SUPCON is one of the leading product and technology, solution and service providers of process automation. SUPCON serves various process industries such as oil & gas, chemical, power, building material, pulp & paper, metallurgy, food & beverage, public utilities, etc.

Their products need to be first packaged into wooden boxes then loaded into containers.

Before working with LoadMaster load planning optimization software, SUPCON company primarily relies on manual estimation based on key large components for assessing the volume and specifications of wooden boxes. This method poses certain risks. Additionally, during the loading of wooden boxes for shipment, if the number of boxes is small, the loading and unloading personnel can handle it independently based on their experience. However, for exports requiring container loading or when the number of boxes is large, specialized guidance for loading is necessary, requiring pre-layout calculations.

Therefore, they hope to establish an in-house database of product dimensions, facilitating automatic calculation of the required number of items for packaging and compiling a packaging list. This will form the basis for intelligent logistics.

They also expect to achieve manageable and traceable shipping and packaging processes, accurately determine container specifications and reduce the kinds of wooden boxes, establish standardized loading, and create a loading database.

After using LoadMaster, they found the following advantages:

1.User-Friendly:

The interface is clean and user-friendly, requiring no specific training for familiarization and application of software functions.

2.Cargo Data Management:

Facilitates batch cargo data import, enabling convenient data sharing and transfer.

3.Container Management:

Standard containers within the industry have been added to the database, and custom sections can also be batch imported.

4.Loading Task Management:

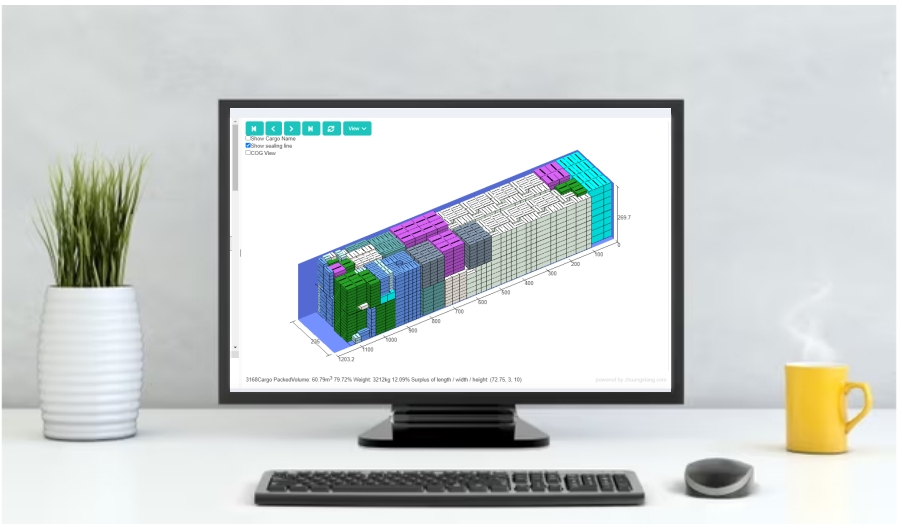

The exported Excel loading plan details the steps of container loading, providing clear and instructive guidance. The loading result list and intermediate packaging list are reflected in the exported plan, offering a clear view of space utilization within the containers. Based on calculated data from loading cases, the average utilization of wooden box space exceeds 80%. Additionally, it can calculate the loading space utilization, weight, volume, and other data for each paper box, wooden crate, and vehicle. This provides valuable raw data for future data analysis and size optimization.

LoadMasterhas helped improve the container loading utilization rate and shipping efficiency. The database establishment and loading calculations are remarkably efficient, yielding results better than manual calculations. Its application is straightforward, truly exemplifying a standard in the field of truck and container load planning optimization software.

Do you want to optimize your loading and shipping processes? Do you want to load and ship more efficiently?

Check how we can help home appliances industry at https://blog.loadmaster.biz/2023/11/02/40/