APL Logistics is a world-famous third-party logistics (3PL) provider, aiming to provide customers with global end-to-end supply chain services across Automotive, Consumer, Industrial and Retail markets. APL Logistics (China) Co., Ltd. Shenzhen Branch, a branch of APL Logistics in Shenzhen, China, undertakes the international transport agency business of the imports and exports from sea, land and air, international exhibits, personal items and transit cargoes. APL Logistics in Shenzhen now is one of the top 100 logistics enterprises in China. Since 2016, we have been working with LoadMaster container packing software for 7 years.

You may wonder why do we choose LoadMaster to be a partner? What kind of benefits can it bring to our company? Let’s check it out!

Before using the container packing software LoadMaster, APL Logistics in Shenzhen calculated load plans through Excel spreadsheets, and then the staff of warehouse loaded cargoes into containers according to the load plans and experience from masters. In this way, working efficiency is quite low while the error rate is very high. In addition, it’s extremely difficult for a human being to take all into consideration including carton types, sizes and weight together with the utilization rate of containers, which results in a quite low container utilization rate or even worse, the unnecessary reloading costs because of overload.

However, with the help of LoadMaster load calculator, the container utilization rate has been uplifted to a great extent. By optimizing the placement of cargoes in containers, the volume available to be loaded of a 40HC has been improved from 65CBM to 71 CBM, and as for that of a 40GP, increasing from 55CBM TO 59CBM. On average, the container utilization rate can arrive above 95%, higher than manual loading by 7%-9%, resulting in a lower freight cost.

Due to the disadvantage of manual loading experience such as the incapability of controlling irregular carton sizes, containers may not accommodate all the cargoes which by human calculation can all be loaded into containers, leading to a high rate of reloading. However, the utilization of containers can be expected ahead of on-site loading under the guidance of the 3D diagram offered by LoadMaster container loading software, reducing the reworking rate.

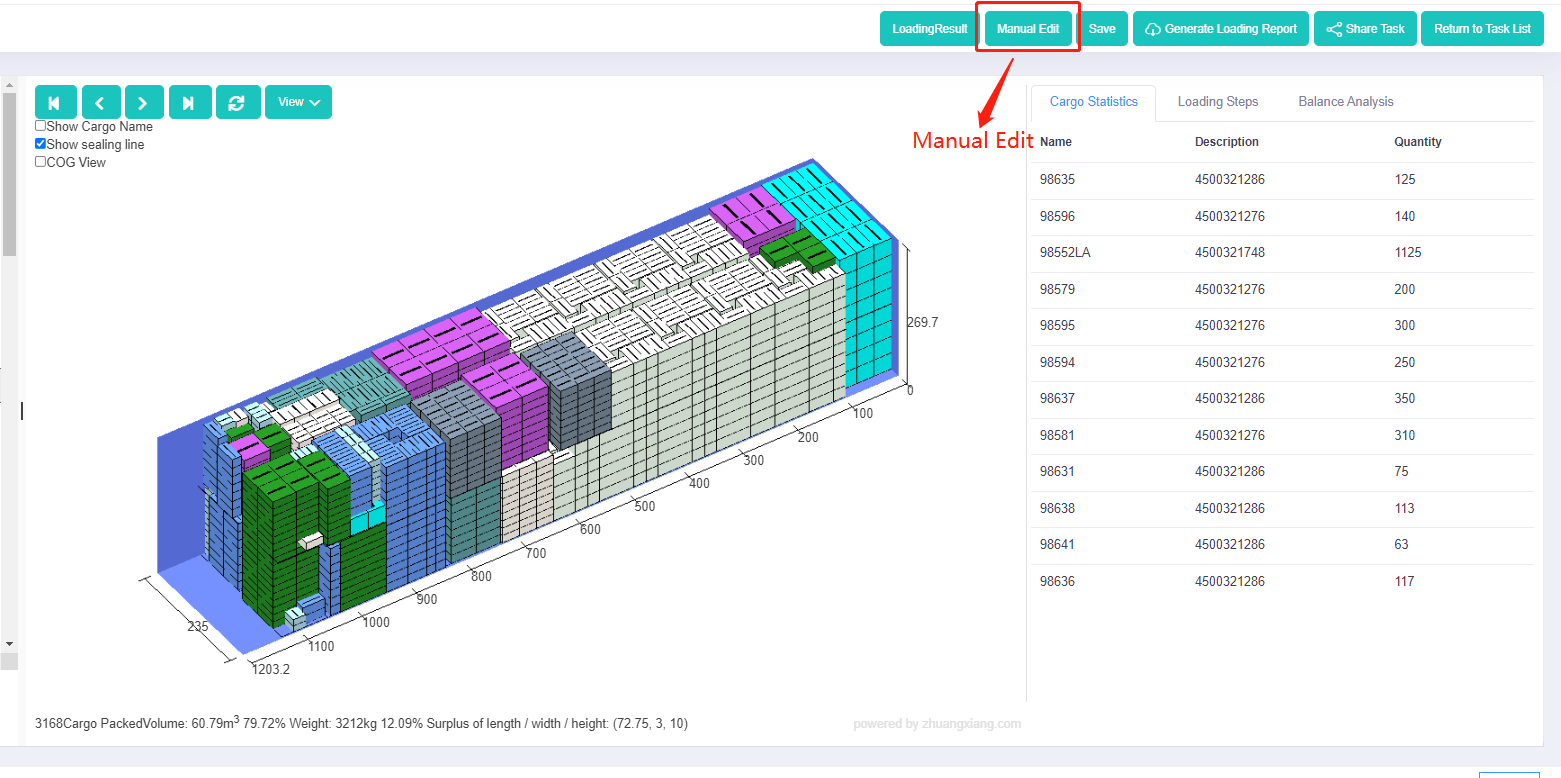

What’s more, assisted by the manual edit which can meet our special loading requirements, the 3D diagram together with loading steps guide is very helpful in guiding on-site loading.

Last but not least, the customer service of LoadMaster container packing software is excellent and considerable, offering patient remote presentation of software operation, Q&A, and customer visits through the whole process, making us feel warm and cherished.

Do you want experience the great benefits from the container packing software LoadMaster? Do you want to increase your company’s working efficiency to a large extent? Come and apply for a 30-day free trial of LoadMaster!