Have you ever encountered the following scenario? There is only one option for the stacking layers of items on one pallet which means the height of the palletized cargo is unchangeable. However, one-height pallets may cause that there is still much space not utilized. Wasted space results in unnecessary costs. How to avoid this and make full use of the container space?

LoadMaster cargo loading optimization software can generate different heights of palletized cargo to ship less air.

Let’s check it out with an exact example.

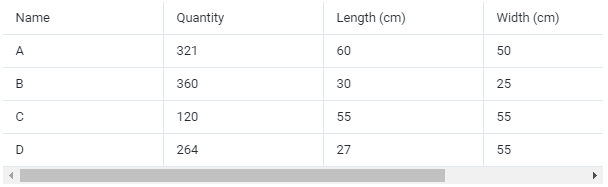

Cargo data:

Loading requirements:

- The items cannot be placed with the length vertical to the ground.

- Calculate how the items are placed on pallets and then loaded into the container type 40GP. The pallet is the Asian general flat pallet 1100mm×1100mm.

- The items should be packed into two pallets in containers. The maximum height of the cargo on the pallets is not limited.

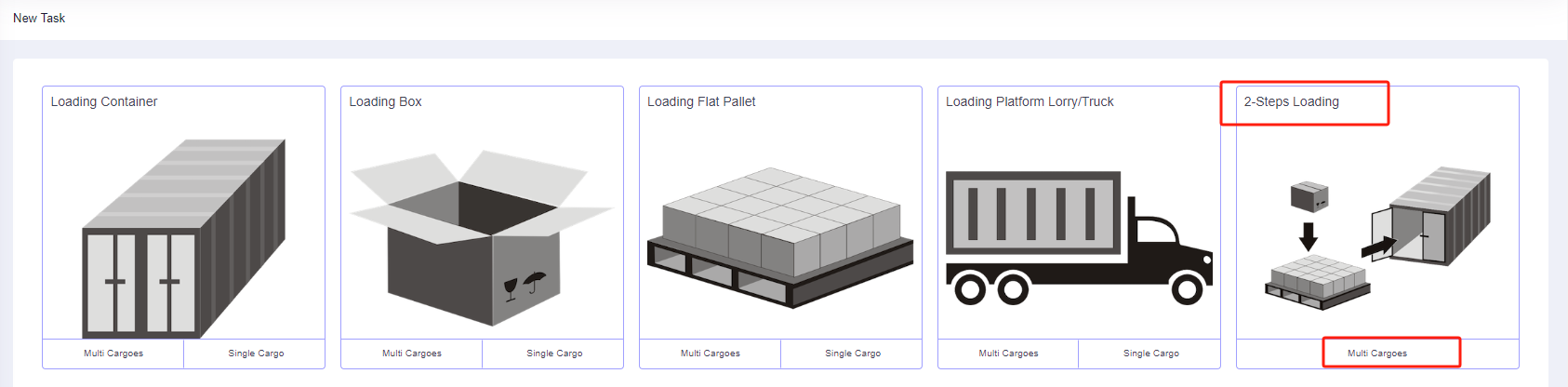

According to the current loading requirements, the container loading plan type [2-Steps Loading] should be selected.

Fill in the [Basic Information]. Then start to design the load plan.

Step 1: Click [Cargo] on the left to enter the cargo interface. For there are lots of cargo types, you should add them in batches by [Add Cargo>Import From Excel]. Firstly, click [Add Cargo>Get Excel Template] to download the Excel template and save it to a certain location in your computer.

Secondly, fill in the template with the cargo data.

①Copy the name, quantity, length, width, height, and weight (gross weight of a single carton) of the items into the template. Pay attention to the matching of the units.

②Then define the load orientations of the items. For it is required that cargoes cannot be placed with the length vertical to the ground, that is “lay” and “lay & rotate” are not allowed, you should fill in the “allowed” Columns of “lay” and “lay & rotate” with “0”. “0” means such placement of orientation is not allowed, leaving it blank or “1” means allowed.

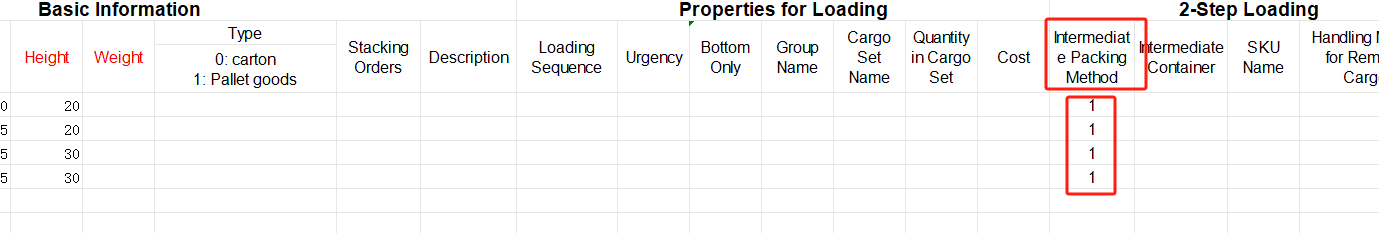

③Define the properties for loading. For the items are required to be palletized first and then loaded into the container, the “Intermediate Packing Method” of the items is set to “1”. “0” or blank means that the items are directly loaded into the container; “1” means that the items are free to choose the appropriate pallet/carton; “2” means that the items are loaded with the designated intermediate packaging.

For there are no other requirements, leave other loading rules as default.

Thirdly, return to the [Cargo] interface, click [Add Cargo>Import From Excel], choose the template you have finished, and open it. Then the cargo information will be imported to the software.

Step 2: Click on [Container] on the left to enter the [Container] interface. Add frequently used container types to the load plan and then the container loading software can select the most appropriate and cost-effective container. Edit the corner castings size and reserved size of the container, the size of the corner castings is 101010cm.

Since this load plan involves pallet loading, the height reserved size should be set as 10cm in order to facilitate forklift operations. In this way, the 10cm of container corner castings are also deducted, therefore the size of corner castings does not need to be set.

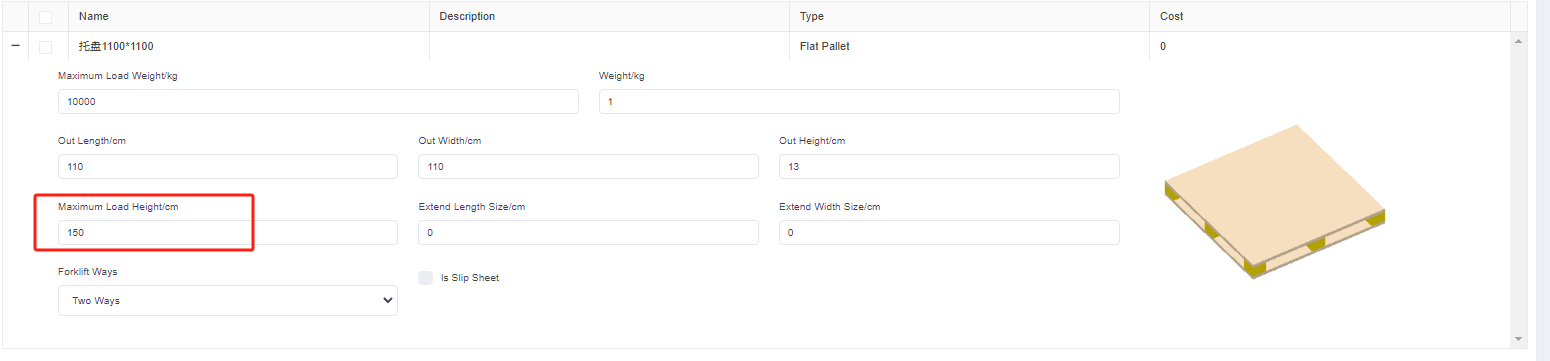

Step 3: Click on [Intermediate Container] on the left to add pallets. For it is required to use the Asian universal flat pallet 11001100, add it from the database. Click [Import from Database], check the pallet 11001100 in the pop-up box. Then define the [maximum load height] of the pallet. For the user requires the items to be packed into 2 pallets in container height, therefore the height of the items on a pallet is not limited. The maximum load height of the items on a pallet can be set to a value larger than half the height of the container. The value can be adjusted after checking the loading effect respectively. It is set to 150cm in this case.

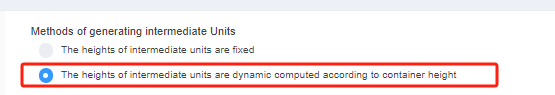

Step 4: Click [Loading Rules] on the left to enter the [Loading Rules] page. Since it is required that the items can be loaded in high and low pallets in order to make full use of the space. Therefore the [Methods of generating intermediate Units] is selected as [The heights of intermediate units are dynamic computed according to container height].

Step 5: Click [Intermediate Loading Rules] on the left to define the loading rules when the items are palletized. For there is no other special loading requirements, leave them as default.

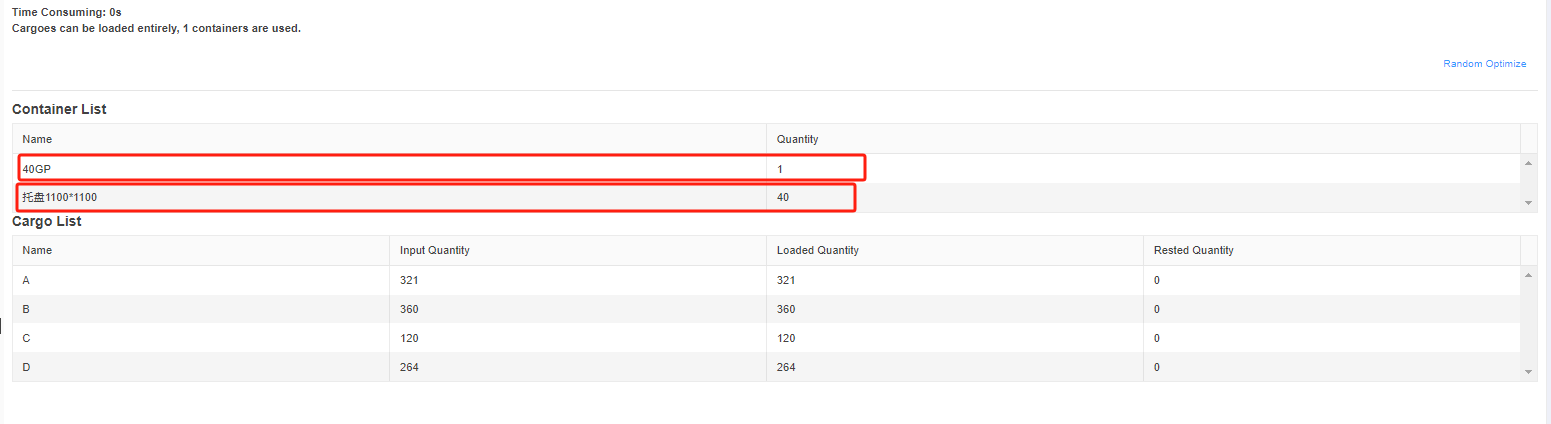

Finally, click [Loading Result] above or click [Loading Plan] on the left to calculate. With the advanced container loading optimization algorithm, the container loading plan is finished within 1 second. In the container list on the left, you can see that this batch of items used 40 1100*1100 pallets, and one 40GP. On the right side of the diagram are cargo statistics, loading steps and balance analysis of the current container. According to the 3D diagram, it can be seen that the items are loaded into different heights of pallets, which fully meets the loading requirements.

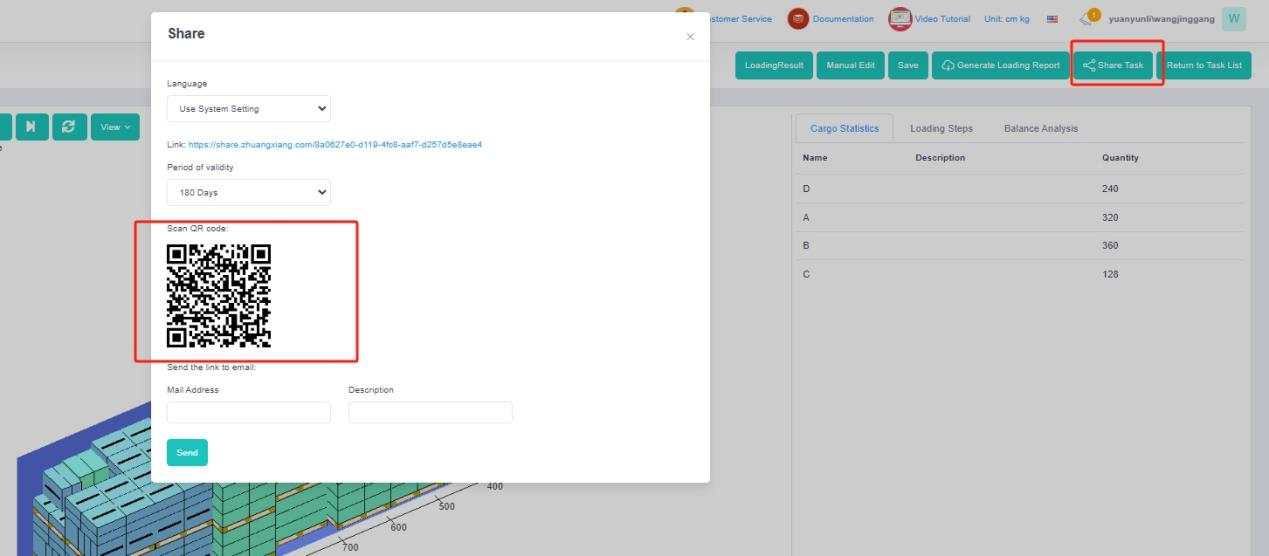

After the loading solution is completed, you can use your mobile phone to guide the on-site loading and download the loading report to make the packing list for customs declaration.