Mr. Wang from a logistics company had a requirement while using intelligent load planning software,”If we know the total weight of each pallet and the goods on it, as well as the maximum total weight of other pallets stacked on top of this pallet if more pallets are stacked on it, when planning, can the system calculate how many more pallets can be stacked on this pallet and which pallets to stack? Not only should it consider volume and height, but also ensure that the total weight of the pallets stacked above each pallet does not exceed the limit of its maximum loadable weight.”

After confirming with Mr. Wang, we learned that he wanted to address how to stack packed pallets of goods reasonably to avoid cargo damage and achieve safe loading. Mr. Wang’s idea was to arrange the stacking relationship between different SKUs based on the weight of them and the maximum weights they can bear.

How to solve this problem? Can the cargo loading software meet the requirements well? Don’t worry, let’s first know about cargo damage in transportation.

Cargo damage refers to the damage, loss, or destruction of goods that occur during transportation, storage, or handling. When goods are transported in containers, trucks, trailers, and other containers, the risk of cargo damage exists. For many enterprises, especially those involved in cargo transportation, achieving cost reduction and efficiency improvement at every stage of cargo transportation is becoming an increasingly important goal.

Excluding relatively uncontrollable probability events, such as collisions between transportation containers and other vehicles, facilities, obstacles, vibrations and displacements of goods caused by poor road conditions, adverse weather conditions, inadequate packaging leading to moisture, wear, scratches, or breakage of goods, and cargo damage caused by operational errors during loading and unloading, whether the stacking of goods is reasonable during loading and unloading is a relatively controllable factor with room for improvement.

Reasonably arranging the stacking of goods can minimize cargo damage, ensuring that goods are transported more securely. The palletizing software in this process helps enterprises achieve reasonable stacking and safe loading of goods, reduce the occurrence of cargo damage as much as possible, avoid unnecessary cost expenditures, and achieve cost reduction.

Whether it is the automotive parts industry with high product value, large weight, and volume, or industries such as medical, home appliances and electronics, furniture, and machinery equipment, there is a great demand for safe loading in the transportation of products. After all, there is no buyer who wants to receive damaged products, and no seller who wants to damage their image in the buyer’s mind.

How does today’s palletizing software solve this problem? Taking LoadMaster container loading software as an example, when stacking different goods in containers (such as standard containers, trucks, trailers, etc.), there are two common scenarios:

1.Only bulk cargo is loaded into the container, and the loading/bearing capacity of bulk cargo varies due to its own nature and packaging materials, so it needs to be reasonably stacked.

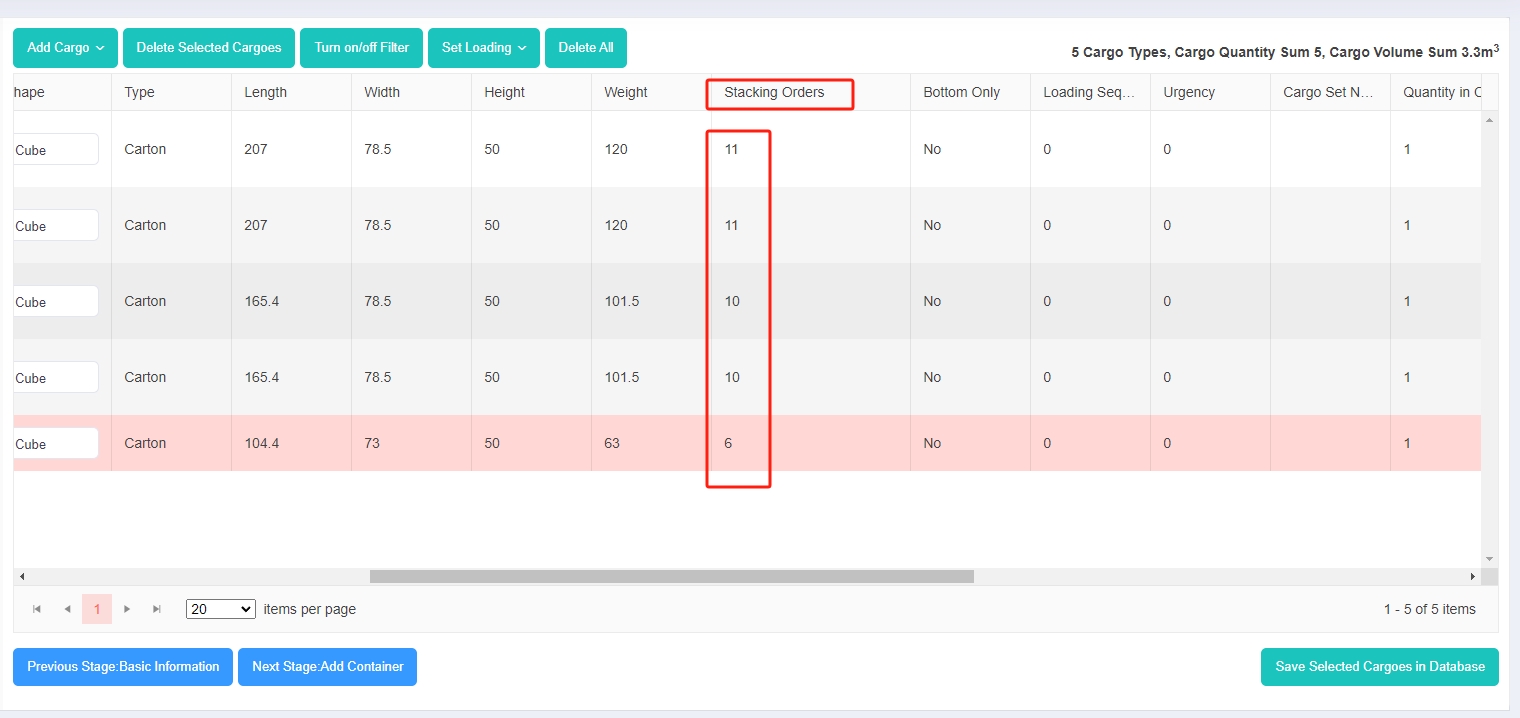

In this scenario, the parameter “Stacking Orders” in the software can meet this requirement well. This parameter indicates the load-bearing capacity of the goods, which is a relative value. The larger the value, the stronger the load-bearing capacity, and the lower it is placed, and vice versa. Stacking Orders can be set according to different standards.

Most of our clients, such as BAIC Motor and FAW Group, often base on the gross weight of each SKU. For example, goods within 100kg belong to one Stacking Orders number, and goods within 100-200kg belong to another. The first is smaller than the second, so it is placed above.

Some clients also set it according to the density of the goods, such as DB Schenker logistics (serving Mercedes-Benz). Setting by packaging material is also feasible. For example, the carrying capacity of palletized cargo is stronger than that of bulk cargo in most cases, so a larger Stacking Orders number can be set to place it lower.

After setting Stacking Orders, the software knows how to define the stacking relationship between different goods, and provides an optimal load plan.

2.Mixed loading of palletized cargo or both palletized cargo and bulk cargo.

In this case, when stacking bulk cargo, the stacking relationship between them can be defined by the Stacking Orders parameter. How to determine the relationship between palletized cargo and that between palletized cargo and bulk cargo?

①If the loading capacity of palletized cargo is similar and stronger than bulk cargo, needing to place it lower.

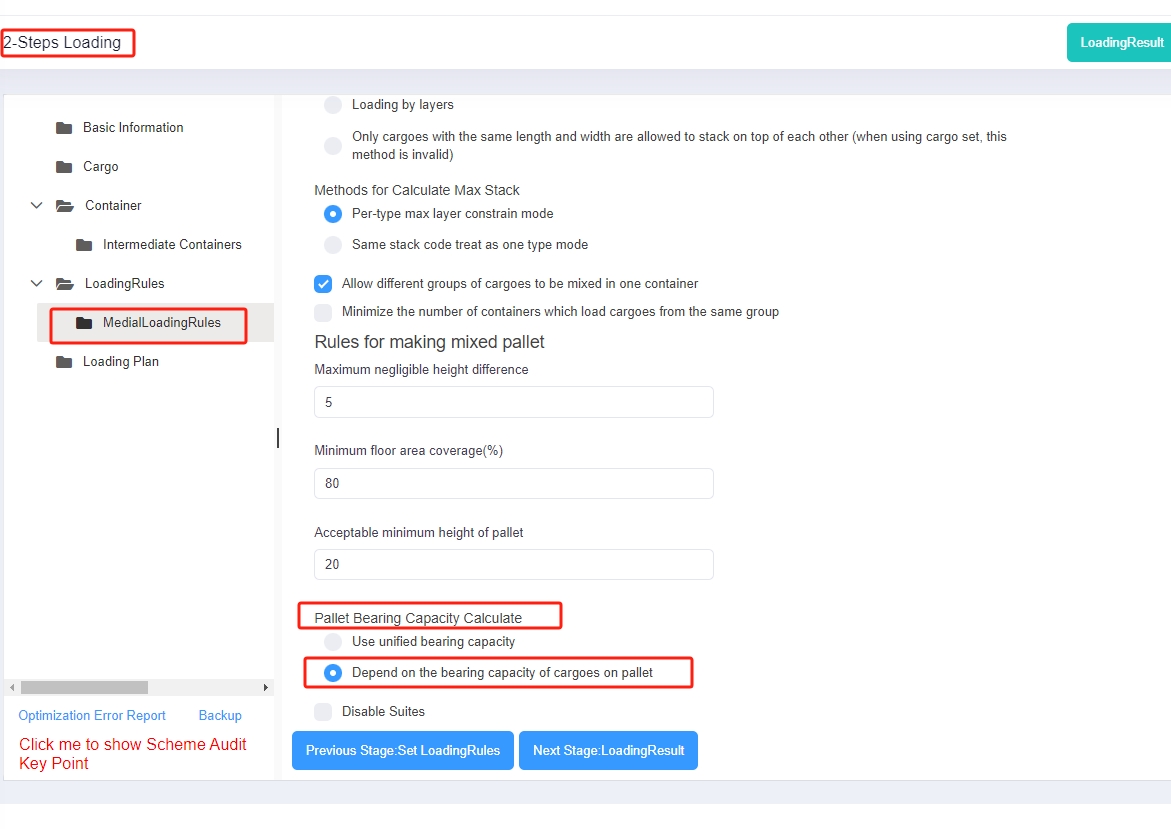

At this time, select the “Medial loading rule-Pallet Bearing Capacity Calculate-Use unified bearing capacity” in the software. By default, the Stacking Orders value of palletized cargo is relatively large, 254, indicating strong load-bearing capacity, so will be placed lower.

②If multiple types of goods are mixed on 1 pallet and the bearing capacity of goods varies, and the carrying capacity of cargo on pallets also needs to be considered when stacking palletized cargo, select “Medial loading rule-Pallet Bearing Capacity Calculate-Depend on the bearing capacity of cargoes on pallet”. Then the Stacking Orders value of the palletized cargo is determined based on the smallest one of the goods loaded on the pallet, for example, the pallet A is loaded with heavy indoor units and light panels, then after the pallet is packed, the Stacking Orders number of the palletized cargo is taken as the that of the panel.

What are the different requirements for stacking goods in your industry or company during cargo transportation? Welcome to discuss! Let’s figure out how to effectively satisfy your requirements together!