In railway and maritime transportation, in addition to maximizing container (such as containers, trailers, and trucks) load rates to reduce the unit transportation cost of goods, it is also important to minimize cargo damage and reduce unnecessary cost expenditures. This places demands on the safe loading and transportation of goods.

According to feedback from clients of LoadMaster container loading software, railway bureaus, customs, and some international shipping organizations have strict rules for cargo center of gravity offsets to ensure the safe transportation of goods. Failure to comply with these rules may result in fines and requirements for reloading, leading to unnecessary expenses such as reloading fees, unloading fees, and may also affect the timely delivery of goods, thereby impacting customer satisfaction and hindering the long-term development of enterprises.

In general, when loading cargo, the center of gravity of the cargo can be kept basically consistent with the center of the container. Therefore, during transportation, the container will not be unbalanced.

However, when heavy and light cargoes are mixed to load in a container, it is essential to adjust the layout and maintain balance. This situation often occurs during consolidation shipments, and sometimes freight forwarders profit from adjusting the center of gravity.

To address this issue, it is only possible to adjust the distribution of weight through reasonable allocation of heavy and light cargo. It is necessary to know the positions of the container center and the cargo center of gravity before adjusting. However, the time and labor costs of on-site adjustments are high.

Neglecting the balance of the container can lead to many safety hazards. Some countries’ shipping companies may impose fines on the export party of unbalanced containers, known as container imbalance additional fees (EBS, CIC). So, how to achieve balance of the container?

Previously, the balance of the container could be achieved by relying entirely on the experience of the container loading master. Experienced loaders could evenly distribute cargo of different weights in the container based on intuition. However, new-hand loaders often find it difficult. Nowadays, finding an experienced container loader is not only difficult but also requires paying 2-3 times the salary of a new-hand loader. And it’s not manageable or scientific to totally rely on the guidance of these experienced loaders. What if one day they are unavailable due to illness or other reasons? Then it can cause significant trouble to the entire operation.

Nowadays, with the help of scientific algorithms in container loading optimization software, achieving balance of the container is possible. Specific requirements for different transportation institutions may vary:

According to experiments conducted by Japanese experts, when the container loading weight approaches the max, it is necessary to ensure that the center of gravity offset is within 10% of the center of container. This prevents cargo damage during crane lifting at the terminal. If the container loading weight is less than the limit, the center of gravity offset can slightly exceed 10%.

As for railway transportation, the Zhengzhou Railway Bureau has relatively strict rules. For general cargo, the weight difference between the front and rear cargo should not exceed 2 tons, and the weight difference between the left and right cargo should not exceed 500kg, with the longitudinal centerline as the boundary.

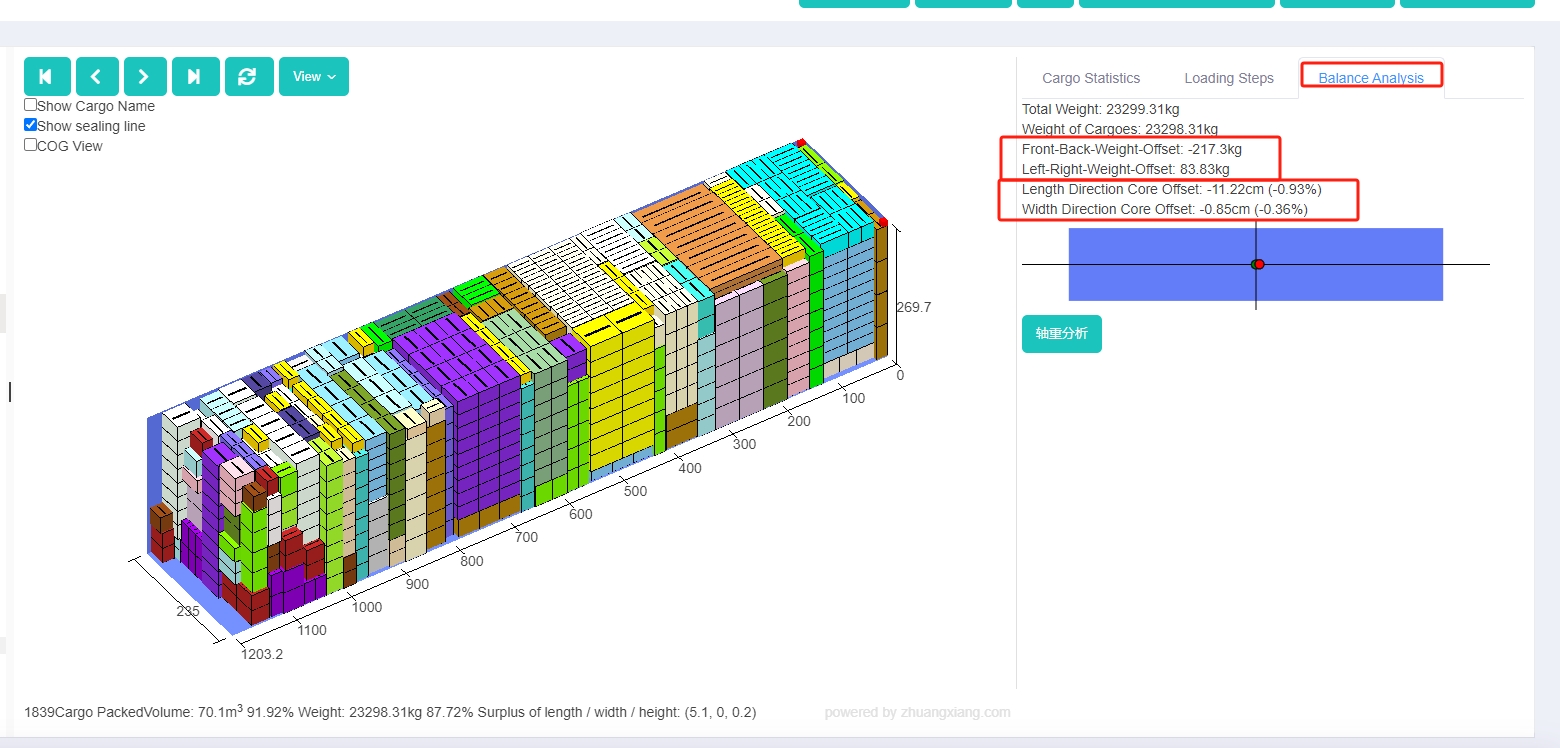

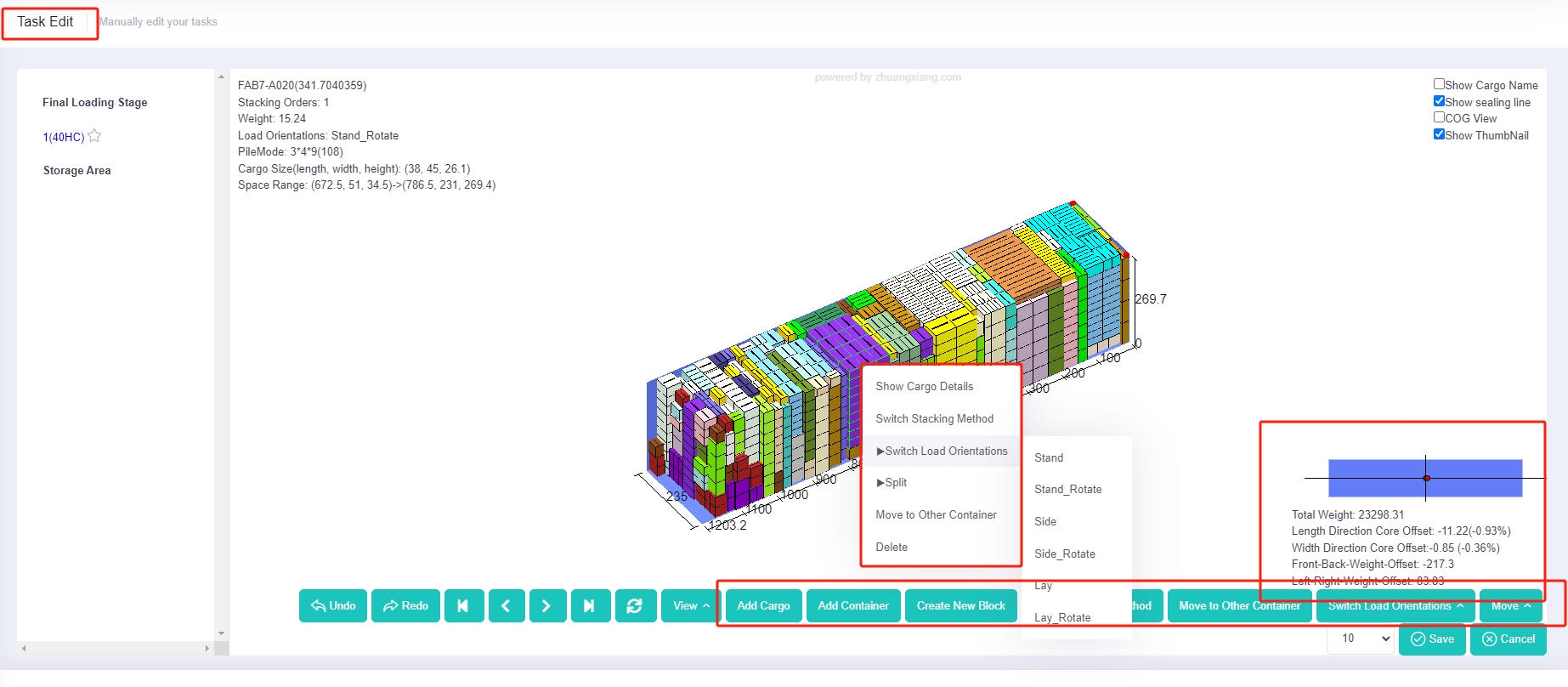

With the balance analysis function in container loading software, it is possible to determine the distribution of cargo center of gravity and whether it falls within the required range. If there is an offset, manual editing functions can be used for adjustments.

(

( (

(