Shanghai Volkswagen - Xiangyun Transport is a prominent entity in the transportation industry. Renowned for its versatility, the company offers an extensive range of transportation services. These encompass cargo logistics, warehousing solutions, and streamlined freight forwarding services tailored to meet clients’ specific requirements. The company boasts a large-scale operation that spans extensive networks, facilitating seamless transportation across regions.

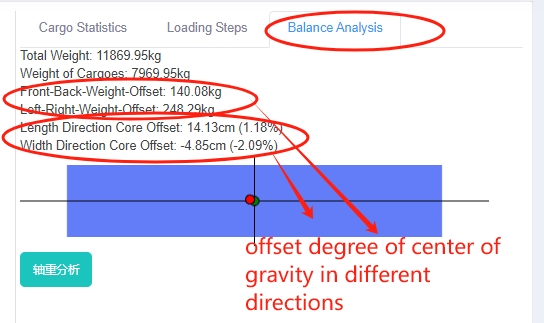

According to Mr. Shi from this company, during the loading of containers, it was observed that maintaining the cargo’s center of gravity was crucial. However, manually adjusting the container’s center of gravity was too hard for the work force and didn’t have a satisfying result. Therefore, the company wondered if there was a load planning optimization software to help simulate the scenario and manage the center of gravity.

After comparing several container loading simulation software options, they found that LoadMaster is simpler to operate and offers more user-friendly operations compared to others. Furthermore, LoadMaster’s load plan has a higher loading rate. Hence, the Shanghai Volkswagen - Xiangyun Transport company chose LoadMaster load planning optimization software.

Upon using this load planning simulation software, there was a significant improvement in container loading rate, work efficiency, and the rationality of the loading arrangement of various cargoes in containers:

- Container Loading Rate: Magnificently increased from 70% to 85%, which means 15% less shipping costs and 15% more profits!

- Simulation Time: Reduced from the original 1 hour to 45 minutes.

- Loading arrangement of cargo in container: The stacking of various SKUs within the container became more rational, effectively saving more space and enhancing the container space utilization.

- The center of gravity is well managed. With the help of LoadMaster’s clear balance analysis, we can tell if the container has kept the balance. If not, we can use manual edit, which is very convenient and intelligent to help adjust some cargo in the container to realize the balance.

Check how we can help auto parts industry at https://blog.loadmaster.biz/2023/10/31/38/