There is a common container loading requirement in home appliance industry while shipping goods. When loading the container on site, sometimes the products for example refrigerators are required to be placed with the height vertical to the ground as much as possible. If there is remaining space on top of these cargoes on the first layers and also cargoes left, then they can also be placed with the width vertical to the ground for another one or two layers. How to realize this in LoadMaster 3D cargo loading software?

Let’s check it out with an example.

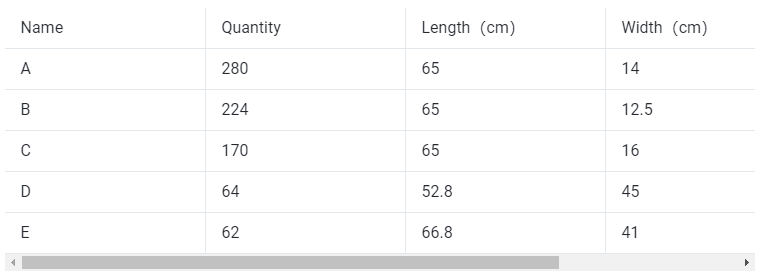

Cargo data:

Container loading requirements:

1.Cargo A B C had better to be placed with the height vertical to the ground as much as possible. If there is remaining space after vertical loading, they can be placed with the width vertical to the ground for another one or two layers.

2.Calculate how many 40HC are used to load all these cargoes.

According to the container loading requirements, the task type [Loading Container/Multiple Cargoes] should be selected.

Enter the [Basic Information] interface. Users can fill in the “Name” with the PO number, order number or destination information. Next, start to design the plan:

Step 1: Click [Cargo] on the left to enter the cargo interface. For there are lots of cargo types, it’s better to add them in batches through a container loading excel template. Firstly, click [Add Cargo>Get Excel Template] to download the container loading Excel template and save it to a certain location in your computer.

Secondly, fill in the template with the cargo information.

①Copy the name, quantity, length, width, height, and weight (gross weight of a single carton) of the goods into the template, which are required items. Pay attention to the matching of the units. “Weight”refers to the gross weight of a single carton or box of goods. If the cargo is too light, the “Weight”can be ignored and not filled in, and the system will default it as “1”.

②In this example, cargo A, B, C had better to be placed with the height vertical to the ground as much as possible. If there is space on the top of the vertically loaded cargoes, then cargoes can be placed with the width vertical to the ground for another one or two layers. That is, the goods cannot be placed with the length is vertical to the ground. Fill in the “Allow” column under “lay” and “lay & rotate” with “0”, “0” means not allowed, “1” or leaving it blank means allowed.

Fill in the “Max stack” column under A, B, C’s “Side” and “Side & rotate” with a smaller number “2”. But the number of this value is not fixed, you can adjust it based on the 3D load planning result.

Fill in the “Support others” column under ABC’s “Side” and “Side & rotate” with “0”, “0” means not allowed, “1” or blank means allowed.

For there are no other cargo loading requirements, leave other parameters as default. Save and close the template when finishing it.

Step 2: Click [Container] on the left to enter the [Container] interface. For the user does not know the type and quantity of the container that should be used, it is necessary to add all the frequently used container types to the 3D container loading calculator so that the system can automatically select the most appropriate container type.

For the frequently used container information is already maintained in the container database, click [Import from Database], check the 20GP, 40GP and 40HC in the pop-up box, and then click [Add]. Edit the corner castings size and reserved size of the container, the size of the corner castings is 10×10×10cm.

Step 3: Click [Loading Rules] on the left to enter the [Loading Rules] page. For there are no special container loading rules, leave them as default.

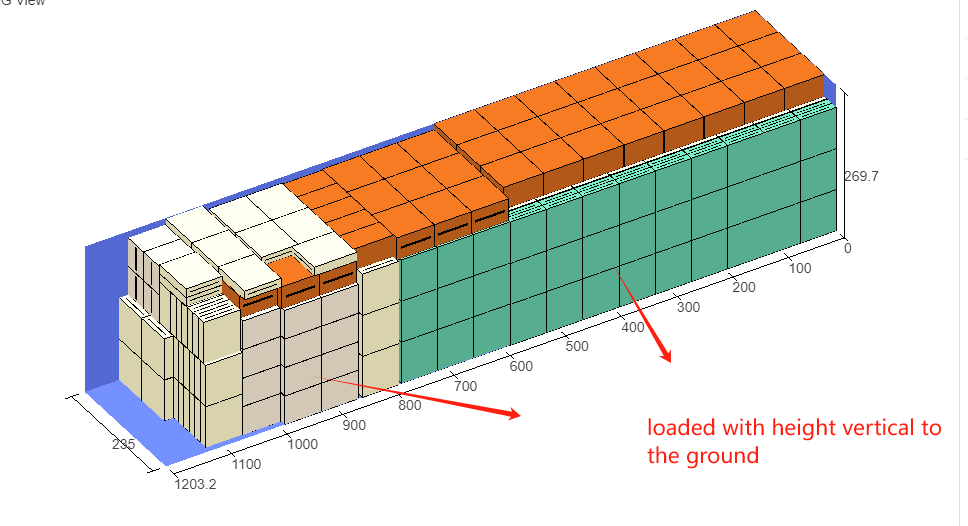

Click [Loading Result] above to get the 3D container loading plan. In the list on the left, you can see that this batch of products has been loaded in one 40HC. In the middle is the 3D overview of the cargo loading effect. It can be seen from the 3D diagram that most of A, B, C are vertically loaded. Since there is still remaining space on top of these cargoes, so two layers of cargoes are loaded with the width vertical to the ground, which fully meets the loading requirement.