For any enterprise, different stages of development come with varying methods and channels for cost reduction and efficiency improvement.

In the 𝗦𝘁𝗮𝗿𝘁𝘂𝗽 phase, when the company’s scale has not yet formed, the primary goal is to establish market demand for products or services and brand awareness. Therefore, the focus is on controlling expenses, reducing initial investments, and operating costs. Cost reduction can be achieved by in-house production, seeking affordable suppliers, and employing basic marketing strategies.

As the company progresses to the 𝗚𝗿𝗼𝘄𝘁𝗵 stage, it begins to scale up, increase market share, and expand its customer base. The objective shifts to accelerating growth, increasing sales revenue and profits, and establishing a competitive advantage in the industry. At this stage, as the company expands, more funding is needed to support growth. The emphasis is on improving production and operational efficiency to lower unit costs. Cost reduction can be achieved through automating production processes, optimizing the supply chain, and negotiating more favorable procurement prices.

For 𝗠𝗮𝘁𝘂𝗿𝗲-stage enterprises that have established a certain brand and customer base in the market, cost reduction can be achieved through scaled production and refined management.

Therefore as a company continues to grow and its business becomes more mature, achieving cost reduction and efficiency improvement increasingly requires attention to “detail”. Cargo loading software assists in achieving these benefits by helping you optimize and maximize container loading efficiency. Let’s take a closer look at how a qualified software can help you gain benefits from details!

𝗧𝗵𝗲 𝗯𝗲𝘀𝘁 𝘄𝗮𝘆 𝘁𝗼 𝗹𝗼𝗮𝗱 𝗮 𝘀𝗵𝗶𝗽𝗽𝗶𝗻𝗴 𝗰𝗼𝗻𝘁𝗮𝗶𝗻𝗲𝗿? 𝗟𝗼𝗮𝗱 𝗽𝗹𝗮𝗻𝗻𝗶𝗻𝗴 𝘀𝗼𝗳𝘁𝘄𝗮𝗿𝗲!

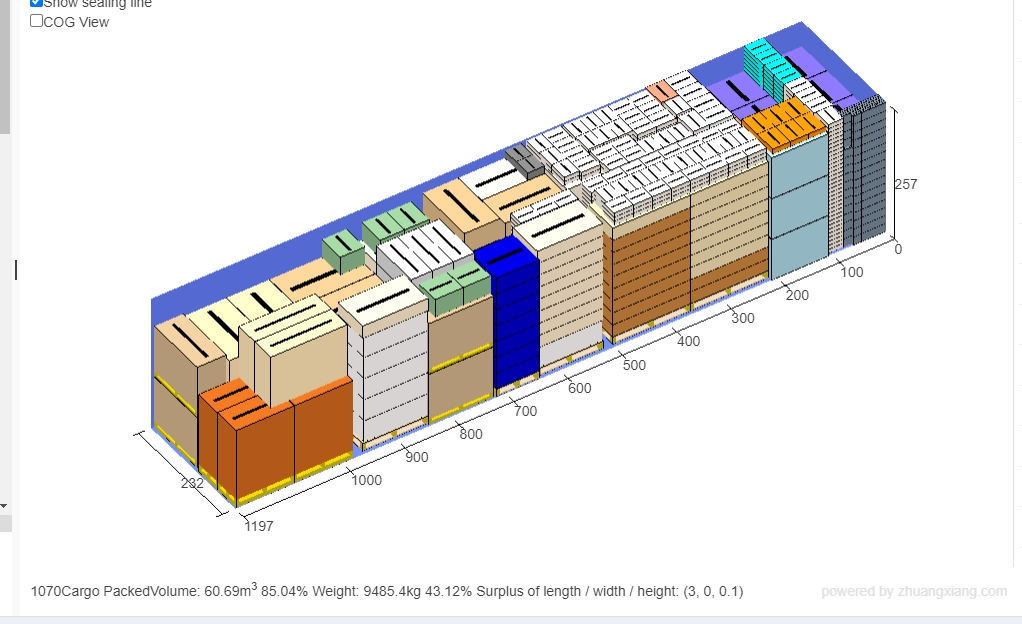

Cargo packing software optimizes the calculation of loading in containers, trucks, trailers, and pallets, maximizing the use of space within the containers to increase loading rates and reduce the unit transportation cost of goods, thereby reducing freight costs and minimizing cargo damage.

For 𝘀𝗵𝗶𝗽𝗽𝗲𝗿𝘀 (often manufacturing companies in various industries such as automotive parts, household appliances, furniture, and mechanical equipment), optimization through software often leads to higher loading rates compared to previous loading levels. Higher loading rates may imply 𝗶𝗻𝗰𝗿𝗲𝗮𝘀𝗲𝗱 𝘀𝗵𝗶𝗽𝗺𝗲𝗻𝘁 𝘃𝗼𝗹𝘂𝗺𝗲𝘀, resulting in higher profits. For cargo 𝗿𝗲𝗰𝗲𝗶𝘃𝗲𝗿𝘀, the same container/truck with the same space can accommodate more goods, 𝗿𝗲𝗱𝘂𝗰𝗶𝗻𝗴 𝘁𝗵𝗲 𝘂𝗻𝗶𝘁 𝘁𝗿𝗮𝗻𝘀𝗽𝗼𝗿𝘁𝗮𝘁𝗶𝗼𝗻 𝗰𝗼𝘀𝘁 𝗼𝗳 𝗴𝗼𝗼𝗱𝘀. Thus, higher profits are achievable if the goods are sold at the original price. Even if the goods are sold at a slightly reduced price, the market competitiveness of the goods will be higher. Therefore no matter it is maintaining the original price or cutting down a bit, increased benefits for the receiving party can be guaranteed, leading to significantly higher satisfaction of them.

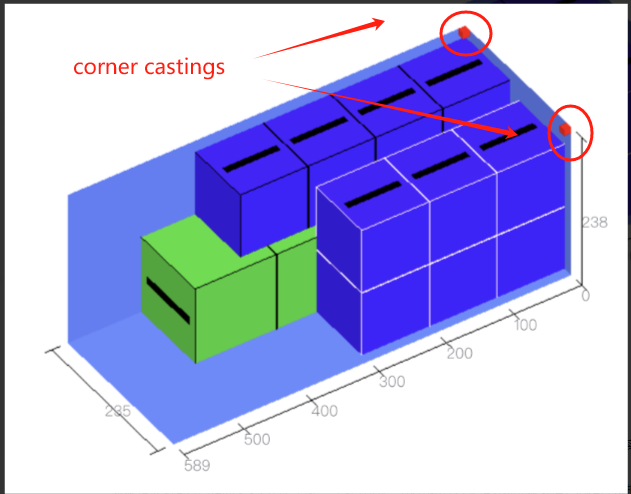

Compared to manually calculated loading solutions, load plans backed up by container loading optimization algorithm is more 𝘀𝗰𝗶𝗲𝗻𝘁𝗶𝗳𝗶𝗰. After fully simulating scenarios such as the 𝗰𝗼𝗿𝗻𝗲𝗿 𝗰𝗮𝘀𝘁𝗶𝗻𝗴𝘀 inside the container (which occupy a certain space and must be considered in the calculation scheme, otherwise there may be a result where the software fits but the actual loading does not fit), 𝗰𝗮𝗿𝘁𝗼𝗻 𝗲𝘅𝗽𝗮𝗻𝘀𝗶𝗼𝗻, and 𝗺𝗮𝗻𝘂𝗮𝗹 𝗴𝗮𝗽 𝗽𝗹𝗮𝗰𝗲𝗺𝗲𝗻𝘁, the software designs a 3D loading plan with a higher loading rate, while minimizing cargo damage and container overload. With accurate 3d load plans, accurate customs declaration, and fast customs clearance can also be achieved.

𝗜𝗻 𝘁𝗵𝗶𝘀 𝘄𝗮𝘆, 𝗻𝗼𝘁 𝗼𝗻𝗹𝘆 𝗶𝘀 𝘁𝗵𝗲 𝗹𝗼𝗮𝗱𝗶𝗻𝗴 𝗿𝗮𝘁𝗲 𝗶𝗻𝗰𝗿𝗲𝗮𝘀𝗲𝗱 𝗮𝗻𝗱 𝗰𝗮𝗿𝗴𝗼 𝗱𝗮𝗺𝗮𝗴𝗲 𝗿𝗲𝗱𝘂𝗰𝗲𝗱, 𝗯𝘂𝘁 𝘁𝗵𝗲 𝗲𝗻𝘁𝗶𝗿𝗲 𝗽𝗿𝗼𝗰𝗲𝘀𝘀 𝗯𝗲𝗰𝗼𝗺𝗲𝘀 𝗽𝗿𝗲𝗱𝗶𝗰𝘁𝗮𝗯𝗹𝗲, 𝗺𝗮𝗻𝗮𝗴𝗲𝗮𝗯𝗹𝗲, 𝗮𝗻𝗱 𝘁𝗿𝗮𝗰𝗲𝗮𝗯𝗹𝗲, 𝗵𝗲𝗹𝗽𝗶𝗻𝗴 𝗰𝗼𝗺𝗽𝗮𝗻𝗶𝗲𝘀 𝗮𝗰𝗵𝗶𝗲𝘃𝗲 𝘀𝘁𝗮𝗻𝗱𝗮𝗿𝗱𝗶𝘇𝗲𝗱 𝗮𝗻𝗱 𝘁𝗿𝗮𝗻𝘀𝗽𝗮𝗿𝗲𝗻𝘁 𝗺𝗮𝗻𝗮𝗴𝗲𝗺𝗲𝗻𝘁 𝗼𝗳 𝘁𝗵𝗲 𝗲𝗻𝘁𝗶𝗿𝗲 𝗼𝗿𝗱𝗲𝗿 𝘀𝗵𝗶𝗽𝗽𝗶𝗻𝗴 𝗽𝗿𝗼𝗰𝗲𝘀𝘀, 𝘁𝗵𝗲𝗿𝗲𝗯𝘆 𝗲𝗻𝗮𝗯𝗹𝗶𝗻𝗴 𝘁𝗵𝗲𝗺 𝘁𝗼 𝗰𝗿𝗲𝗮𝘁𝗲 𝘃𝗮𝗹𝘂𝗲 𝗮𝗻𝗱 𝗴𝗮𝗶𝗻 𝗯𝗲𝗻𝗲𝗳𝗶𝘁𝘀 𝗳𝗿𝗼𝗺 𝗱𝗲𝘁𝗮𝗶𝗹𝘀!

If you haven’t tried online cargo loading software yet, why not give it a try yourself?