Are you from the furniture industry? Then you must know well about the features of products from this industry and their complex loading requirements. Let’s take a look!

1.The need to avoid cargo damage since some furniture products are sensitive to the pressure of weight.

2.Difference of packaging style for different products

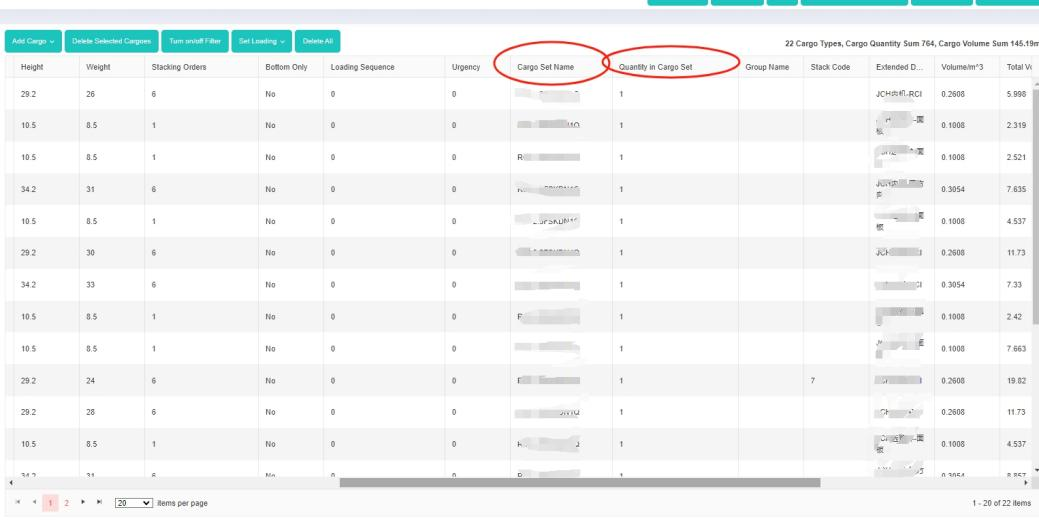

3.Some products would be disassembled into different parts and then shipped, so the quantity of different parts should be in a certain ratio.(eg. A set of office furniture is shipped in the form of 1 office table and 4 chairs. The ratio of table and chair is 1:4. Therefor the quantity of tables and chairs should be in the proportion of 1:4.)

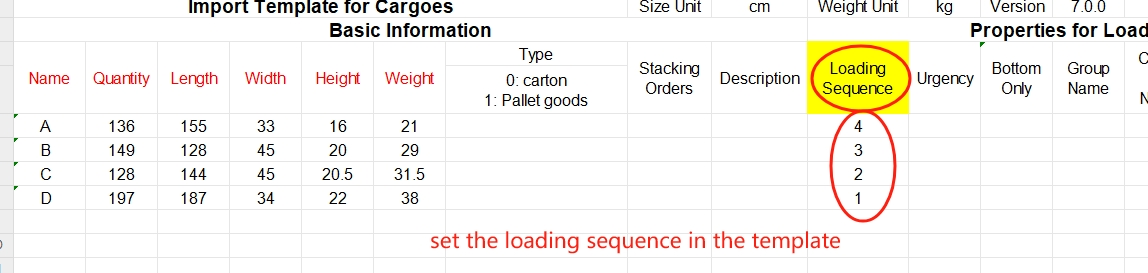

4.There is a sequence between different orders from different customers, requiring some orders of products need to be loaded earlier and some later.

5.Furniture products are gradually tailored to customers. ODM and OEM mode are gradually popular in the manufacturing of furniture products, thus having high demands for accurate loading.

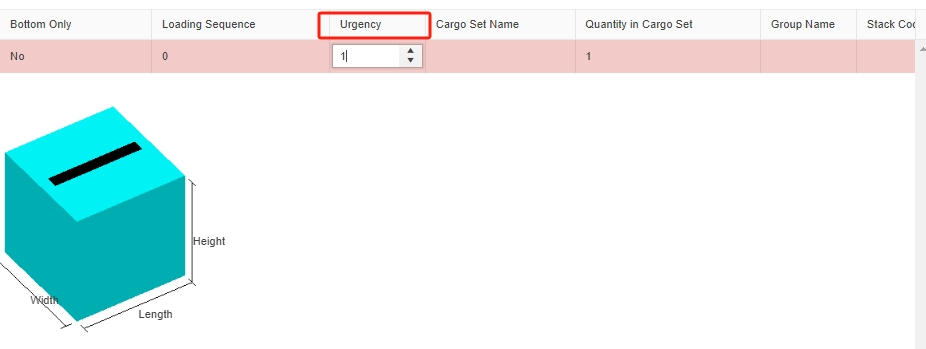

6.If the container is not full, some certain item can be regarded as not-urgent-to-load so their quantity depends on the rest remaining space in container.

The picture shows different kinds of furniture.

The picture shows different kinds of furniture.

How to meet all these complicated loading requirements? LoadMaster can give you the answer!

1.Avoid cargo damage as much as possible.

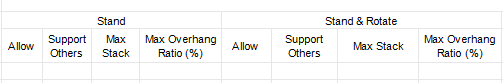

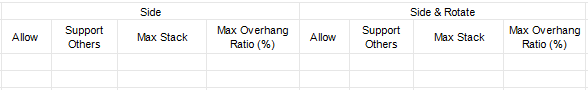

①Based on different load-bearing capacity, LoadMaster provides 6 placement methods for each item. Under different placement method, users can determine the maximum stacking layers and if other items can be placed on top of this item.

The “Stand” “Stand&Rotate” in the template.

The “Stand” “Stand&Rotate” in the template.

The “Side” “Side&Rotate” in the template.

The “Side” “Side&Rotate” in the template.

The “Lay” “Lay&Rotate” in the template.

The “Lay” “Lay&Rotate” in the template.

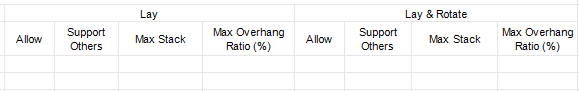

②Parameter “Stacking Orders” can be set to differentiate various items with different load-bearing capacities, defining the stacking relations of them. The value of the stacking orders indicates the loading capacity of the cargo. Cargoes with large stacking orders will be placed under cargoes with small stacking orders. The stacking orders is a relative value. The larger the value, the stronger the loading capacity, and it will be placed lower.

Stacking Orders column in the software.

Stacking Orders column in the software.

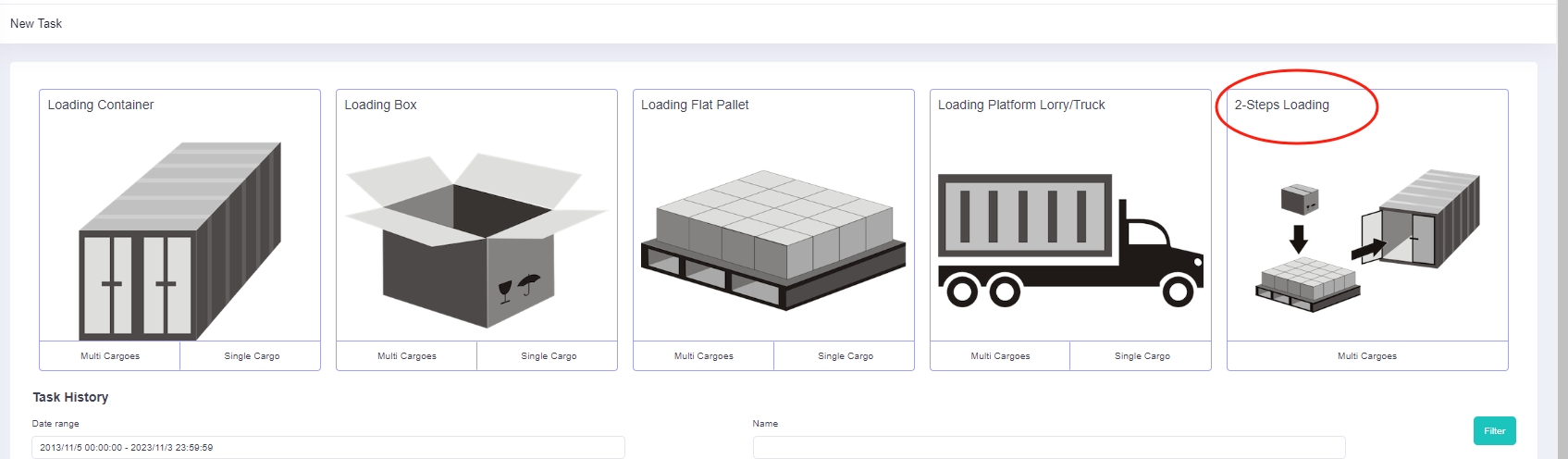

2.Some items are packaged in cartons then loaded into containers, others are packaged into cartons first, then on pallets and last loaded into containers. When it comes to mixing cartons and palletized cargoes, “Two steps loading” task type can integrate both palletization and containerization in one loading solution.

Two-steps loading task.

Two-steps loading task.

3d load plan of a two-steps loading task.

3d load plan of a two-steps loading task.

3.Set these parts as a same set and then define the quantity of them in one set. Parameter “Cargo Set Name” and “Quantity in Cargo Set” need to be defined by users.

“Cargo set name” and “Quantity in cargo set” columns in the software.

“Cargo set name” and “Quantity in cargo set” columns in the software.

4.When the loading demands involve specifying which cargoes are loaded first, and which cargoes are loaded later, users can set the Loading Sequence. The loading sequence is a relative value, the larger the value, the earlier the cargoes are loaded, and vice versa.

Set the loading sequence in the template.

Set the loading sequence in the template.

5.With accurate cargo data including dimension and reasonably setting loading parameters and rules, the accurate loading can be guaranteed based on the 3D loading guidance, avoiding the risk of reloading because the container cannot accommodate all the cargoes.

6.When the container is not full and a certain cargo which is not urgent to be loaded can be used to fill in the remaining space, users can set the parameter “Urgency” of this item as 1. And then where there is remaining space, there will be such item to be loaded, making the most use of each CM in the container.

Set the Urgency in the software.

Set the Urgency in the software.

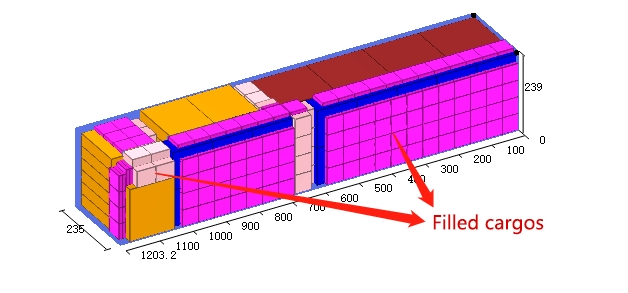

3d load plan that shows filled cargoes filling in the remaining room in a container.

3d load plan that shows filled cargoes filling in the remaining room in a container.

After configuring parameters according to loading requirements, LoadMaster can generate a 3D visual load plan with accompanying loading-step guide, which is convenient to help on-site loading and can help realize accurate and safe loading without the happening of mistaken cargo loading. According to LoadMaster’s tremendous clients’ feedback, the loading rate can be improved by around 10% and the work efficiency can be highly increased by over 85%, helping decrease shipping costs and increase profits for companies.

This is a picture that shows increasing money.

This is a picture that shows increasing money.

Check how we can help furniture industry at https://blog.loadmaster.biz/2023/11/03/41/