Has this ever happened to you? When using a cargo load planning software to calculate container loading plans, for example, one shipment needs some containers such as 40HQ, 40GP, 20GP to load all the cargoes. But in the last container, there are only a few pieces of cargo left. Is there any possibility that these pieces of cargo can be loaded into the former several containers in some way? LoadMaster 3D cargo loading calculator’s cross depth may help, let’s see!

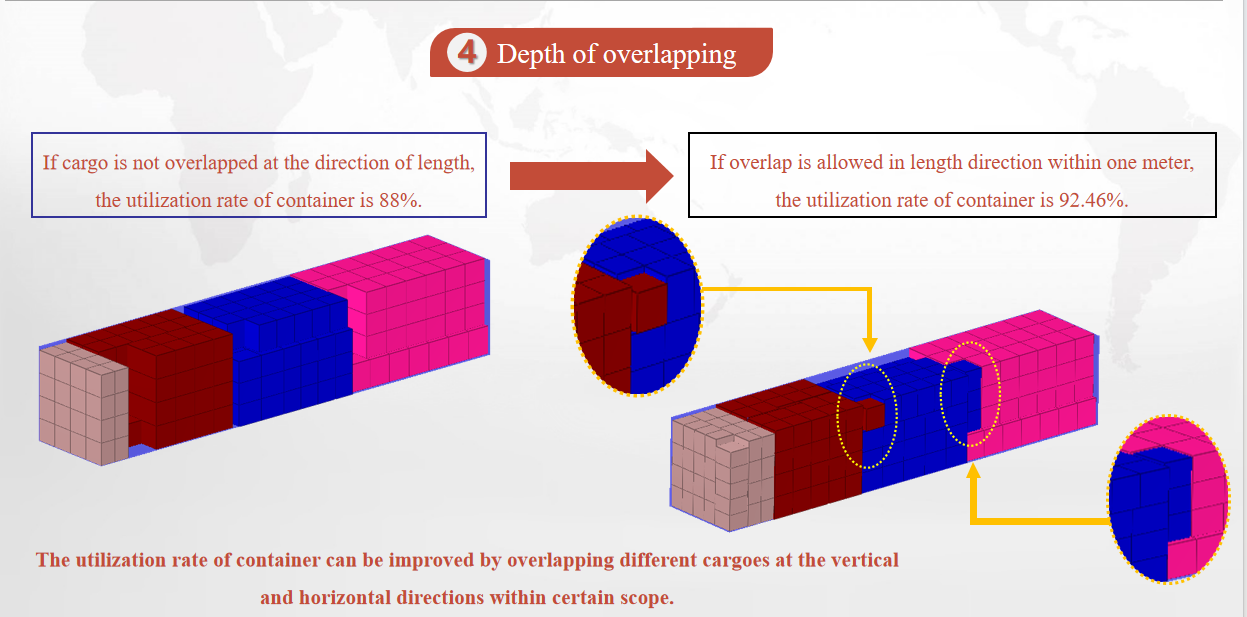

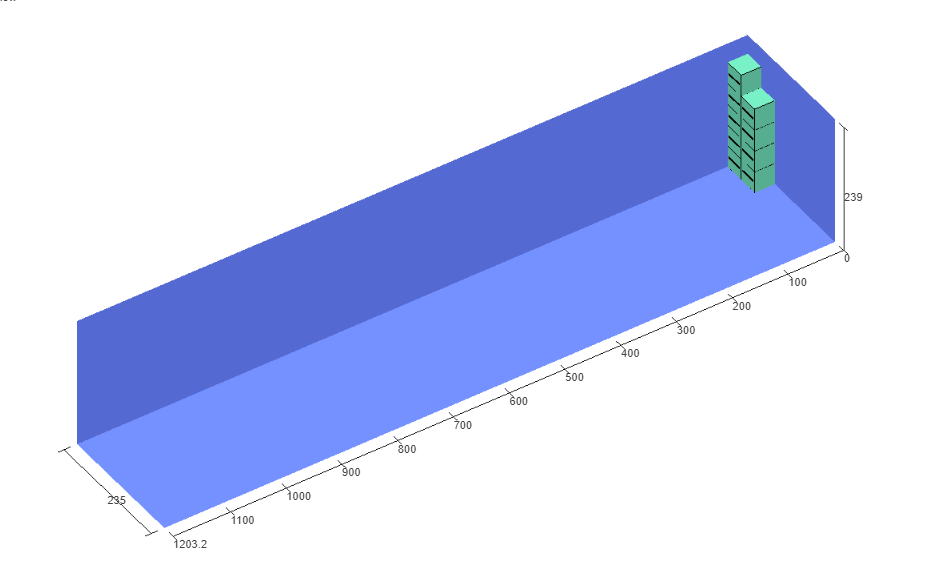

Cross depth refers to the maximum crossing range of cargoes at adjacent layers in the direction of container length when stacking them in container loading. When the value of it is 0, the cargoes of different kinds will not cross each other in the length direction when stacking. In actual operation, allowing a moderate range of cross can improve the loading efficiency, without increasing the complexity of loading, as shown below:

Let’s use an example to explain how cross depth can help optimize load planning in logistics. The cargo data and container loading requirements are as follows.

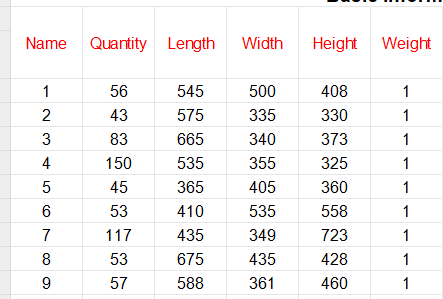

Cargo data:

Cargo loading requirements:

1.To load these pieces of cargo into 40GP.

2.When stacking, the same kind of cargo should try to be placed together instead of being mixed with others.

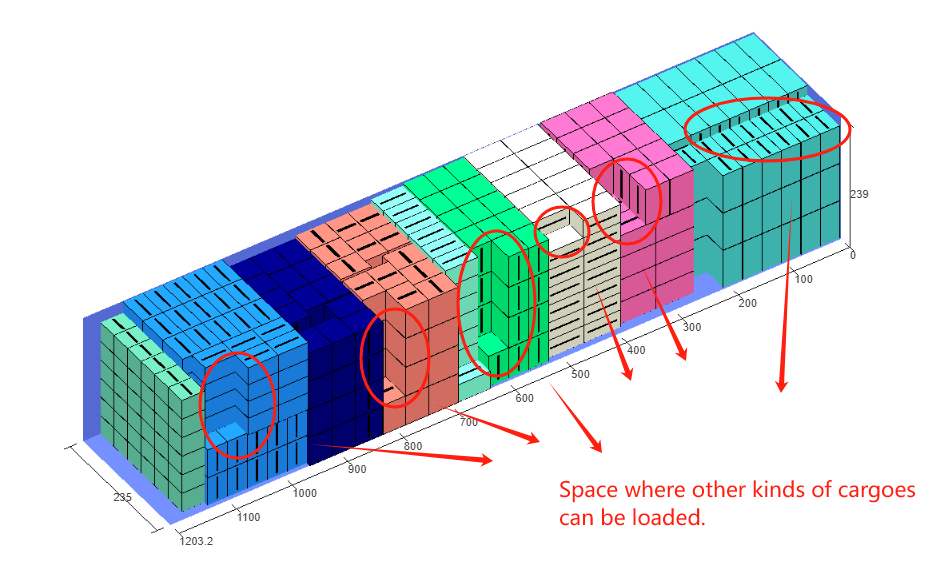

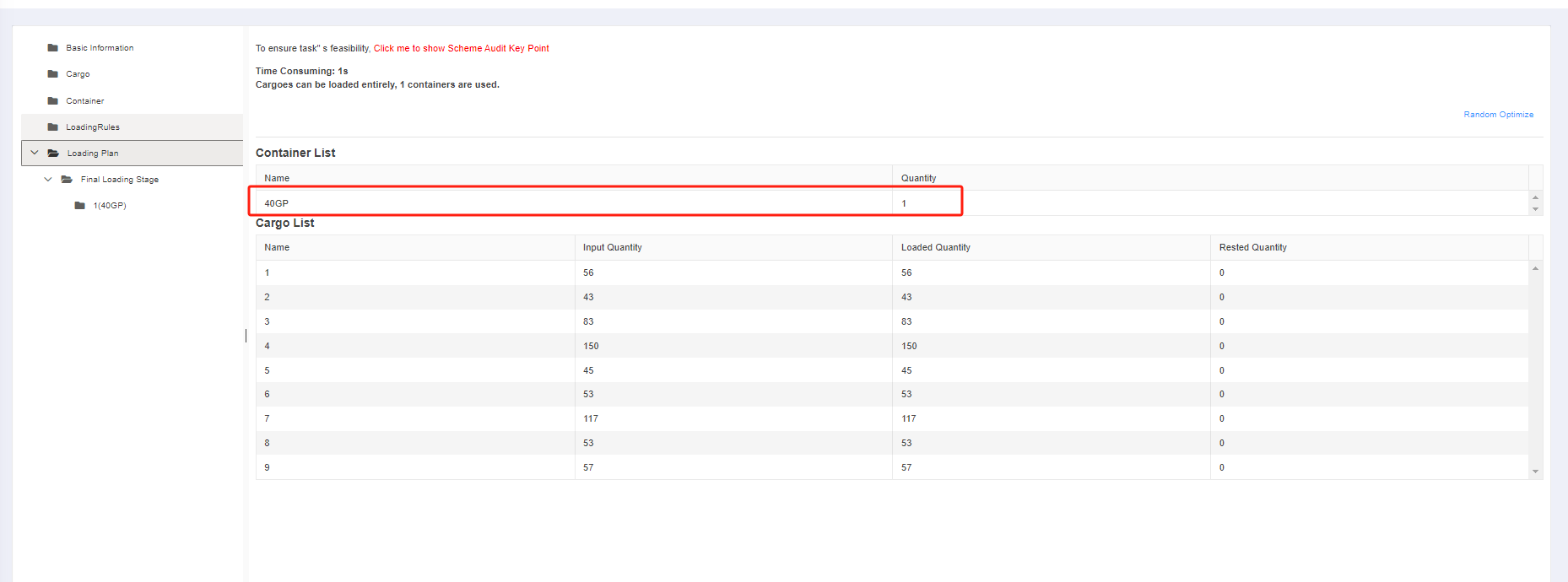

After uploading the cargo data into LoadMaster, adding the container, and checking the rule “Place the same cargoes next to each other” we can get the 3D container loading diagram within seconds. Then we can see that two 40GP are used and the same kind of cargoes are placed together, but in the second one, there are only 9 pieces of cargo loaded, such a waste of container space!

How to fix that? Here comes cross depth.

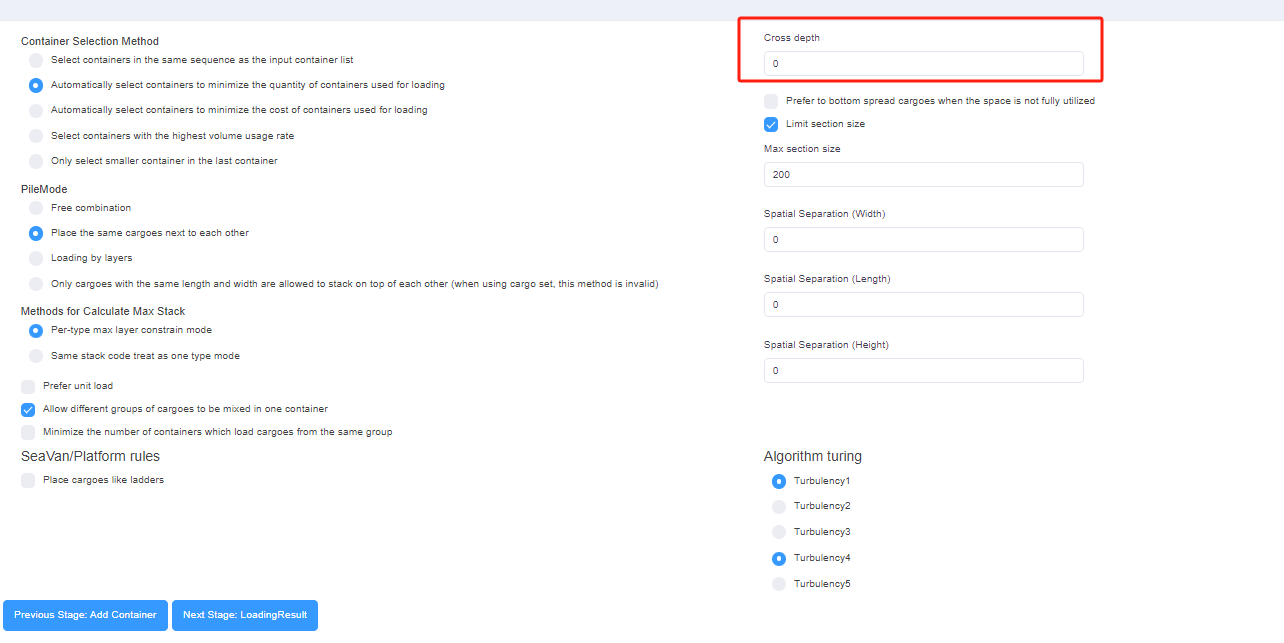

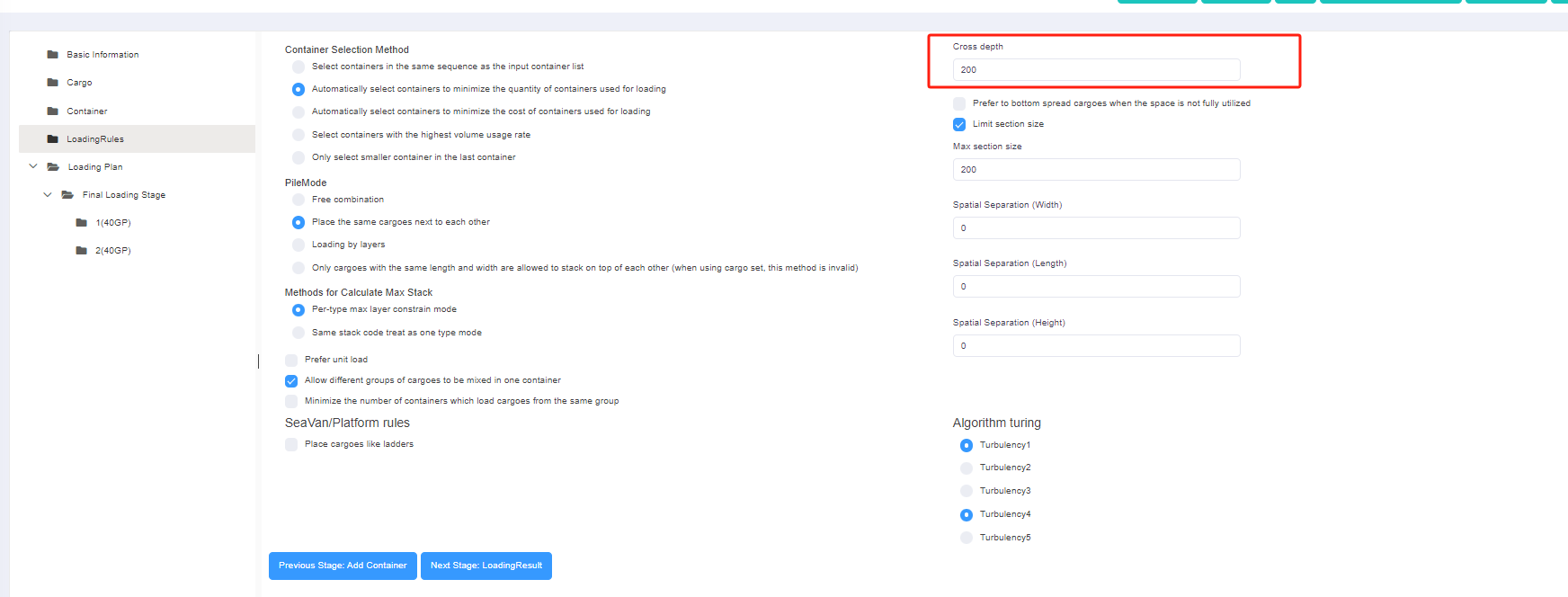

Enter the Loading Rules interface, locate the cross depth. We can see at the first beginning, the value of cross depth is 0cm, which means even if there is still space on the top layer of one kind of cargo, other kinds of cargoes won’t be mixed together.

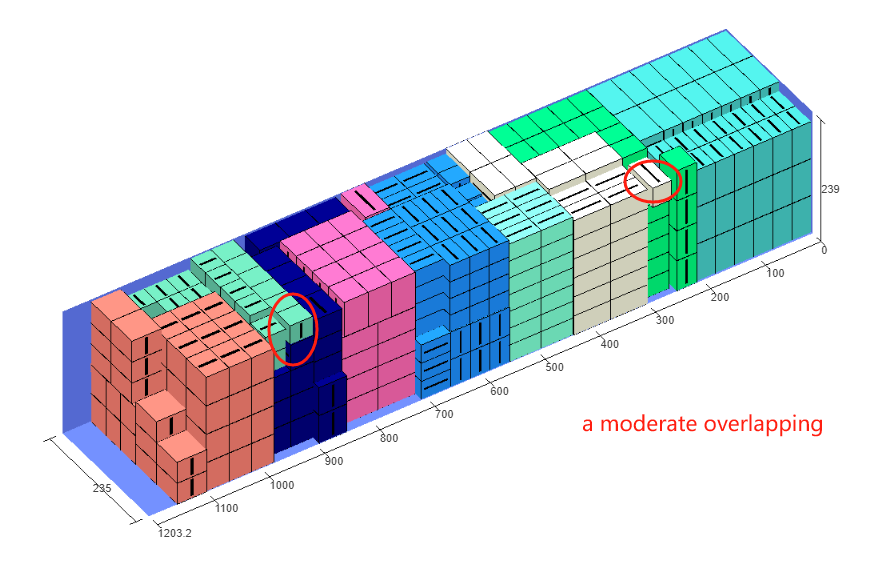

But if we allow a moderate range of overlapping, these pieces of cargo can be filled in the remaining space without increasing the complexity of on-site loading but can indeed save one container.

Let’s try it!

Change the value of cross depth from 0 to 200cm, and then click “Loading Result”. Wow! Only one 40GP is used! One 40GP is saved, which means one container’s costs and may result in more profits!

Through the comparison of the above two container loading solutions, it is evident that cross depth, while meeting the packing requirement of “placing the same kind of items adjacent to each other,” holds practical significance in improving the container loading rate.