Products from the home appliance industry are usually in a great variety, resulting the big difference of size between products. And products in this industry are most high-value which has a high demand for safe loading and shipping. Additionally, the features of orders for this industry’s products ——“multiple varieties, multiple batches, and small batch sizes,” contribute to the complexity of container and truck load planning calculations. Below is a brief overview of common container loading rules for home appliance products, let’s take a look!

1.Different SKUs have varying maximum stacking layers. For instance, televisions can be stacked up to 3-5 layers at most. Haier, as a A large-scale company with significant business volume, has diverse product lines with varying sizes.

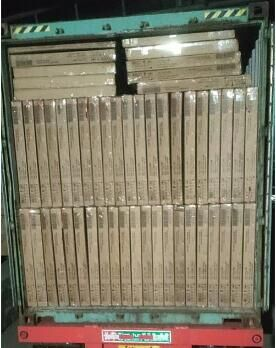

This picture shows cargo stacking for 3 layers in a container.

This picture shows cargo stacking for 3 layers in a container.

2.Different load-bearing capacities exist for the same SKU depending on different placement methods. For example, air conditioners are preferably placed upright and cannot have other items placed on top when laid sideways.

3.Heavy cargoes no pressing light ones: Due to varying product categories or packaging methods, consideration is needed during truck and container load planning to prevent cargo damage by not stacking heavy items over lighter ones or larger items over smaller ones. For instance, the outdoor unit of an air conditioner should not be stacked on the indoor unit or the control panel.

4.Complete Set Loading: During air conditioner transportation, they are usually packaged as indoor and outdoor units, requiring them to be loaded as complete sets in a certain ratio. Occasionally, there may be scenarios where different models of air conditioners are mixed in the same vehicle or container.

5.Loading Sequence: Sometimes, the loading sequence of goods needs consideration. For instance, when products are stored in different warehouses, it’s common to unload one warehouse before moving to the next. The sequence of delivery from different manufacturers also needs to be considered.

6.In the home appliance industry, many products require palletizing before being loaded into trucks or containers. Some scenarios involve a mix of loading cartons and palletized products in one container.

Before collaborating with LoadMaster, Haier previously had a container loading software, but due to the complexity of their export business needs, diverse product lines, and varying sizes that couldn’t entirely meet loading requirements, it caused significant frustration for users. Moreover, during the covid period, there has been a sharp increase in shipping costs, making it imperative to improve the loading efficiency.

After using LoadMaster, they found “LoadMaster software’s algorithm is very powerful and advanced, meeting their precise loading requirements, such as automatically avoiding corner castings, loading as sets, palletizing before containerizing, and simultaneously considering load-bearing capacity while palletizing and containerizing. These aspects are highly important. Additionally, the efficiency of container allocation has significantly improved. Scanning QR codes with mobile phones to view 3D load solutions is highly advanced and practical, providing a more intuitive experience.”

Haier not only just purchased LoadMaster, but also implemented a project by integrating LoadMaster with their order placing system, which served national distributors. After the successful integration, they will only allow an order to be placed when each truck’s loading rate reach 90% or more in each order. Then the cargoes would be directly shipped from production sites to distributors, saving the costs of transit storage. According to Mr. Yang from Haier, after the integration, LoadMaster helped them save $15k each day. What an amazing amount!

Do you have many different SKUs with various dimensions? Do your products have strict stacking constraints?

Check how we can help home appliances industry at https://blog.loadmaster.biz/2023/11/02/40/