In modern logistics and transportation, containers play a crucial role. The stability and safety of containers often rely on one of their components: corner fittings/castings. This article delves into the definition and function of container corner fittings/castings, the importance of reserving space for corner fittings/castings while using container loading optimization software, and provides a case study to illustrate the reasons. Let’s see!

- What are container corner fittings/castings?

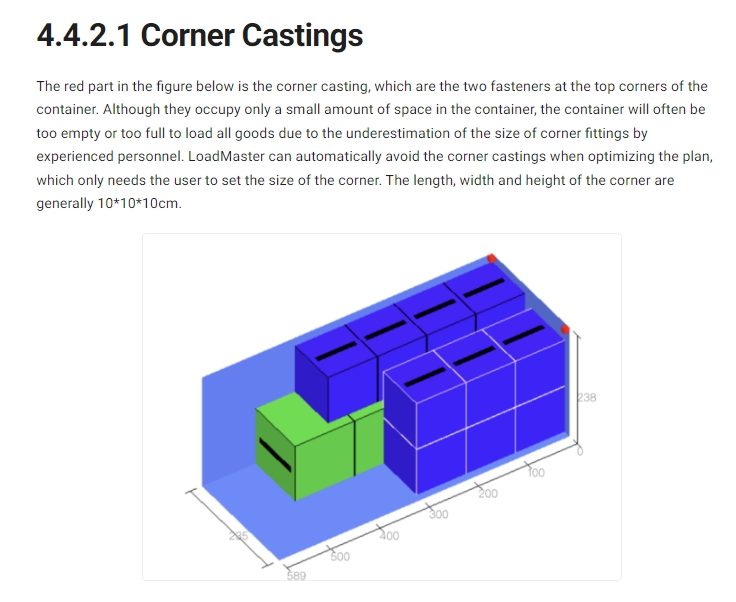

Simply put, container corner fittings/castings are components located at the internal top corners of shipping containers. Typically made of steel, and they are used to make the stacking of goods inside a 20GP/40GP/40HC more stable.

- What are the functions of corner fittings/castings?

Container corner fittings/castings serve multiple purposes:

- They offer stacking points, enabling containers to be safely stacked, thus saving space.

- Through connection and fixation, they ensure the safe transportation of goods inside the container.

The standard dimensions of a container corner fitting/casting are usually recognized as 10 cm × 10 cm × 10 cm. This standard size ensures compatibility with various types of containers and provides sufficient strength and stability.

- Why is it important to reserve space for corner fittings/castings when using container loading optimization software?

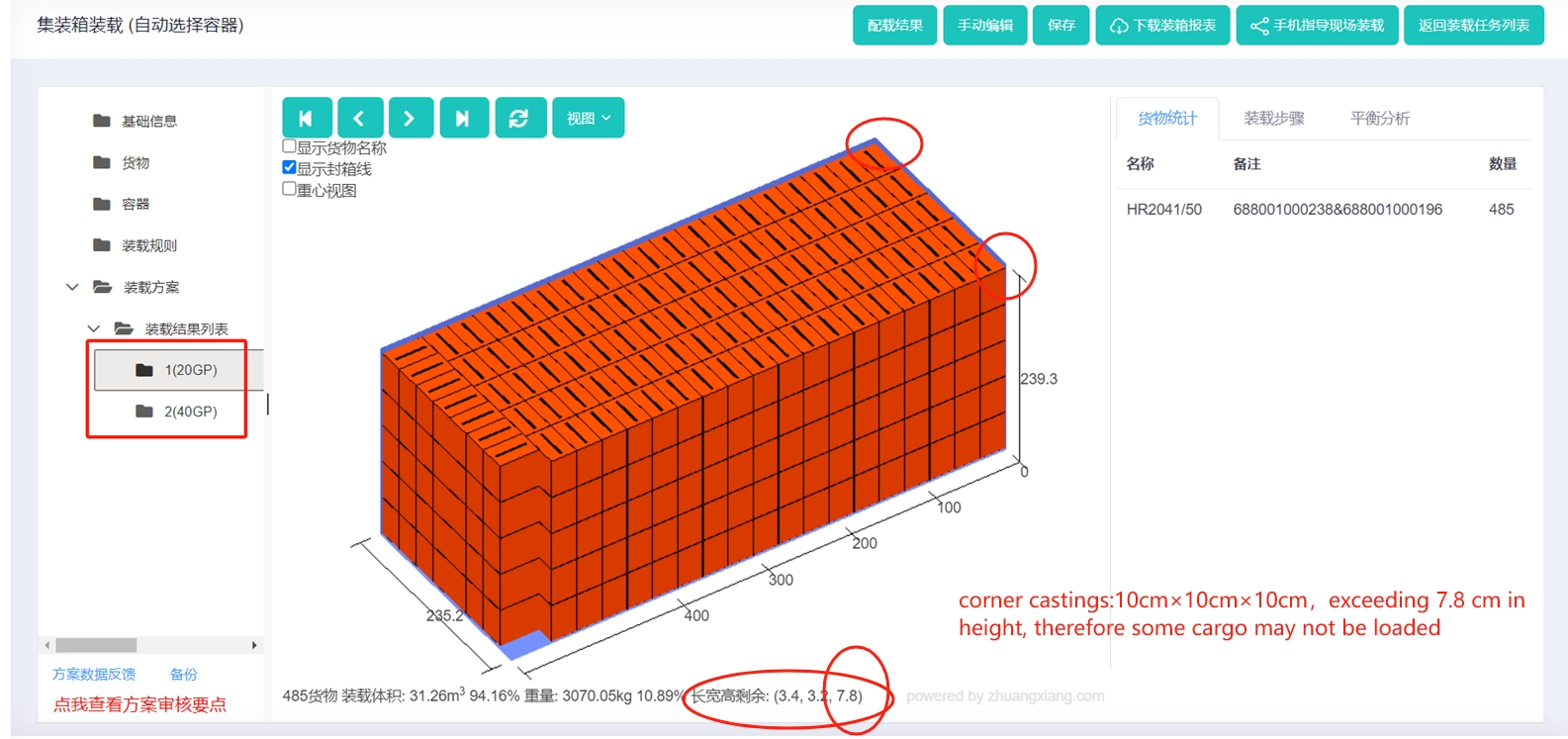

As for those where users can reserve space for corner castings like LoadMaster container loading software, after setting it, then the software would avoid corner castings when calculating the 3d load plan, meaning that the space taken up by corner castings would be deducted to simulate the on-site loading scenario to the largest extent.

- Case Study

LoadMaster once had a customer who did not set reserved corner fitting dimensions and failed to consider this when using the software. As a result, during actual loading, it was found that there was 7.8 centimeters of remaining vertical space in the container height direction, while the actual dimensions of the corner fittings were 10 cm × 10 cm × 10 cm, resulting in insufficient space to fit as much cargo as planned.

In conclusion, container corner fittings/castings are essential components for the safe transportation of goods. Reserving space for them while using container loading optimization software is crucial to ensuring safe and efficient cargo loading. Only then can the software simulate the actual loading scenario to the largest extent to maximize utilizing container space, thereby achieving safe and economically beneficial cargo transportation.