What are the characteristics of the household appliance industry’s products, and what are their common loading requirements during the shipping process? Let’s take a look!

The household appliance industry encompasses a wide range of products, including televisions, washing machines, refrigerators, air conditioners, and more. Even within a single company, there may be multiple product lines, each maybe with multiple product types. This diversity results in a multitude of cargo specifications and significant differences in dimensions. Household appliance cargoes are often shipped in large quantities, leading to logistical challenges. As one of our clients pointed out, “With our business growing rapidly, daily shipments can reach hundreds of batches. Manually calculated load plan no longer meets our operational needs, and the logistics planning phase is under significant pressure.” Apart from varying specifications and dimensions, household appliance cargoes may also require careful consideration of weight distribution during loading to prevent product damage and minimize shipping losses. Additionally, the sequence of loading may be essential, especially when products are stored in different warehouses, and deliveries from various suppliers need to be coordinated.

The picture of different kinds of home appliances.

The picture of different kinds of home appliances.

Some household appliance products require palletizing before container loading. And sometimes it is needed to mix carton-packaged cargoes with those palletized. Some products may need to be disassembled into components for transport and then reassembled upon arrival, requiring proportional loading of component parts.

This is a picture of a pallet loaded with cargo.

This is a picture of a pallet loaded with cargo.

Addressing these complex loading requirements manually is challenging and impractical. This is where a powerful and versatile cargo loading software comes into play. LoadMaster is precisely such a saver, highly favored by many household appliance companies. With 16 years of experience in software R&D and customer service in the container loading field, LoadMaster covers 80% of well-known brands and has earned the admiration of prominent clients, including Haier, Hisense, Panasonic, Crown, Philips, TCL, Ariston, and more. Let’s explore the reasons why LoadMaster cargo loading software is beloved by so many clients!

A thumbs-up gesture.

A thumbs-up gesture.

LoadMaster software employs state-of-the-art loading optimization algorithms. According to customer feedback, using LoadMaster can increase space utilization rate by 5%-25%. This results in fitting more goods into a container, helping businesses achieve cost-effective logistics by maximizing space utilization.

A forklift is lifting cargo to load them into the container.

A forklift is lifting cargo to load them into the container.

LoadMaster cargo loading optimization software generate optimal load plans at high speeds, shortening the calculating time by 90% on average. Clear and intuitive 3D visual loading plans further enhance communication between departments.

Some people are loading cargo on site.

Some people are loading cargo on site.

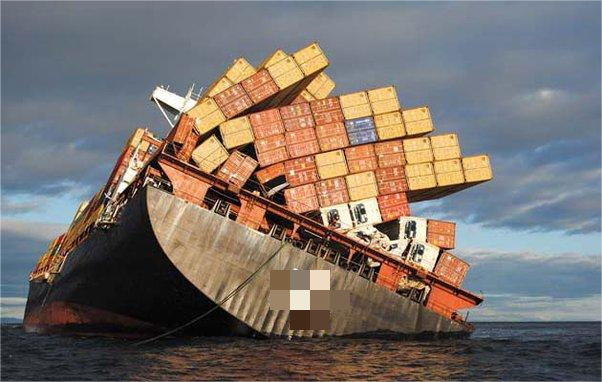

LoadMaster ensures accurate and safe loading, considering the varying weight-bearing capacities of cargoes when placed in different placement methods. This minimizes product damage during the shipping process.LoadMaster loading calculator also takes into account the center of gravity offset within containers. The software’s flexible manual editing features cater to personalized requirements. It also allows users to view 3D load plans on mobile devices, facilitating on-site loading.

This is a picture of a ship tilting over the sea.

This is a picture of a ship tilting over the sea.

LoadMaster’s two-step loading task type combines palletizing and containerizing into a single integrated optimization process. This enhances efficiency and helps businesses design intermediate packaging dimensions more effectively. LoadMaster is the only software in the world that offers the option slip sheets, further improving space utilization. One of our clients reported, “By switching from wooden pallets to paper slip sheets and using LoadMaster, we increased our space utilization. With these changes, the maximum stacking height in a 40HQ container went from 2 meters to 2.62 meters. This significantly improved space utilization from around 60% to 92%-93%, resulting in significant cost savings.”

LoadMaster is dedicated to delivering real benefits by solving container loading challenges for its clients. If you’d like to experience the powerful features and dedicated service of LoadMaster, you can try it for free for 30 days (full functionality without times limitations). The software also offers free remote demonstration of software operations.

Check how we can help home appliances industry at https://blog.loadmaster.biz/2023/11/02/40/