Fujitec Co., Ltd is a leader in the elevator manufacturing and installation industry, providing products and services in multiple fields such as home elevators, passenger elevators, and cargo elevators. Its products have been sold to many countries and regions around the world, including Europe, Asia, North America, South America, etc. Since 2014, it has partnered with LoadMaster cargo loading software for 9 years.

Why did they choose LoadMaster? Let’s check it out!

As a machinery manufacturing enterprise, their products are mainly elevator parts being loaded in the way of wooden boxes or just loaded as bulk cargoes. Due to the fact that the volumes and types of wooden boxes are different, the bulk cargoes are diversified, and some loading requirements are special, different cargoes cannot be stacked with each other, resulting in a time-consuming and laborious manual calculation. In this way, the working efficiency is quite low and the error rate is quite high, making the real loading almost impossible. What’s worse is that the whole shipping process and data can not be tracked which means it’s hard to operate standardized and transparent management at different steps.

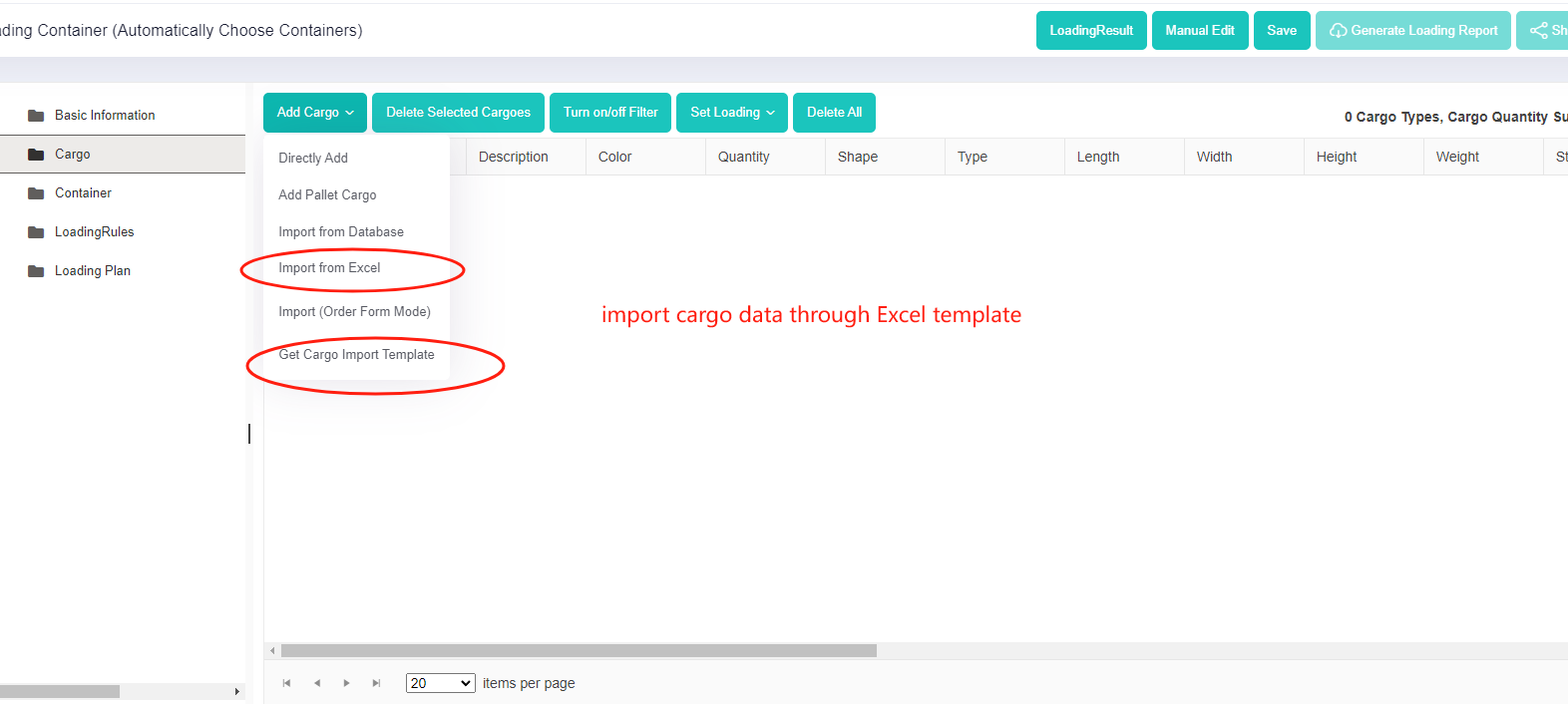

With the help of LoadMaster, loads of data can be imported into the software through Excel template and some loading requirements can be met by setting parameters and loading rules in the template, greatly improving our working efficiency.

Import cargo data through Excel template.

Import cargo data through Excel template.

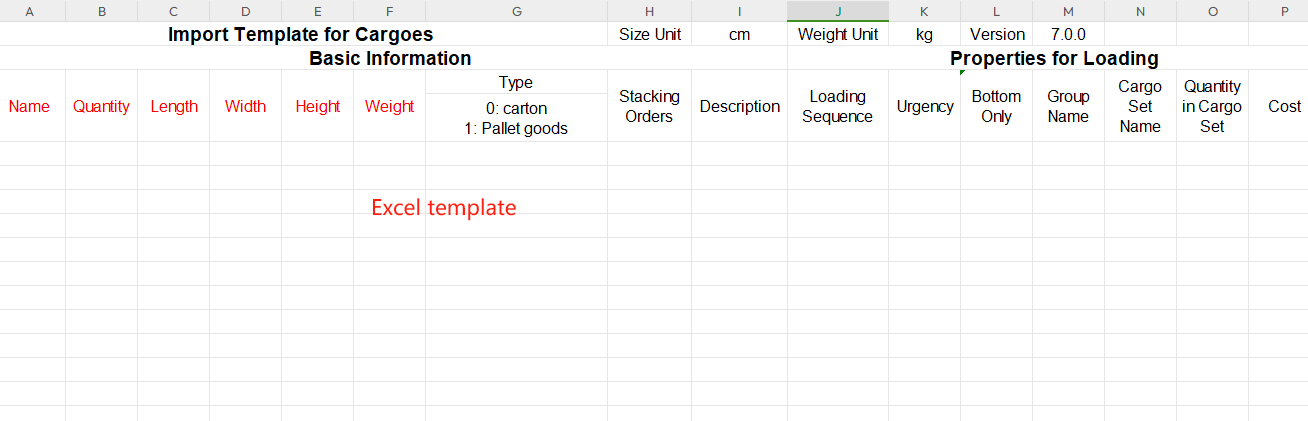

Excel import template for cargoes.

Excel import template for cargoes.

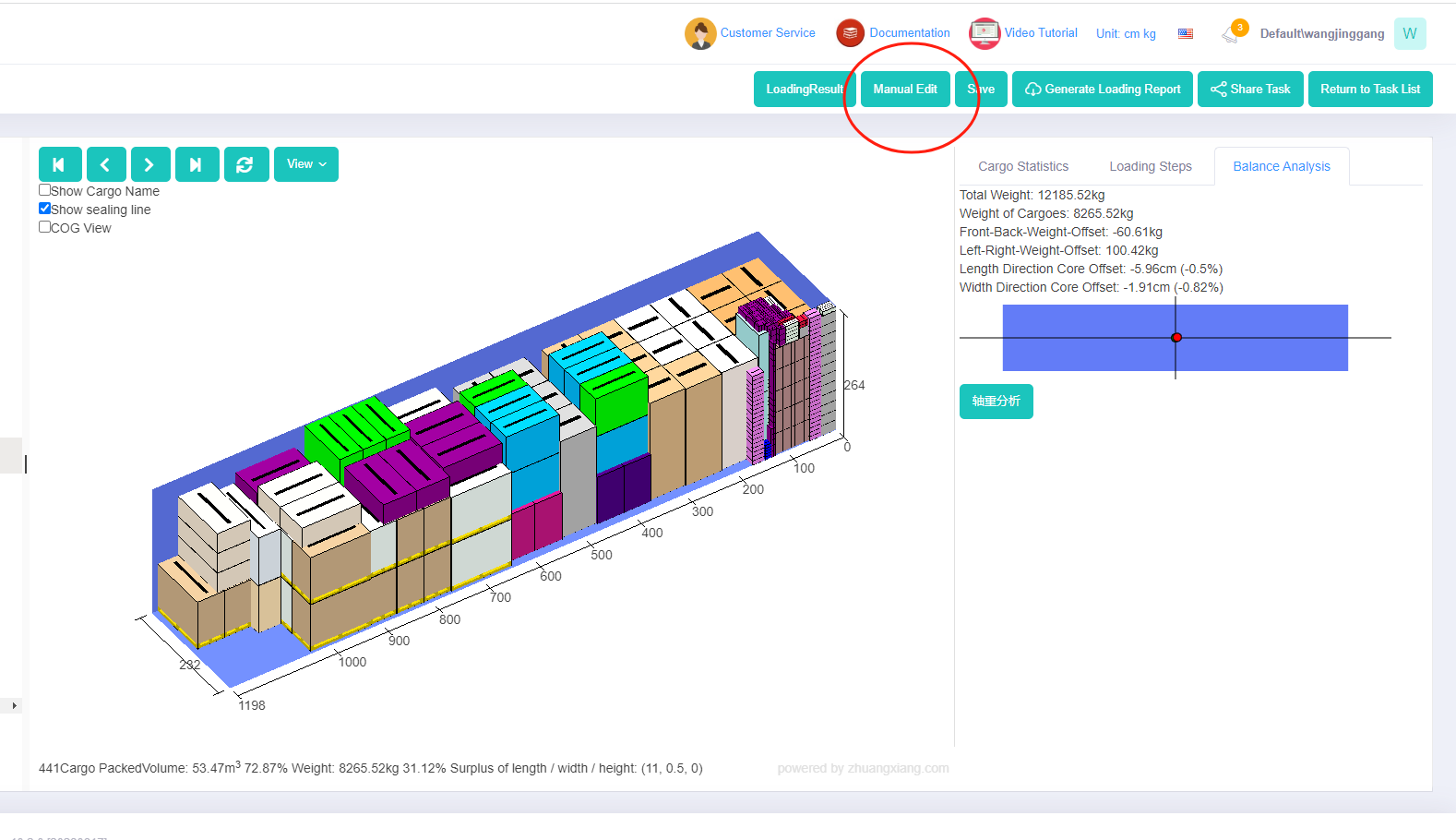

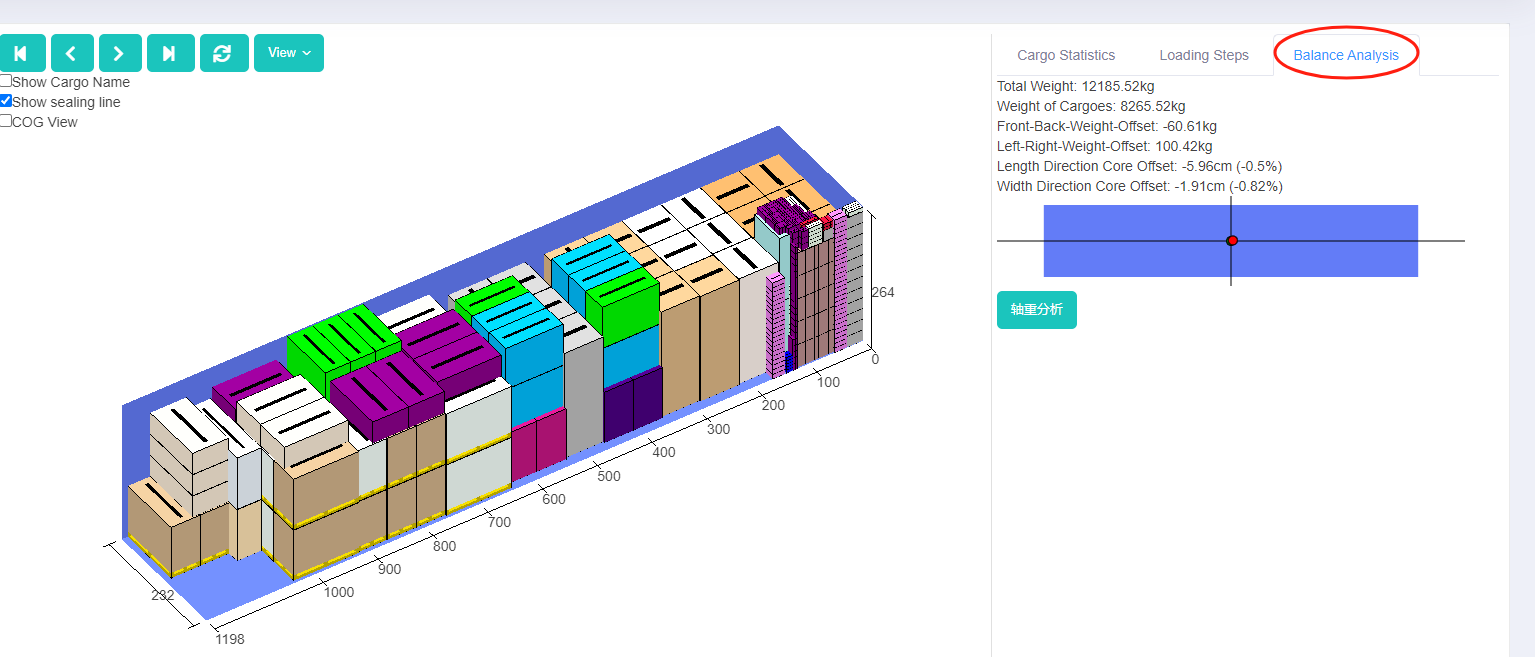

Manual edit function can meet some of their special loading requirements. The 3d diagram can clearly present how the cargoes are loaded in containers and some details can be adjusted through manual edit if necessary. What’s equally important is that the 3d diagram can also show if each container has kept balance, the container utilization rate and the volume utilization rate. The customer service of LoadMaster is very patient and timely with which we feel very satisfied.

Manual edit button.

Manual edit button.

Balance analysis on 3d load plan.

Balance analysis on 3d load plan.