GAC Honda is a renowned participant in the automotive industry, offering a product lineup that includes sedans, SUVs, and electric vehicles. Their automobiles are distributed to dozens of countries and regions worldwide. Their export market spans across Asia, Europe, North America, the Middle East, and various other areas, catering to numerous countries and regions globally with their vehicles.

According to Mr. Xiao, their company is engaged in the export of automobile parts. They need to pack the parts into cartons and then place the cartons into standard export containers.In the loading process, they have following requirements which they found relying on human labor is hard to meet.

1.Cargoes should be stacked according to their different load-bearing capacities. Heavy cargoes cannot be placed above light ones.

2.Before using LoadMaster cargo loading optimization software, GAC Honda relies on the working staff manually drawing 2D loading diagrams to design how to load cargoes into containers. However, such diagram cannot meet their requirements. In the first place, it takes both a long time and a lot of efforts for people to design and draw the loading diagrams. In the second place, the loading sequence cannot be illustrated clearly on the 2D diagram. It’s hard to know which cargo should be loaded earlier and which ones later. In the third place, the 2D diagram cannot tell if the center of gravity is within a reasonable range. If the offset of center of gravity is too large, then that may cause the fine and reloading, which may result in the delay of cargo shipping and extension of the whole shipping process. The worst scenario is that the cargo cannot be delivered on time, and the customer satisfaction will be affected, which means the odds of losing customers.

Therefore as a company that focuses on sustainable progress in the long-run, GAC Honda stepped on the journey of asking for the help from cargo loading optimization software. And after testing and comparing both LoadMaster cargo loading optimization software and other competitors, they found that LoadMaster stood out and then decided to build a long-term cooperation with it.

Why and how could LoadMaster win their attention? Let’s check it out!

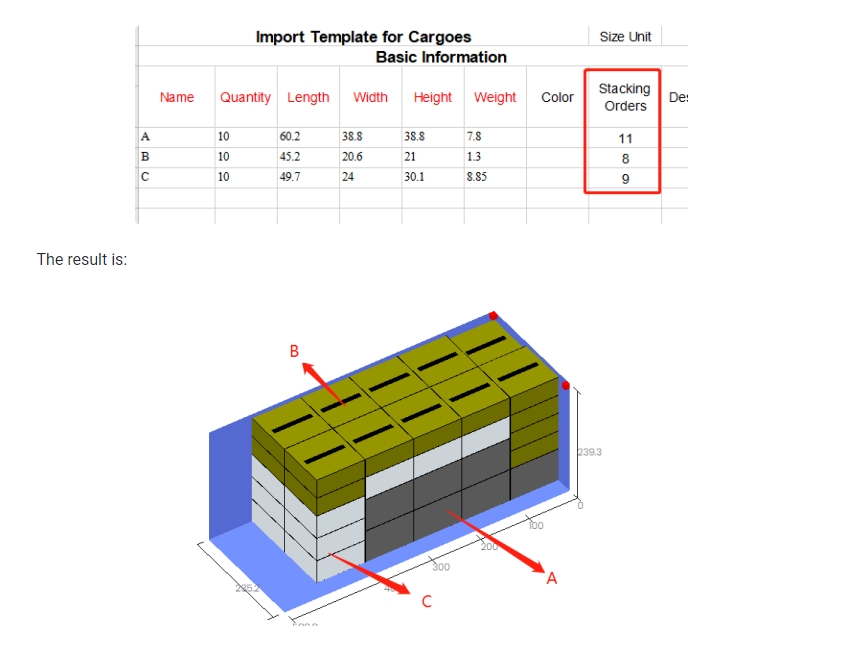

1.As to the requirement of stacking cargoes according to their load-bearing capacities, LoadMaster’s parameter “Stacking Orders” deals with this problem. Stacking Orders is a relative value which can show the difference of cargo’s load-bearing capacities. The larger the value, the stronger the load-bearing capacity.

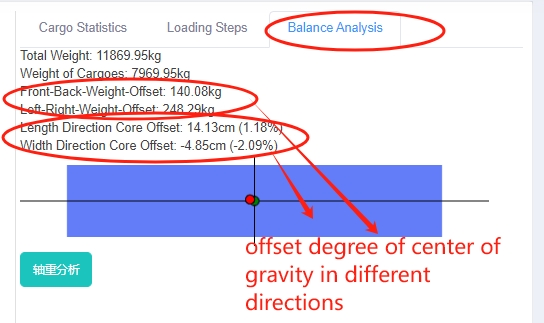

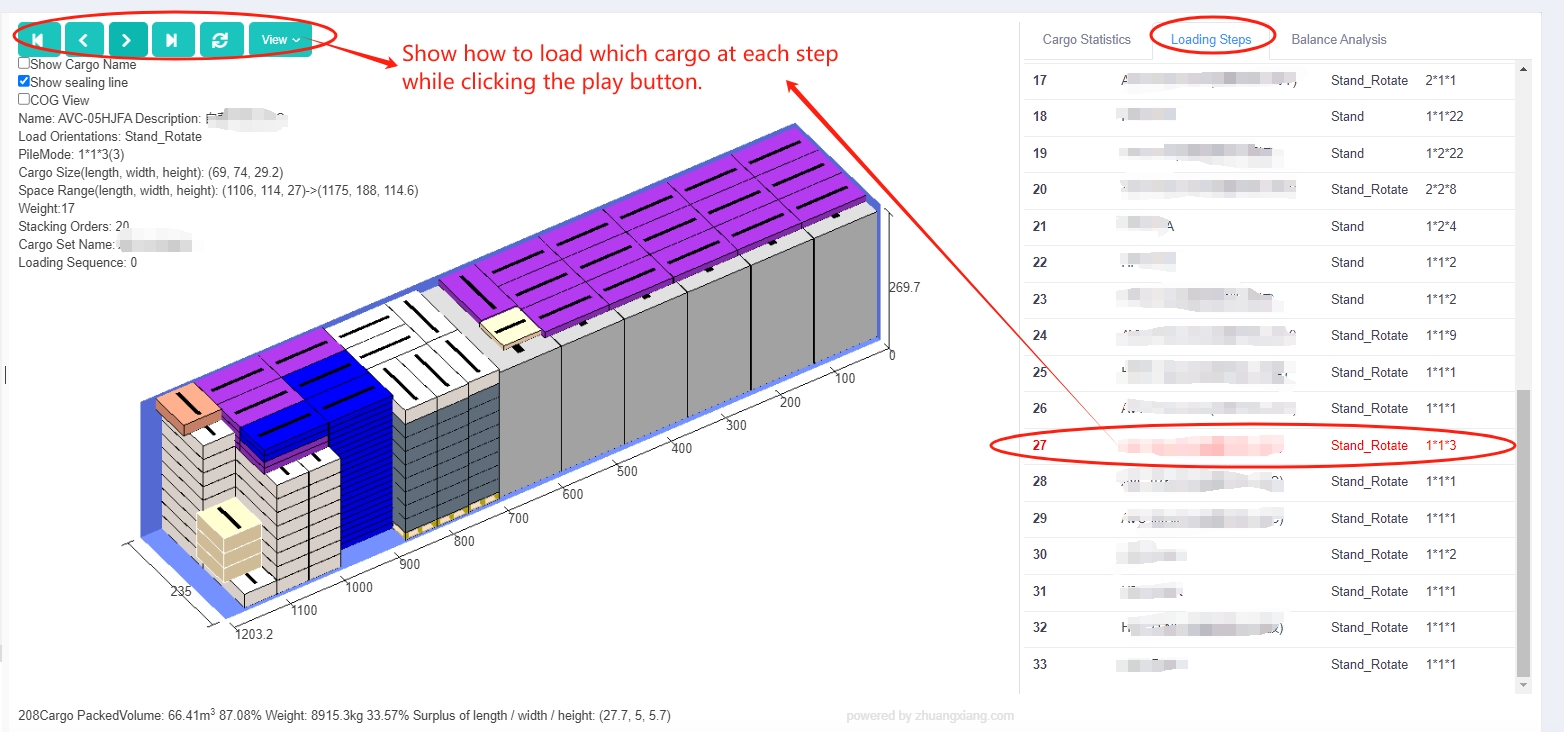

2.LoadMaster can quickly generate clear 3D container loading diagrams together with balance analysis and detailed loading steps guidance, which helps greatly improve the work efficiency.

With the lucid balance analysis, users can tell if the center of gravity is within a reasonable range. If not. They can adjust the the center of gravity through manual edit such as move the cargoes in the container, switch their stacking modes, etc.

With the distinct loading steps guidance, loading staff can know how to load cargoes into containers step by step, thus realizing the accurate loading and timely shipping. Customer satisfaction has also improved which is conducive to the sustainable growth of the company.

It has also improved the internal management, facilitate the transparent and standardized management of the whole shipping process, thus ensuring consistency and compliance of the loading operation files with loading process.

Do you have the same trouble while loading? Do you want to be saved from laborious calculations? Do you want to realize transparent and standardized management in load planning in logistics? Contact us to see how we can help!