Is that possible that a cargo loading optimization software can realize loading the same kind of items on one pallet as much as possible? The answer is Yes, LoadMaster can help you do that!

When the goods are palletized first and then loaded into the container, it is required to generate unit-load pallets as much as possible. How to define such requirement in LoadMaster?

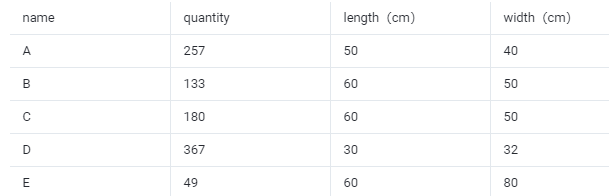

Cargo data:

Loading requirements:

- The goods can only be placed as the height is vertical to the ground.

- Calculate how the goods are palletized and then loaded into a 40GP.

- When the goods are palletized, unitload pallets are generated first, and then the mixed pallets.

- There are two types of pallets: 1200×1000mm, 1200×800mm. The pallet height is 10cm, and the max load height is 1.2m (including the height of the pallet itself).

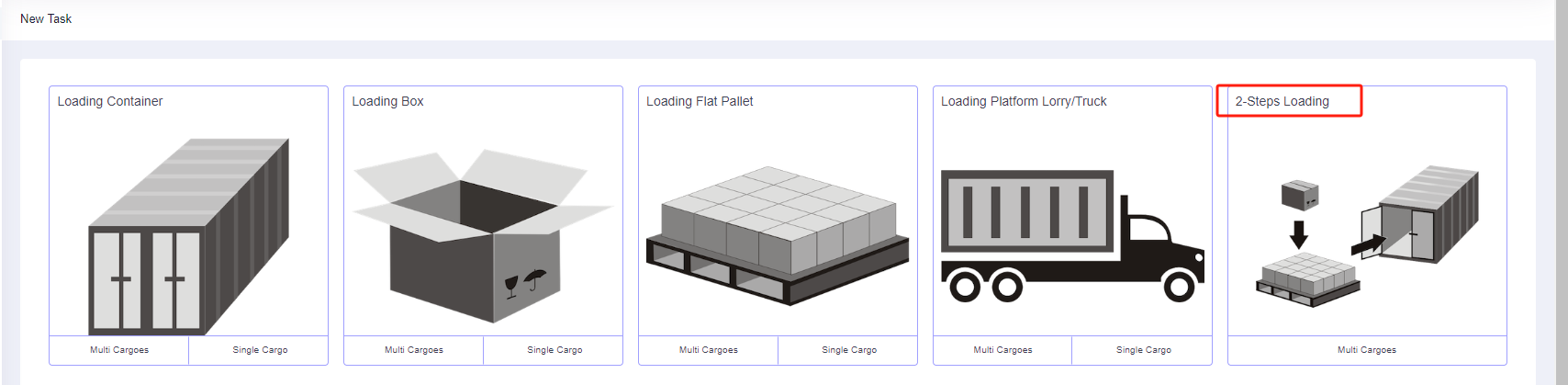

According to the current loading requirements, the task type [2-Steps Loading] should be selected.

Fill in the basic information for later check.

Next, start to designing the container loading plan:

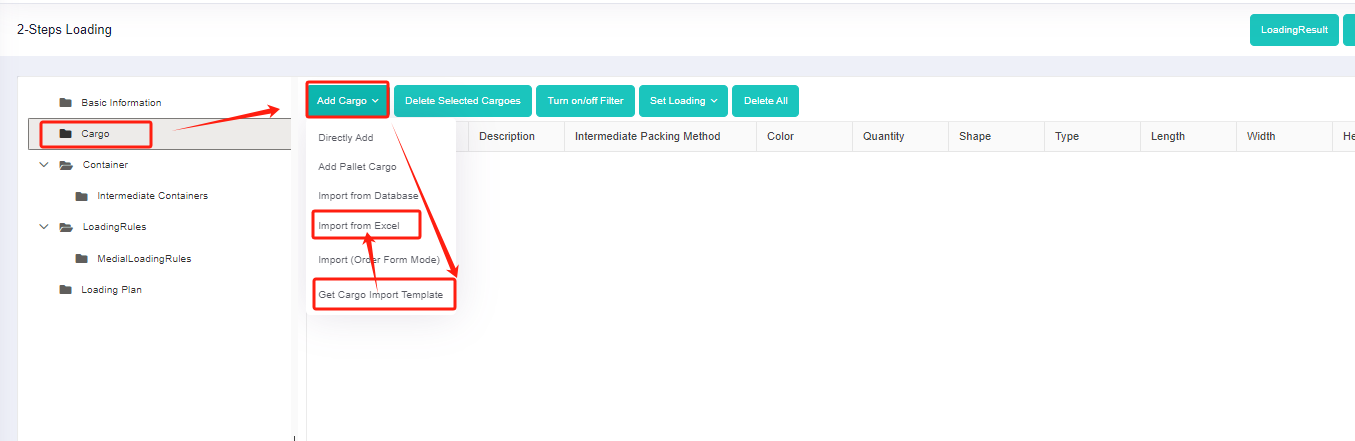

Step 1: Click [Cargo] on the left to enter the cargo interface. For there are various cargo types, add them in batches by [Add Cargo>Import From Excel]. Firstly, click [Add Cargo>Get Excel Template] to download the Excel template and save it to a certain location in your computer.

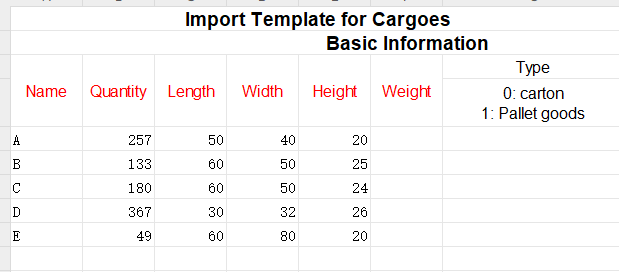

Secondly, fill in the template with the cargo data and loading requirements.

①Copy the name, quantity, length, width, height, and weight (gross weight of a single box) of the goods into the template, which are required items. Pay attention to the matching of the units.

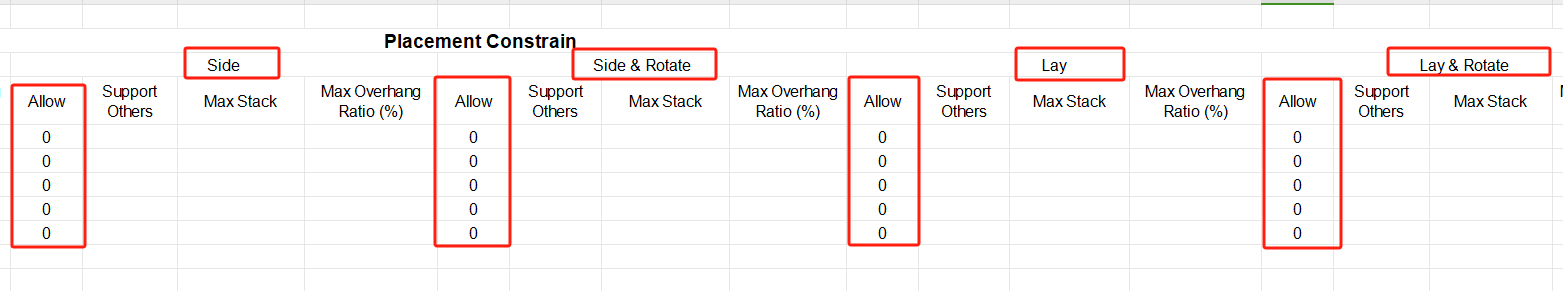

②Then define the placement methods of the cargo. For it is required that cargoes can only be placed with the height vertical to the ground, that is only “stand” and “stand & rotate” are allowed. Fill in the Column of other placement methods with “0”. “0” means not allowed such load orientation, leave it blank or “1” means allowed.

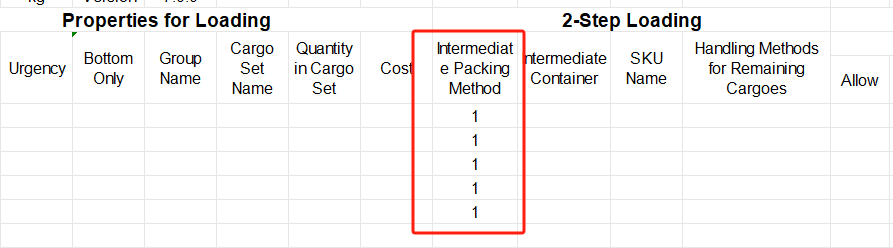

③Define the properties for loading. For the goods are required to be palletized first and then loaded into the container, the “Intermediate Packing Method” of the goods is set to “1”. “0” or blank means that the goods are directly loaded into the container; “1” means that the goods are free to choose the appropriate pallet/carton; “2” means that the goods are loaded with the designated intermediate packaging.

For there are no other requirements, leave other loading rules as the default.

Thirdly, return to the [Cargo] page, click [Add Cargo>Import From Excel], choose the template in the dialog box, and open it. Then the cargo information will be imported to the container and truck loading software.

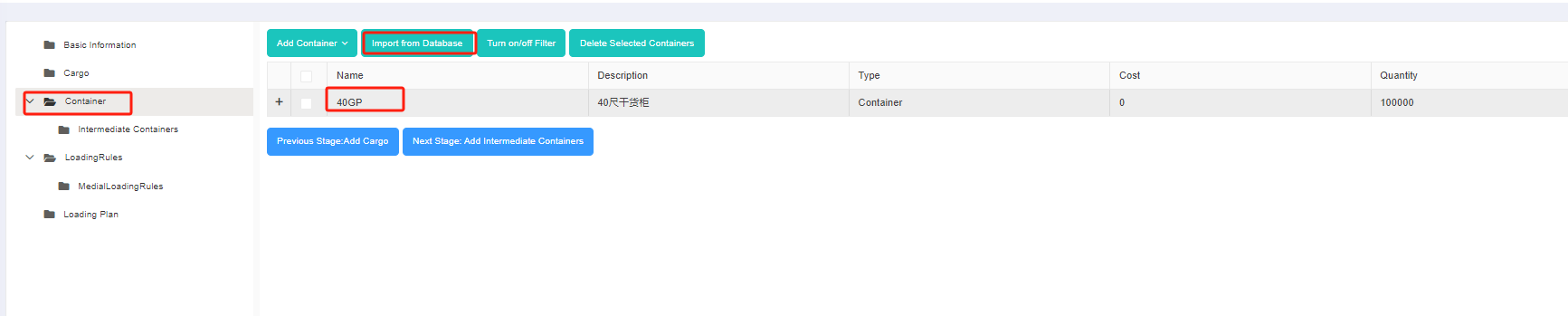

Step 2: Click the [Container] on the left to add a container. For this batch of items will be loaded with 40GP, you only need to add 40GP into the container loading calculator. Click [Import from Database], check 40GP in the pop-up box, and click [Add].

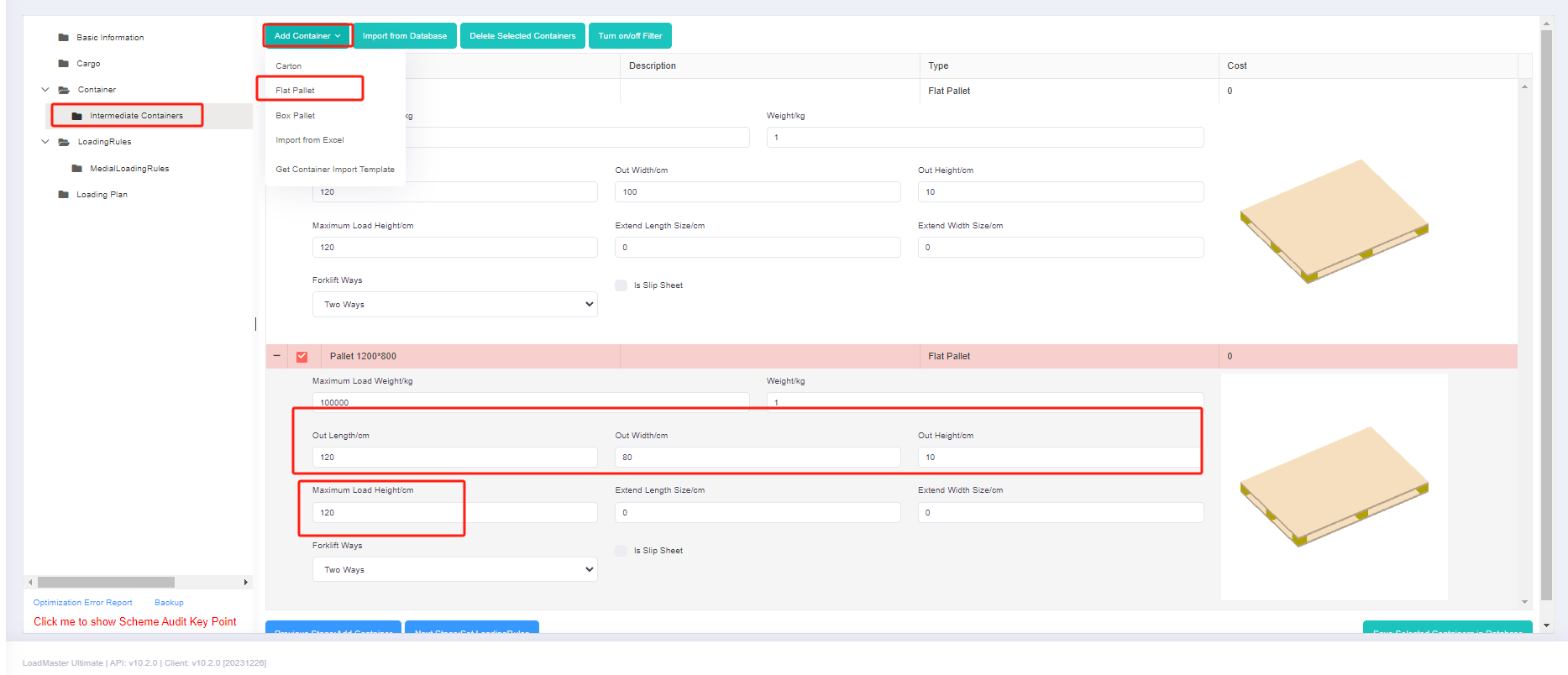

Step 3: Click [Intermediate Container] on the left to add a pallet. Click the [flat pallet] under [Add Container], and then edit the name (for example, “pallet 1200×1000”). The size of the pallet is 120×100×10cm, and the “maximum load height” is 120cm. In the same way, add the second pallet 1200*800.

Step 4: Click [Loading Rules] on the left to enter the [Loading Rules] page. For there are no special loading requirements, leave them as default.

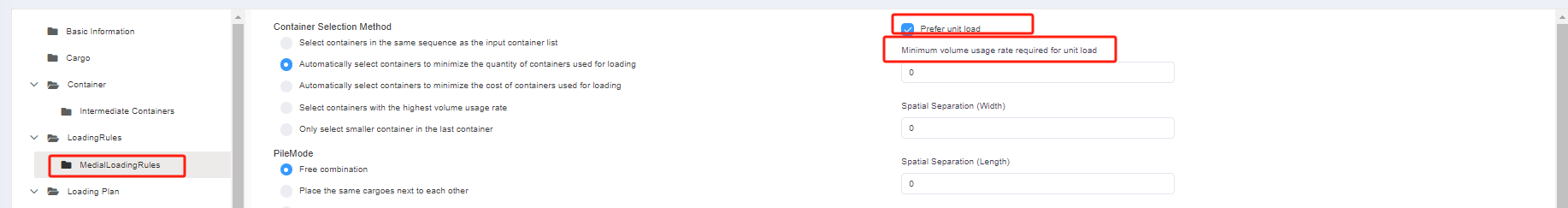

Step 5: Click [Intermediate Loading Rules] on the left to define the loading rules when the goods are palletized. For it is required to prioritizing loading the same cargo on one pallet , check [Prefer unit load], and set [Minimum volume usage rate required for unit load].

Finally, click [Loading Result] above or click [Loading Plan] on the left to calculate. And within seconds, the optimal container loading plan can be generated. On the right side of the 3D loading diagram are cargo statistics, loading steps and balance analysis of the current container.

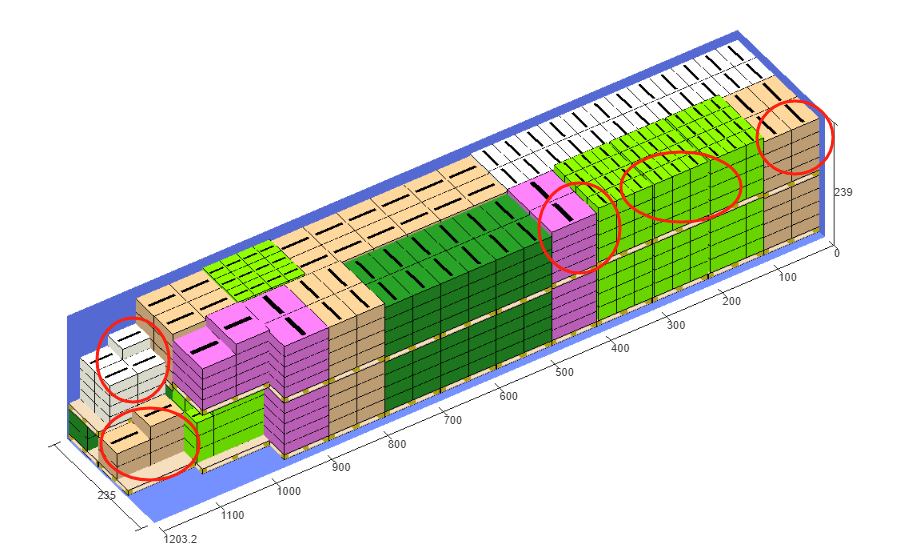

According to the 3D diagram, we can see that the same kind of cargoes are loaded on the same pallet, and the rest whose quantity is not enough to fill in a pallet are mixed with other kinds, which fully meets the loading requirements.

If there are too many mixed pallets, you can go back to the [Intermediate Loading Rules] interface, and adjust the [Minimum volume usage rate required for unit load] to be appropriately lower.

You can share the 3D container loading solution to mobile phones to guide the on-site loading and download the loading report to make the packing list for customs declaration.