When the software is calculating how to arrange different kinds of cargo on pallets, it loads cargo on the pallets layer by layer, which means the second layer of cargo can only be generated after the first layer is finished loading on pallets. But since different kinds of cargo have different sizes and quantity, so when arranging their stacking, it is unavoidable that there will be a difference in height between different kinds of cargo and other possibilities that would affect the mixing of cargo on pallets. Therefore, LoadMaster load planning software has made some loading rules with regard to the mixing of cargo on pallets. Let’s have a look!

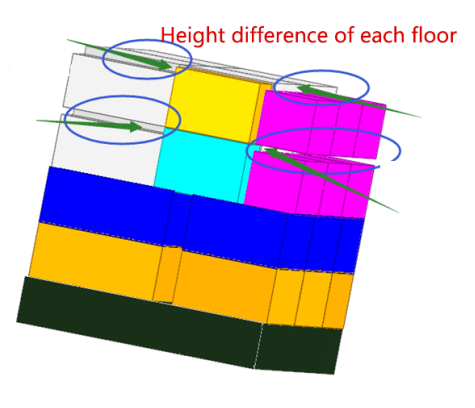

1.Maximum negligible height difference

When stacking cargo of different kinds on a pallet layer by layer, the layer may be not flat due to different cargo sizes and quantity. Therefore, users need to define the acceptable maximum height difference of each layer of cargoes in advance, which is the [Maximum negligible height difference] so that within the range of this difference, the height difference will be regarded as negligible and this layer can be regarded as flat. The next layer can be generated.

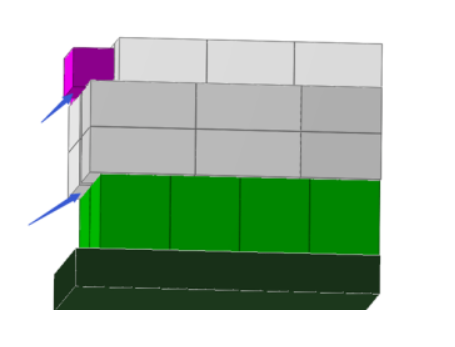

2.Minimum floor area coverage(%)

The minimum floor area coverage refers to the user’s minimum acceptable ratio between the bottom area of a layer of cargoes and the bottom area of the pallet.

When the coverage of a layer of cargoes reaches the minimum floor area coverage, the current layer is regarded as a fully covered layer.

In the following example, the minimum floor area coverage set by the user is 82%.

(1)The bottom green cargoes has reached the requirement of 82% floor area coverage, so they are placed as a layer.

(2)The gray cargoes in the middle has also reached the requirement of 82%, so they are placed as a layer.

(3)However, when the floor area coverage ratio of the upper layer (middle gray cargo layer) is bigger than the coverage rate of the lower layer (green cargo layer), the phenomenon of overhang will appear.

(5)Although there are vacancies and dangling in the side and corner, in actual operation such situations can be prevented by dispersing and adding buffers.

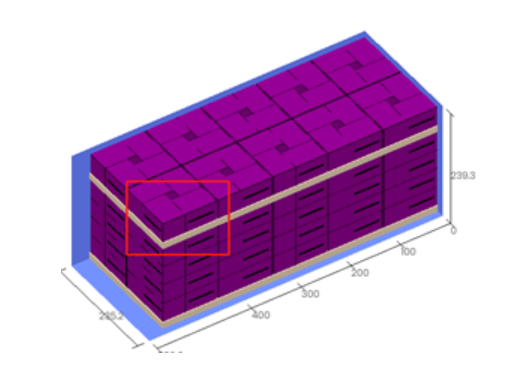

3.Acceptable minimum height of pallet

Minimum acceptable height of pallet refers to the minimum height of the filled pallet on the top when the pallet is dynamically generated according to the height of the container.

(1)If the [Minimum acceptable height of pallet] is set too small, sometimes only one layer of cargoes will be loaded on one pallet.

(2) If the [Minimum acceptable height of pallet] is set too large, some cargoes will be directly loaded into the container without being loaded onto pallets.

Therefore, it is recommended to calculate the results based on the default value first. And adjust the value according to the final 3d load plan.

4.Pallet Bearing Capacity Calculate

The default stacking orders of mixed pallets is used to define the stacking orders of the pallet and the directly loaded cargoes.

(1)Mixed pallets refer to pallets calculated by the system.

(2)The default stacking orders of the pallet is 254(the maximum value), which means that the pallet has the strongest loading capacity.

(3) When the loading capacity of pallet is poorer than some other cargoes (such as iron boxes and wooden boxes), please modify this parameter to ensure that the stacking orders of this pallet is less than that of other cargoes.