Chongqing Zongshen General Power Machine Co., Ltd., established in August 2000, is one of the world’s largest manufacturers in general-purpose gasoline engine. It has cumulative sales of tens of millions of general machines around the world and is dedicated to the R&D, manufacture and sales of various general gasoline engines to meet customers’ demands, and provide professional after-sales services, General Power Machine Company also manufactures and sells generator units, water pumps, high-pressure washers and other general machines.

So what of LoadMaster load planning software has attracted General Power Machine Company? Let’s check it out!

As a large enterprise, Chongqing Zongshen General Power Machine Co. exports many kinds of products. Only one customer’s order can contain up to 30 kinds of cargoes. Under such circumstance, they need to take many factors into consideration while designing a load plan including if the load plan can meet all loading requirements, the convenience of on-site loading operation and the center of gravity of the container. Calculating such a load plan is completely beyond human brain’s capabilities. In this case, they can only estimate the quantity of containers needed and cannot get accurate loading details. Not to mention to guarantee that the center of gravity is within the range required by transportation authorities, which may result in the unnecessary fine cost. Sometimes in order to ensure that customers receive the cargoes in time and the center of gravity of the container can meet the requirement, they have to reduce the quantity of cargoes in the container which is easier to arrange the loading of each cargo, resulting in the problem of a low container utilization rate, which increases freight costs.

Four loaded containers.

Four loaded containers.

According to their feedback, the calculation of a container load plan is mainly divided into three steps:

- Determine the initial cargo details of the shipping order with the customer;

- Adjust the quantity of cargoes to achieve the highest container utilization rate;

- Calculate a final optimal load plan which can ensure the feasibility of on-site loading. And in this process, they usually confront the following difficulties:

What is the maximum quantity of cargoes that can be loaded in a container?

Does the center of gravity of the container coincide with the center of the container?

Are the same cargoes placed next to each other? Can the same cargoes in different orders be loaded in specified containers?

Can the loading sequence of cargoes to different destinations be set correspondingly?

Can the load plan be manually edited to meet some special loading requirements?

As tricky as these difficulties are, LoadMaster can solve all these problems and also successfully wins their attraction!

Chongqing Zongshen General Power Machine Co., Ltd. purchased LoadMaster software in 2020 and has benefited from it greatly in the past three years. Both the container utilization rate and work efficiency have been improved greatly. The freight cost has also been obviously reduced which has brought a great amount of profits to the company.

The advantages are as follows:

1.Convenience

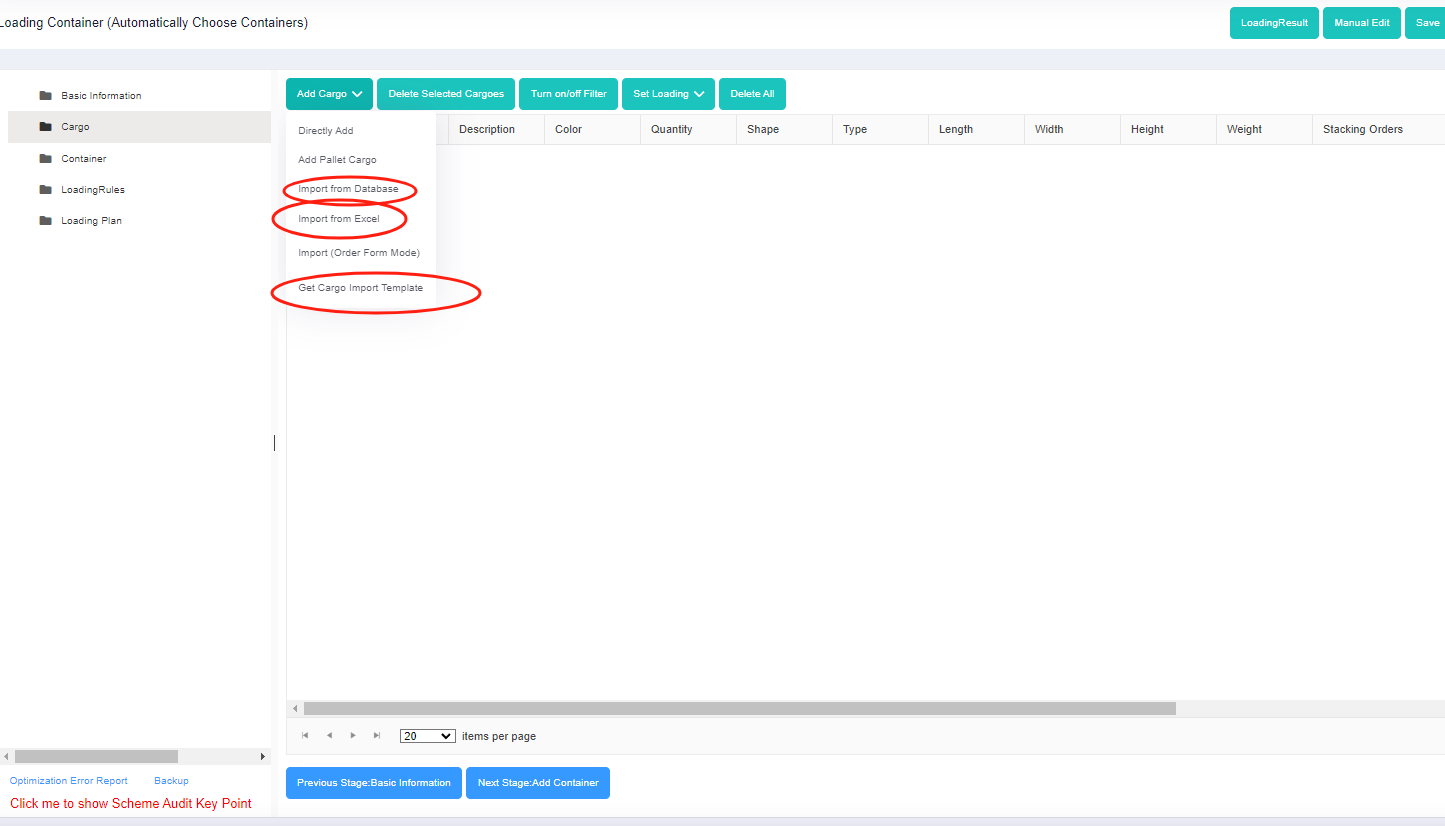

Users can input loads of cargo information in batches through Excel template and can set parameters directly in the template. The cargo database and container database can allow users to store the information of frequently used cargoes and containers in the software, avoiding the repetitive input of the same information of low efficiency.

Different cargo import ways.

Different cargo import ways.

All the load plans are kept in Task History which are easy to retrieve when needed.

2.100% meet all the loading requirements

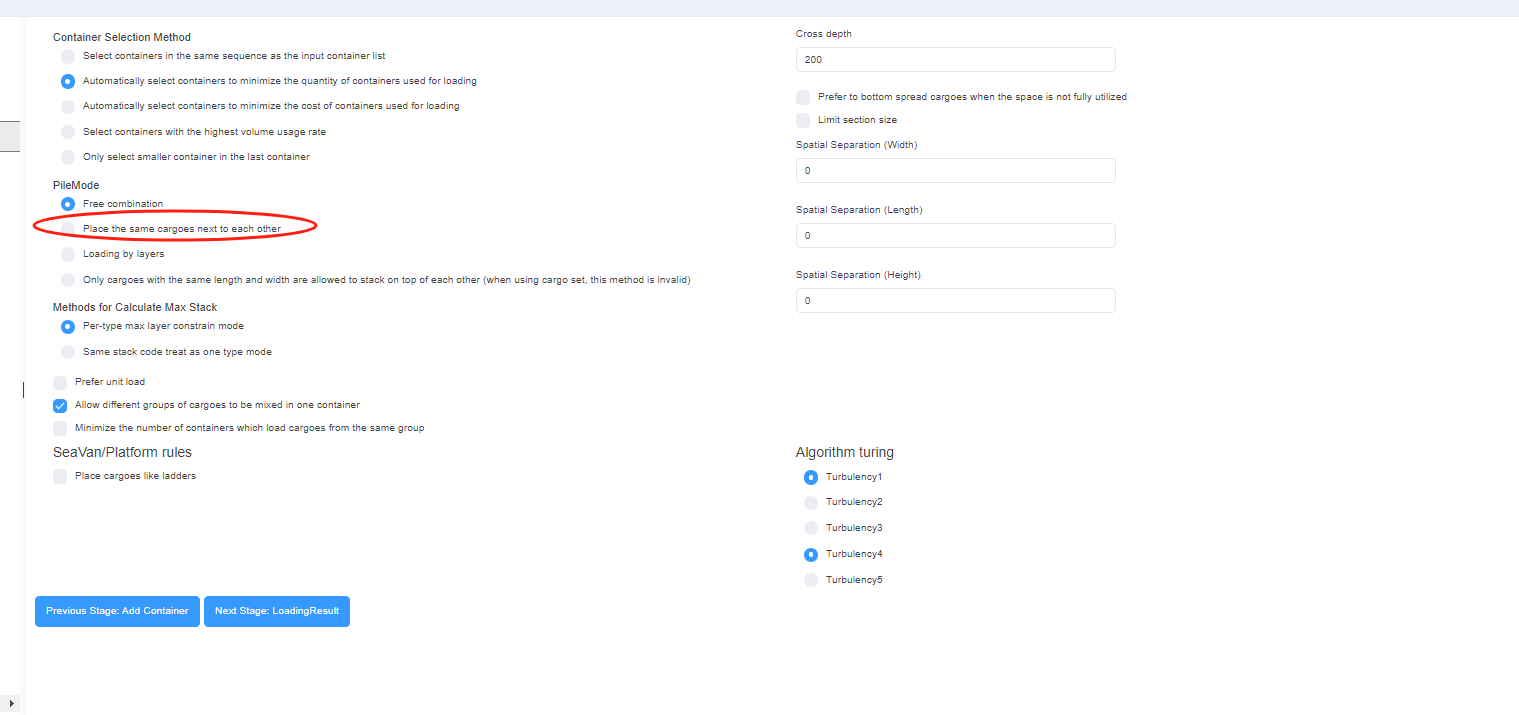

a. In the process of calculation, LoadMaster can realize the same cargoes are placed together and set different loading sequence according to different destinations.

Loading rule “Place the same cargoes next to each other.”

Loading rule “Place the same cargoes next to each other.”

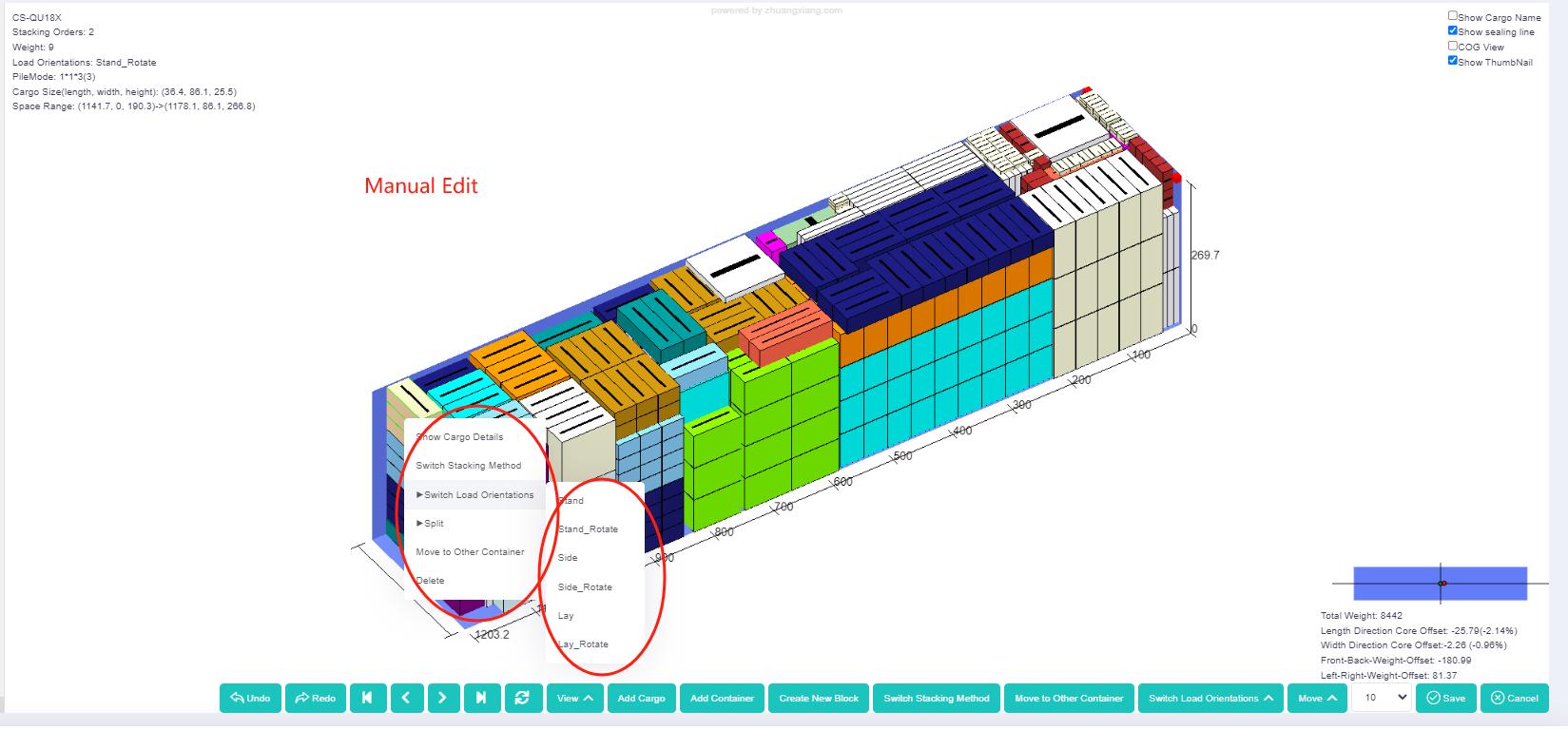

b. Users can adjust the loading of certain cargo by “Manual Edit” and can move cargoes between different containers, so as to meet some special loading requirements or the requirement for the center of gravity of the container.

3d picture of manual edit.

3d picture of manual edit.

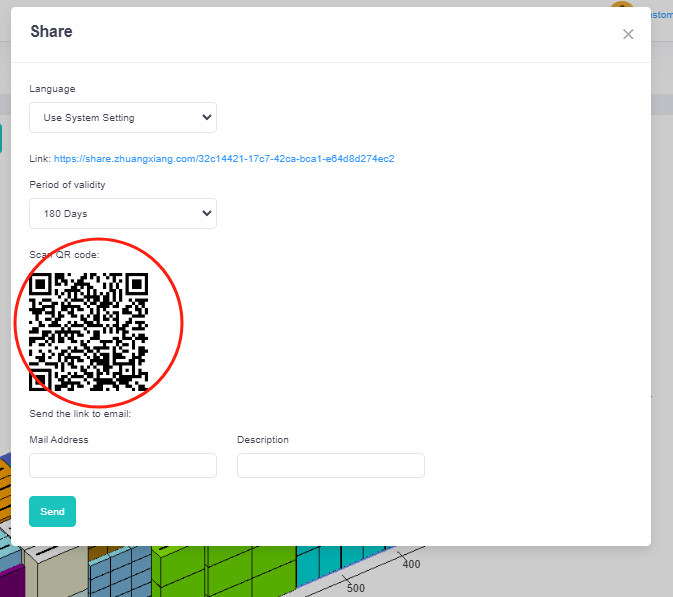

c. The 3D load plan can be shared to mobile platforms by scanning the QR code which can guide on-site loading anytime and anywhere.

QR code to share the load plan.

QR code to share the load plan.

d. LoadMaster load planning software also realizes combining the palletizing and containerizing together, offering optimal load plans that can tell users not only how to containerize but also how to palletize before loading cargoes into containers.