Bouvrie has been conducted by a group of China’s Taiwan managers who has excellent skills in furniture field of 15-25 years. They are very professional in manufacturing small to medium size of wood furniture, such as occasional pieces, curio cabinet, dining table, office series, armoire. Bouvrie is the one of the best medium size furniture factory in Vietnam and most successful dedicated independent furniture factory.

According to Kate Wang from Bouvrie, they decided to purchase a cargo load planning software under such circumstances that “The increasing shipment volume often necessitates calculating the container loading capacity. Previously, this was done manually, leading to significant errors and frequently resulting in either underfilled or overfilled containers. Manual calculations were time-consuming, causing considerable inefficiency. Additionally, their clients have a high demand for the container loading capacity, and failure to meet the required CBM (cubic meters) can lead to fines which are unnecessary costs.”

When they had no clue about how to solve this tricky problem, they found LoadMaster cargo load planning software could not only meet their loading requirements but also brought them abundant real benefits. With the assistance of LoadMaster, they don’t need to rely on time-consuming manual calculation to generate load plans. The software-designed loading solutions can be got within seconds and are highly accurate. The container utilization rate has also been greatly improved, nowadays reaching as high as 89%, which helps increase the customer satisfaction.

According to them, the advantages of LoadMaster software are as follows:

1.Cargo data can be uploaded to the software in batches at one time, saving a large amount of time and avoiding the error brought by manual importing one cargo by one cargo;

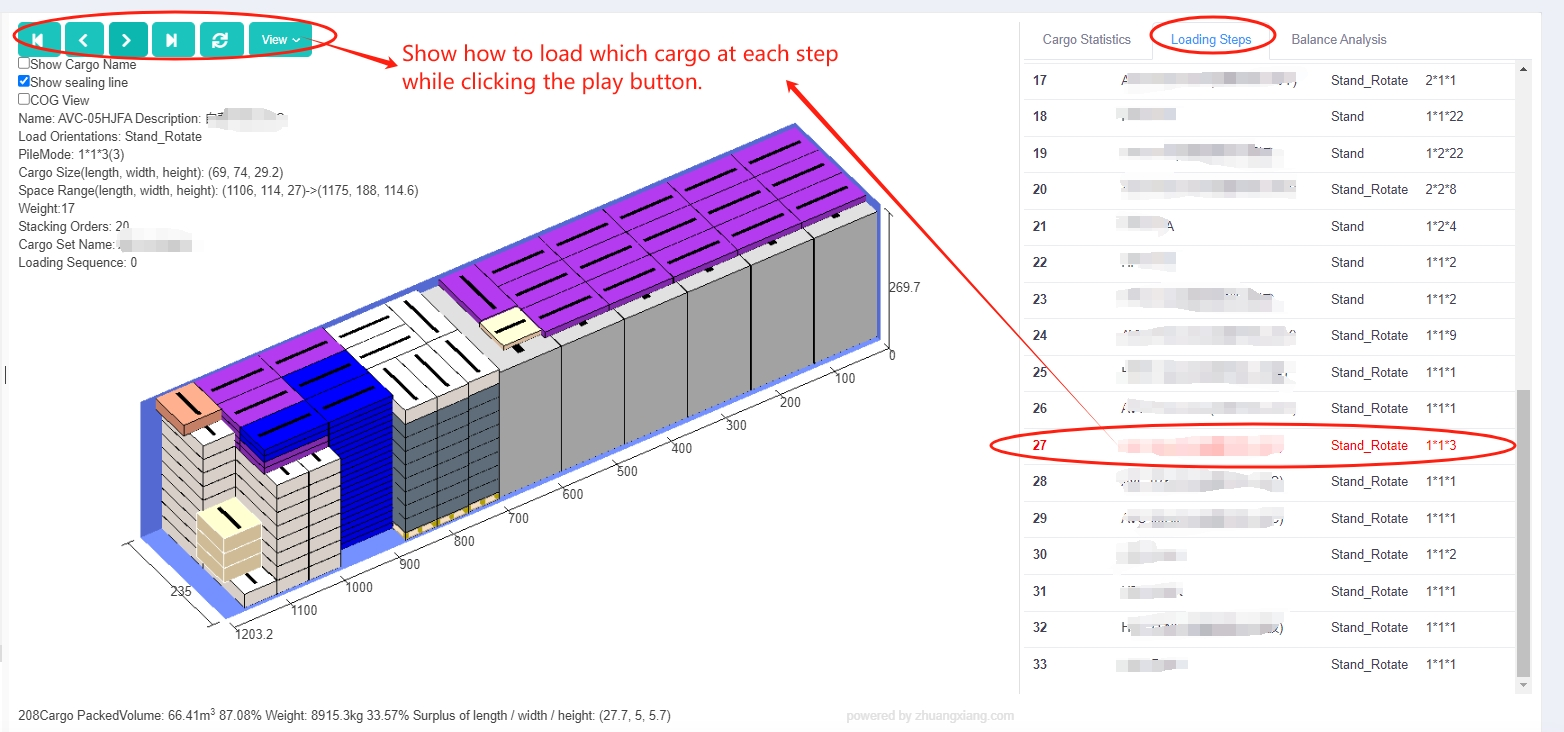

2.Clear 3D load plans can be shared with on-site loading staff to guide their on-site loading work;

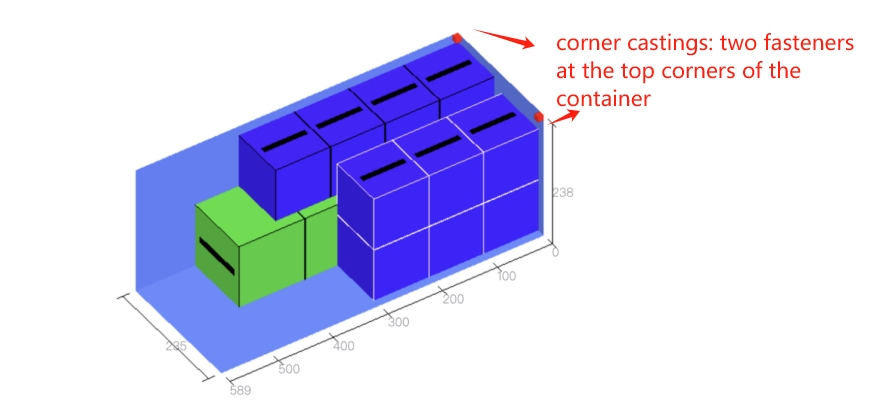

3.Easy to use but very powerful: LoadMaster has various functions and loading rules for users to define. It also has several parameters to simulate real on-site loading conditions such the corner castings (two fasteners on the top corners of the container which occupy some container space) size and reserved size in containers for the unavoidable distance between cargoes and the potential cargo expansion due to untimely shipping.

Check how we can help furniture industry at https://blog.loadmaster.biz/2023/11/03/41/