Philips (China) Investment Co., Ltd is a leader in the lighting industry with its products sold to the whole world. And these products of various types are widely used in offices, streets, stadiums, public buildings, shopping centers, business and home lighting. Today, 30% of the world’s offices, 65% of the top airports, 55% of the major football stadiums and 30% of the hospitals are enjoying professional lighting service from Philips. At present, our company has a number of production bases and R&D centers across the country, and the company’s scale and strength are in the forefront of the industry. Philips currently holds approximately 75,000 patents, 22,000 registered trademarks and 6,000 registered designs. Since 2015, Loadmaster container loading software has been working with Philips (China) Investment Co., Ltd for 8 years.

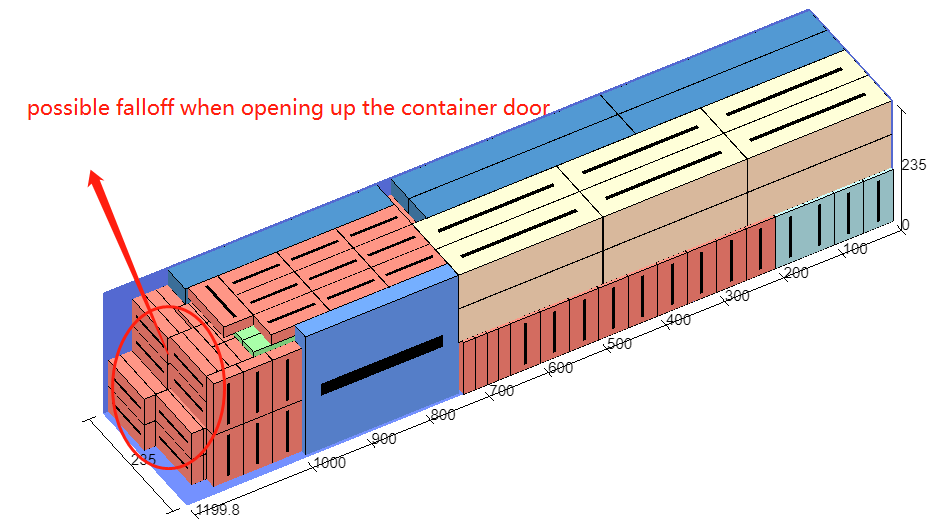

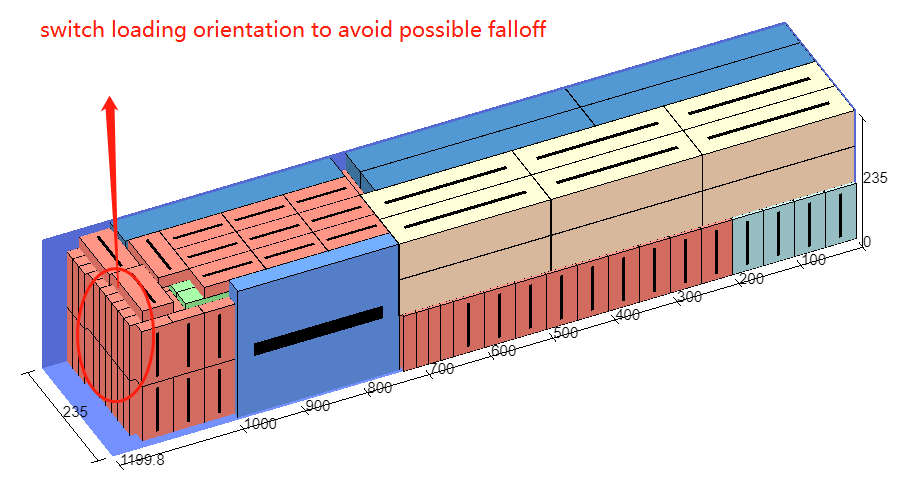

As a huge company, our products are very diverse and of various sizes. Out of different loading capacity, these products, namely cargoes to be loaded, should be loaded into the container according to certain requirements, such as cargoes placed relatively below should be put with their height vertical to the ground and cargoes placed relatively above others should be put with their length vertical to the ground. In addition, the layers and the order of being stacked are also restricted. Under such circumstance, there is a rare chance for even experienced masters to offer accurate loading solutions in a short time. And even if possible, mistakes hard to avoid may cause the whole loading process redone, resulting in unnecessary costs. Therefore you may wonder is there any possibility that Loadmaster container loading software can deal with all these disturbing requirements rapidly?

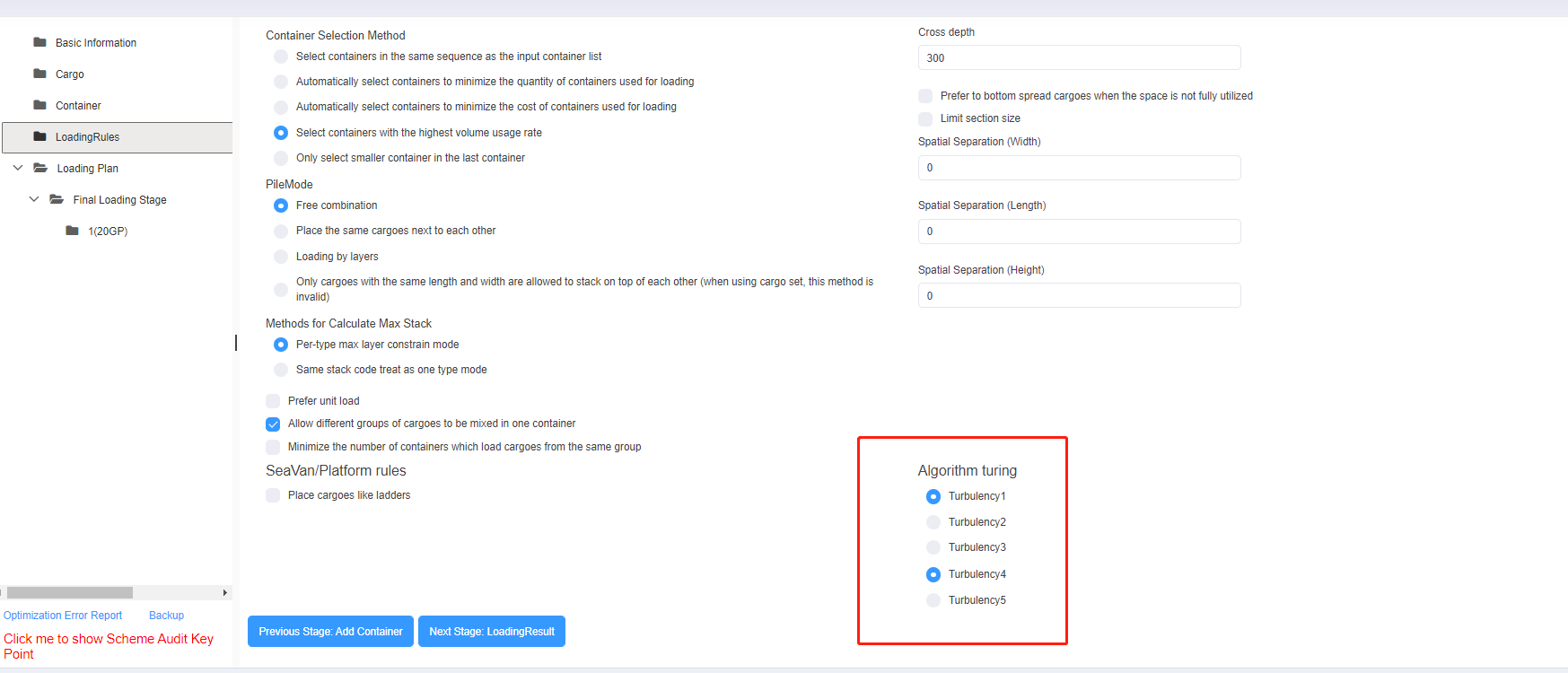

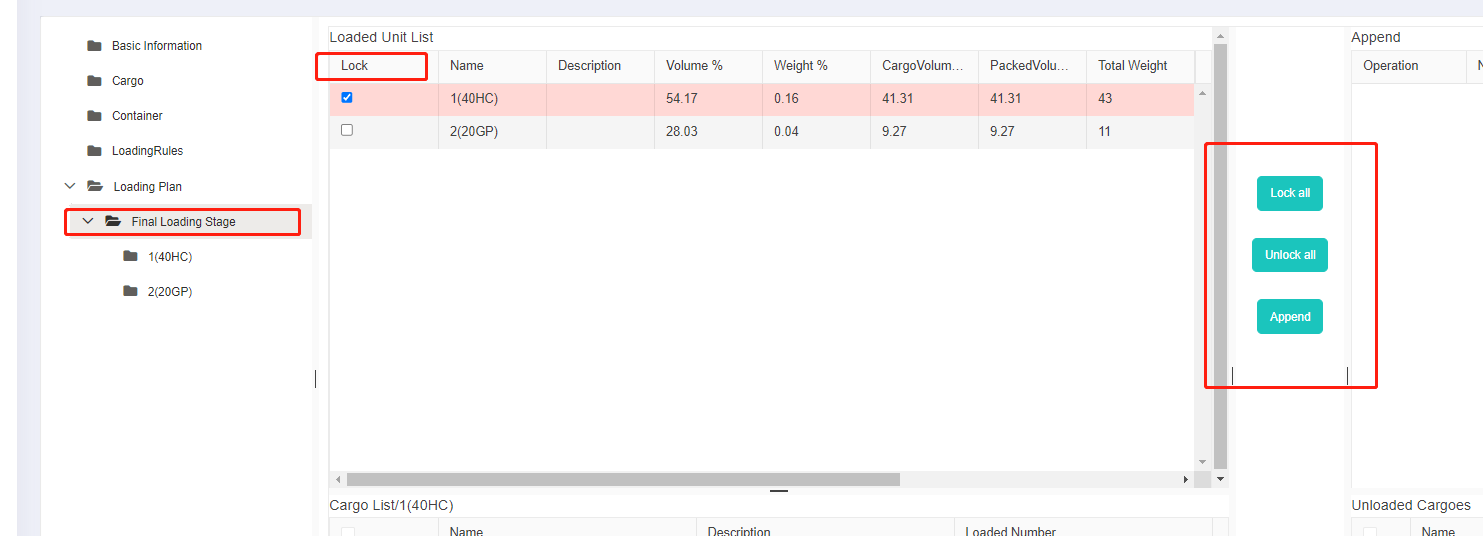

Compared with manual calculation, Loadmaster container loading software can calculate way more faster. For example, an accurate loading solution can come out in about 3-5 min as for those cargoes with simpler loading requirements while a bit longer at most for about 10 min as for cargoes of various kinds and with complex loading demands. (The calculating speed of Loadmaster container loading software is actually in seconds, however the manual edit to meet some special needs may take a bit longer.) In this way, working efficiency has been uplifted to a great extent. With the help of 3D diagram, we can see that some container has not been full of cargoes so we can recommend adding more cargoes to increase the container utilization rate so as to decrease the average cost of each cargo loaded in this container. Users can also lock certain containers and recalculate the remaining containers which have not met the loading requirements. There are six suites of algorithms. By different algorithm adjustment, you can get different loading results to choose. Sometimes you may find that the loading result is the same, which indicates that this result is the most optimal. In short, loading solutions offered by Loadmaster container loading software highly increase the container utilization rate under the condition that all loading requirements have been met.