𝗖𝗼𝗺𝗽𝗮𝗻𝘆 𝗕𝗮𝗰𝗸𝗴𝗿𝗼𝘂𝗻𝗱

LiuGong Machinery Corp., Ltd. is a leading Chinese construction machinery manufacturer with a global presence covering Asia, Europe, America, Africa and so on. As the first listed company in the engineering machinery industry in China and Guangxi, Liugong is hailed as “the vanguard of China’s engineering machinery industry”. Established in 1958, LiuGong has grown into one of the world’s largest manufacturers of wheel loaders. LiuGong’s product lineup covers a comprehensive range of construction machinery, including excavators, bulldozers, motor graders, compactors, skid steer loaders, forklifts, and more. These machines are known for their reliability, durability, and high performance, making them popular choices for construction projects worldwide.

𝗕𝗲𝗳𝗼𝗿𝗲 𝘂𝘀𝗶𝗻𝗴 𝗟𝗼𝗮𝗱𝗠𝗮𝘀𝘁𝗲𝗿:

According to their business director, “since 2021, their export volume of equipment parts has been steadily increasing. More and more wooden crates/pallets carrying engineering machinery parts need to be shipped out. However at that time, our company encountered the following difficulties which blocked our improvement.

1.The loading rate of containers was relatively low, with a 40-foot HC container basically only accommodating around 40m3 of parts, resulting in significant waste of remaining space.

2.Prior to shipping, we solely relied on manual calculations for container loading plans. Due to the numerous types and sizes of wooden crates/pallets, the calculation process was not only time-consuming but also unable to meet specific loading requirements or provide direct guidance to the onsite loading staff.

Therefore, in a scenario where neither business demands nor existing conditions were being met, we hoped to automate calculations through intelligent load planning software, visually displaying loading diagrams to facilitate smooth business operations.”

Last year, through online searches and other companies’ recommendations, they selected several software companies as options. After trial and comparison, they told us that they found that LoadMaster was the most suitable for our company’s business needs.

𝗛𝗼𝘄 𝗟𝗼𝗮𝗱𝗠𝗮𝘀𝘁𝗲𝗿 𝗰𝗮𝗻 𝗺𝗲𝗲𝘁 𝘁𝗵𝗲𝗶𝗿 𝗻𝗲𝗲𝗱𝘀:

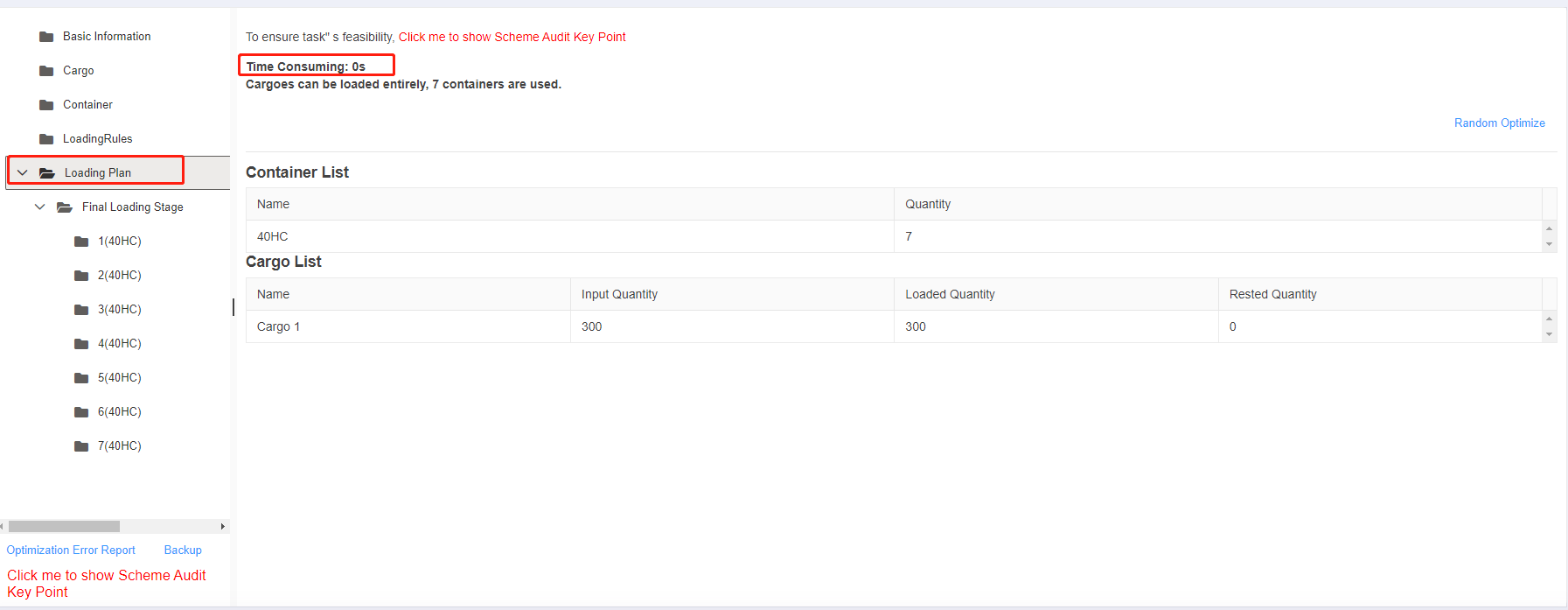

1.Firstly, LoadMaster can calculate how to palletize and how to containerize. Regarding container loading, importing templates is convenient, allowing selection of corresponding settings based on loading requirements.

2.Results are typically available within 1-2 minutes, eliminating long waits, and with six algorithmic combinations, offering multiple loading solutions.

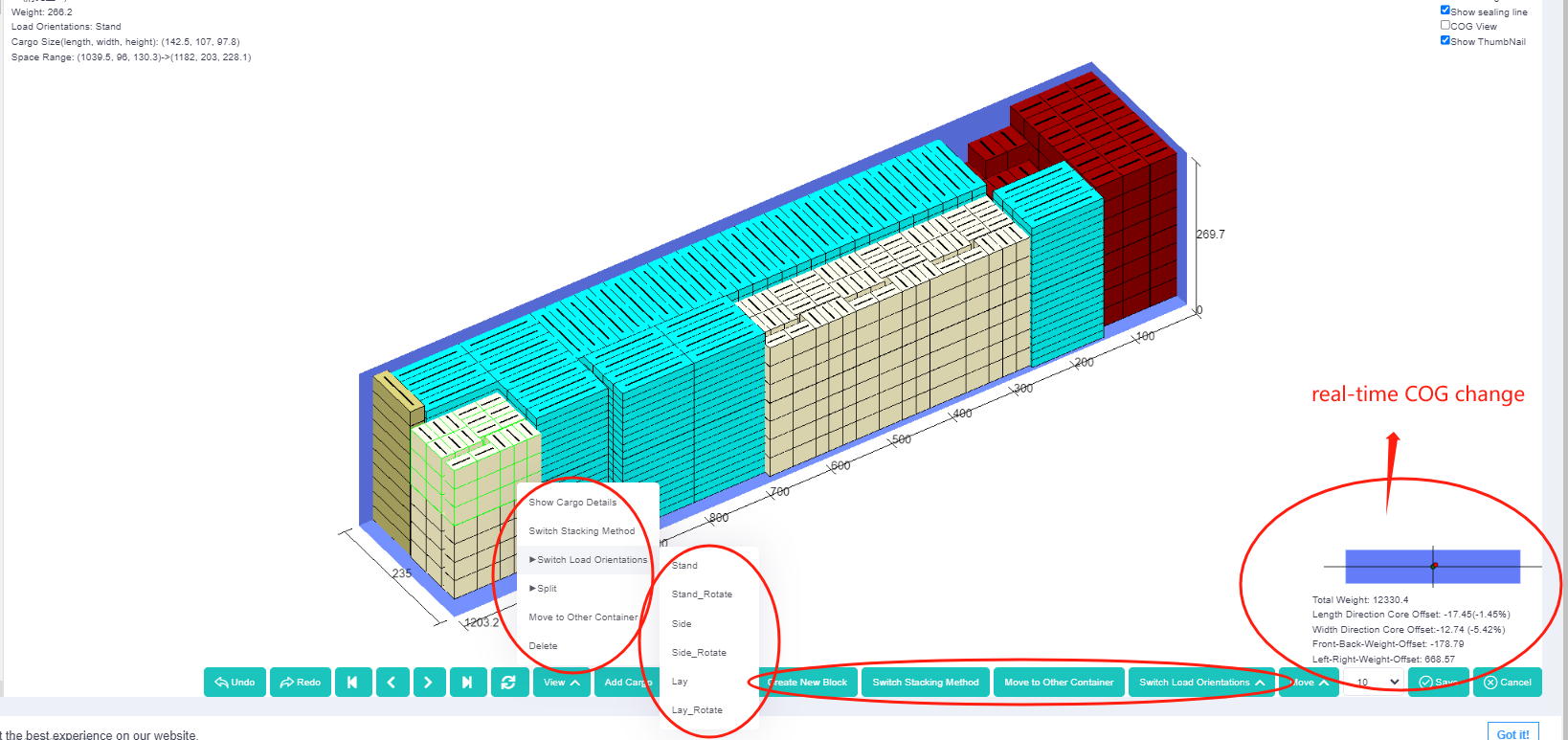

3.Furthermore, the manual edit of LoadMaster is particularly useful. Their cargo dimensions are complex, and relying solely on software-generated solutions isn’t sufficient, necessitating adjustments through manual edit to align with actual loading operations.

“In terms of service, customer service representatives always respond promptly and accommodate our requests, which we greatly appreciate.”

𝗤𝘂𝗮𝗻𝘁𝗶𝘁𝗮𝘁𝗶𝘃𝗲 𝗕𝗲𝗻𝗲𝗳𝗶𝘁𝘀:

Following the adoption of this software, over the past year, Liugong’s container utilization rate has significantly increased. A 40-foot high cube container, which previously accommodated only 40+ cubic meters, now holds up to 55 cubic meters, a more than 20% increase in loading capacity.

Container loading time has been reduced from 1-2 days to less than an hour. The 3D view of the loading scheme is intuitive, directly informing customers about available remaining space, convenient for the communication on adjusting cargo quantity, resulting in satisfactory feedback. LoadMaster load planning software has expedited the warehouse prestocking and significantly promoting their business development.

You can know how LoadMaster has helped 𝗮𝘃𝗼𝗶𝗱 𝗰𝗮𝗿𝗴𝗼 𝗹𝗲𝗳𝘁 𝗮𝗻𝗱 𝘂𝗻𝗹𝗼𝗮𝗱𝗲𝗱 for Shatian Hanjun Metal Products Factory at https://blog.loadmaster.biz/2023/07/25/14/ .