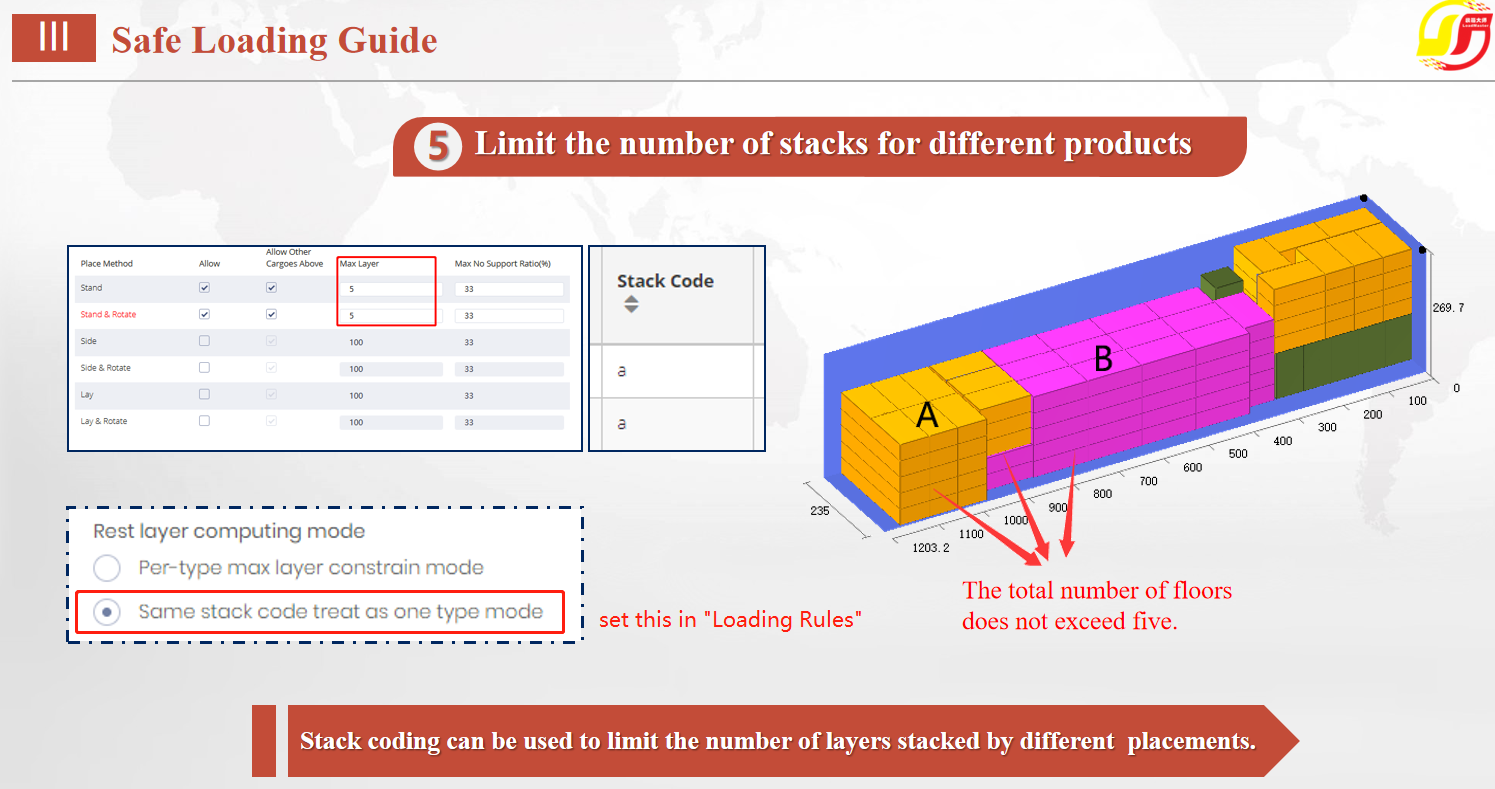

Fifth, the “Stack Code” combined with the “Max Stack” parameters can be used to limit the total stacking layers when different cargoes are stacked together. By setting the same “Stack Code” and “Max Stack” for different cargoes, LoadMaster load plan&optimization software will treat them as the same type of cargo when calculating the maximum stacking layers.

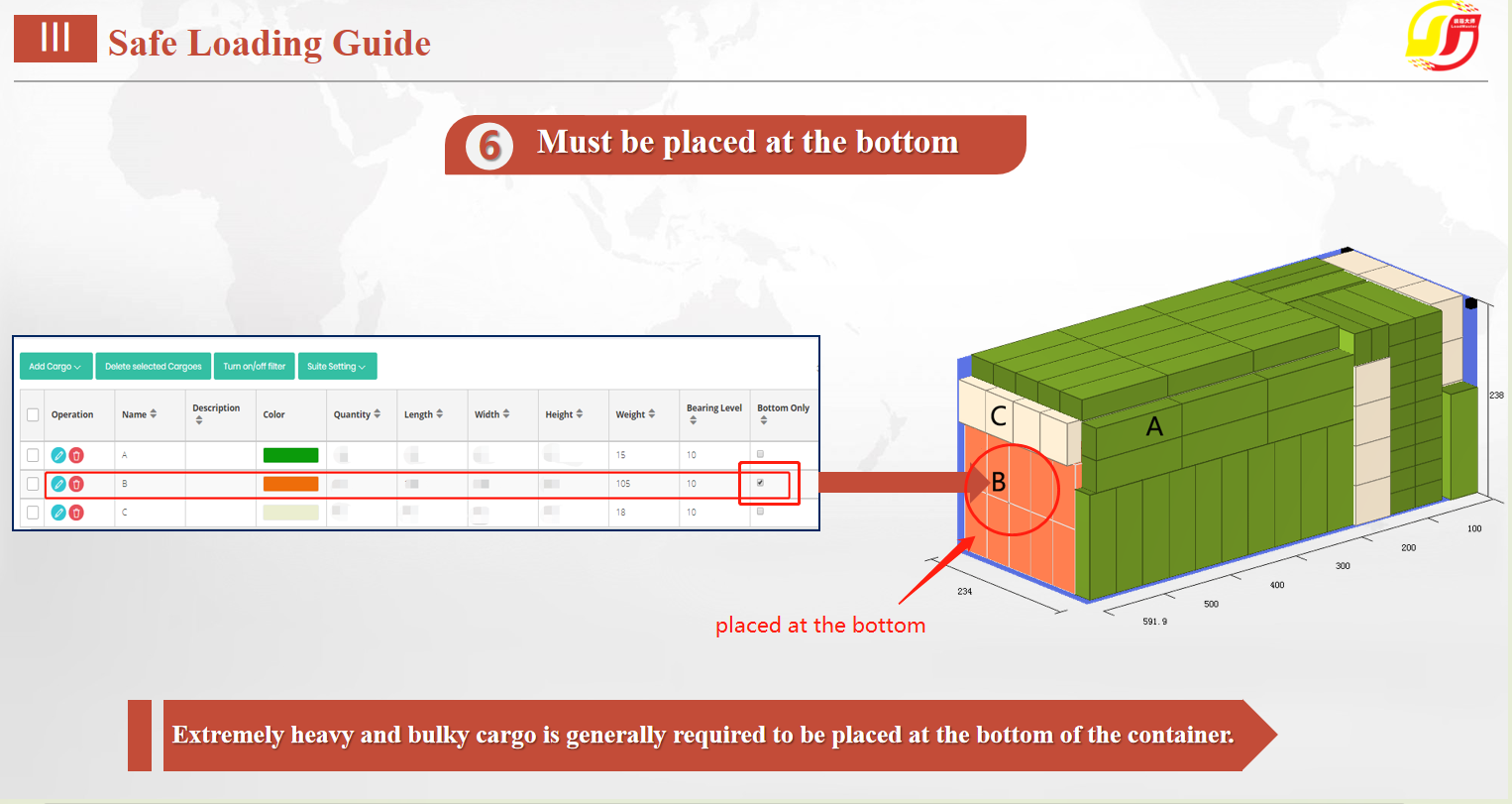

Sixth, when dealing with heavy cargoes, you can set “Bottom Only” to allow them only be placed at the bottom. Please note that after setting this parameter, they can still be stacked by themselves. If you want to limit the cargo to just the bottom layer, you should also set its “Max Stack” to 1.

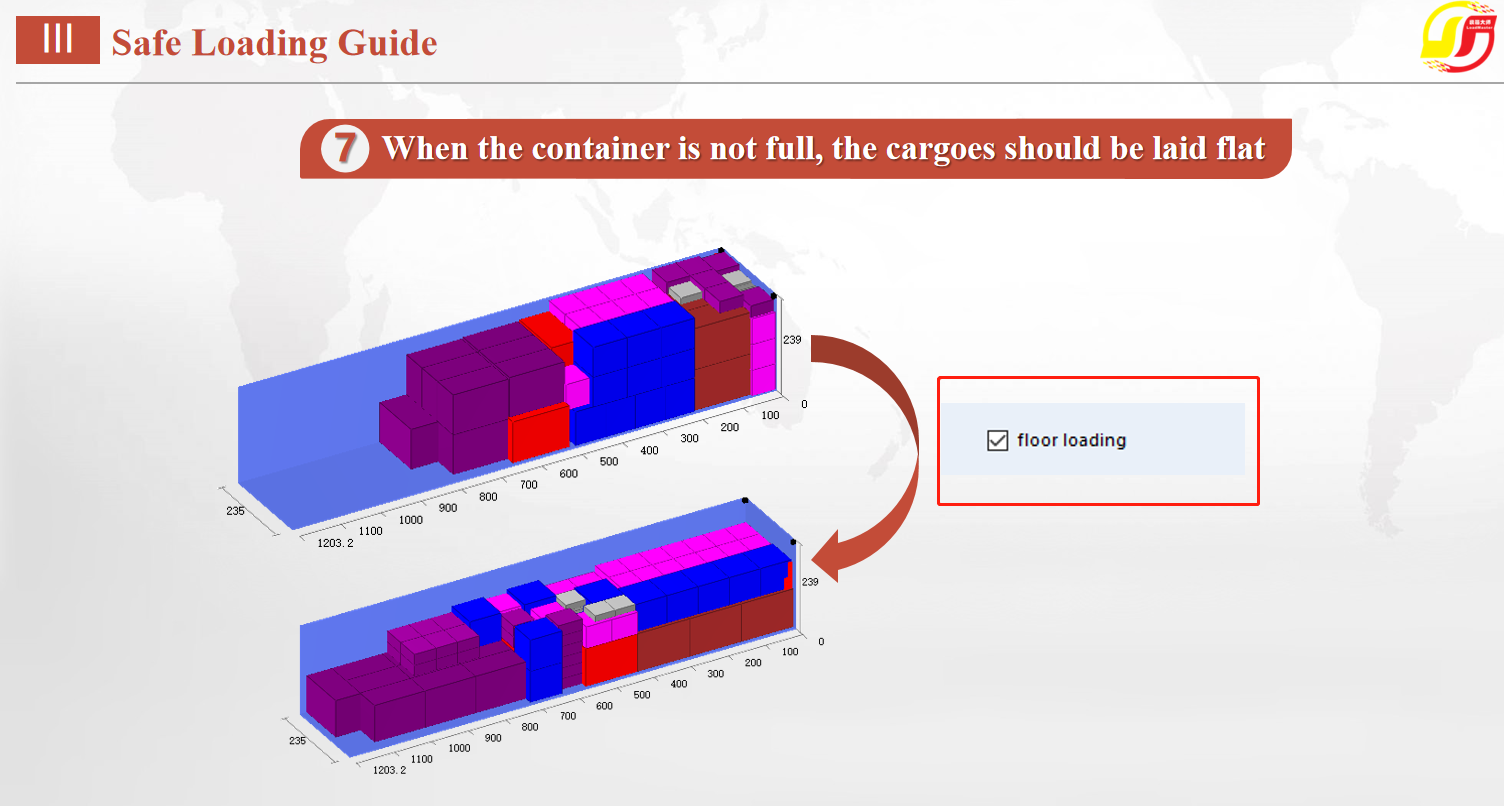

Seventh, when there is a small amount of cargo that cannot fill the entire container, there is a risk of cargo damage during transportation. In this case, you can try to spread the cargo as flat as possible within the container, distributing the cargoes in the container to fill in the remaining space.

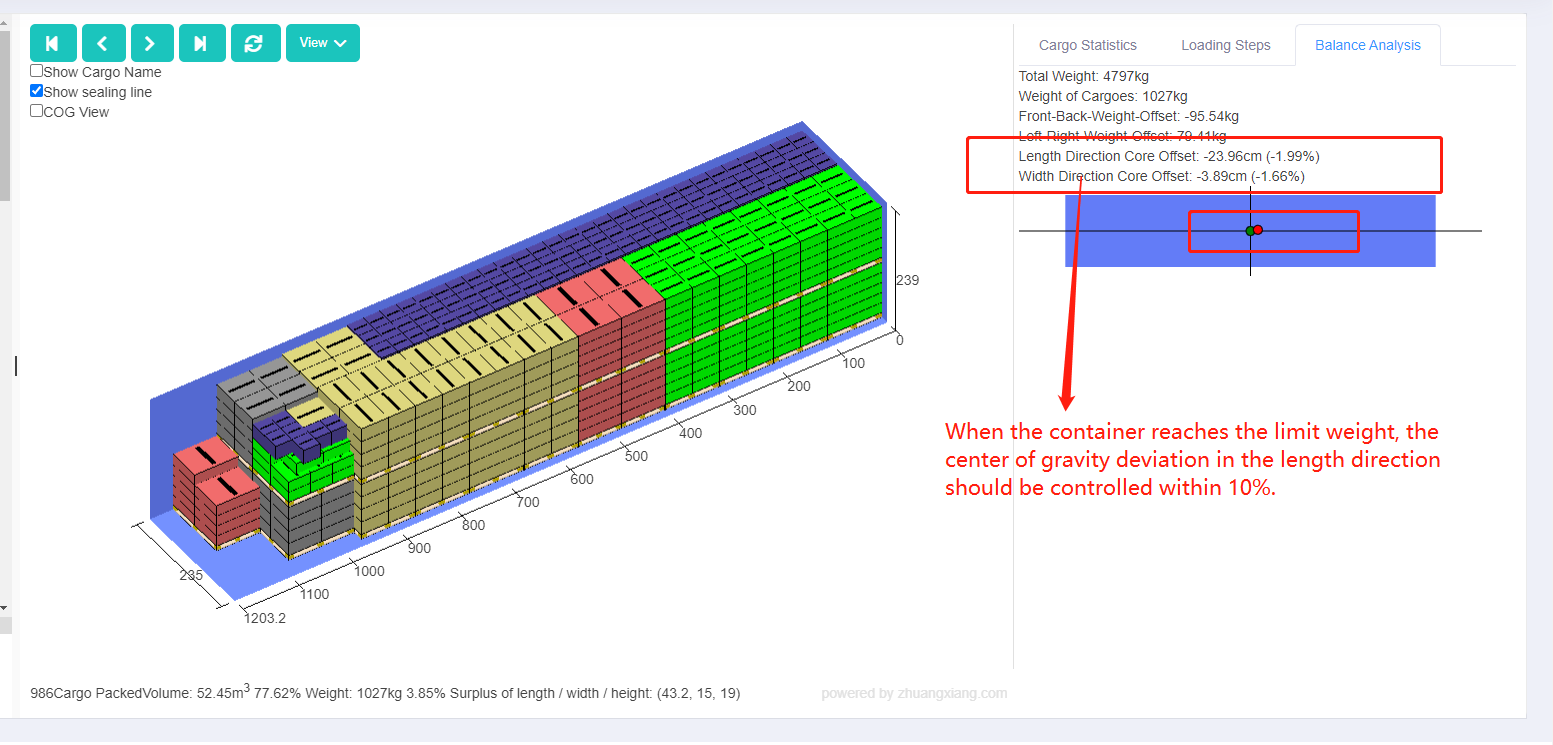

Eighth, the LoadMaster online load plan&optimization software also provides the the analysis of the container balance. Through manual edit, you can adjust the center of gravity to reduce the cargo damage.