Recently, an IT director working for a famous logistics company came to us, hoping to improve their container loading process efficiency with the help of the container loading software. After in-depth discussions with this manager, I knew about some realities about their company’s business processes.

Despite being a globally renowned logistics enterprise, they still rely entirely on manual experience for cargo loading calculation. Their clients come from various industries such as automotive parts, household appliances, furniture, electronics, etc., outsourcing the transportation of goods to these logistics companies, which are responsible for the shipment. However, from conversations with this manager, I learned that even some manager-level staff are largely unaware of the necessary actions during the whole order shipping process, the diffeent stages in the transportation that incur costs, how these costs are precisely calculated, and which costs are controllable.

In short, the whole container allocation and loading process is entirely opaque, non-standardized, uncontrollable, and untraceable. Therefore, cost control can solely rely on the subjective experience of the personnel involved in container allocation and loading. As we know, any process becomes more risky and hazardous when human involvement rate is high. To achieve effective cost reduction and efficiency improvement, it is essential to minimize the subjective and uncontrollable factors introduced by human involvement throughout the entire order delivery process and instead increase the involvement of controllable tools. Ideally, humans should only serve the role of supervision and verification.

Even insiders within logistics companies are unclear about the costs incurred before goods are shipped and which of these costs are controllable, not to mention manufacturing companies who assign this business to them. However, in reality, this process is not as complex as it seems. Let’s take a look together!

For manufacturing companies, their main responsibility lies in production. When their customers make new orders, then they start the whole process to prepare for the delivery. Upon receiving orders, the flow of goods may have two different directions:

Some manufacturing companies are large in scale and have a well-established business system, with independent logistics departments capable of handling the transportation of goods. For them, the entire process from production to delivery to the customer’s hands is controlled by various departments within the company. This process includes receiving orders, arranging production (the sequence of these two stages varies among companies), warehouse sorting, container/truck loading plan calculation, scheduling, transportation, and delivery to the customer. For these companies, understanding the operations of their internal logistics department may be relatively easy and there might be fewer obstacles. However, according to our observation, even these companies have significant room for improvement in terms of internal informatization. Many companies are unaware of the cost composition at various stages, let alone cost control.

Many manufacturing companies are not very large in scale and only focus on production. In such cases, they outsource the transportation of products to professional logistics companies, which then handle the dispatch and transportation of goods. The logistics companies are responsible for container allocation and loading for these products, as well as subsequent scheduling and transportation. Details regarding the subsequent stages such as route optimization will not be elaborated here.

In conclusion, whether manufacturing companies independently control the process or outsource it to logistics companies, from order generation to goods being loaded onto vehicles/containers ready for shipment, there are various operations involved, which incur costs. It is worthwhile for us to delve deeper into understanding which costs are relatively controllable and contribute to the sustainable development of the company.

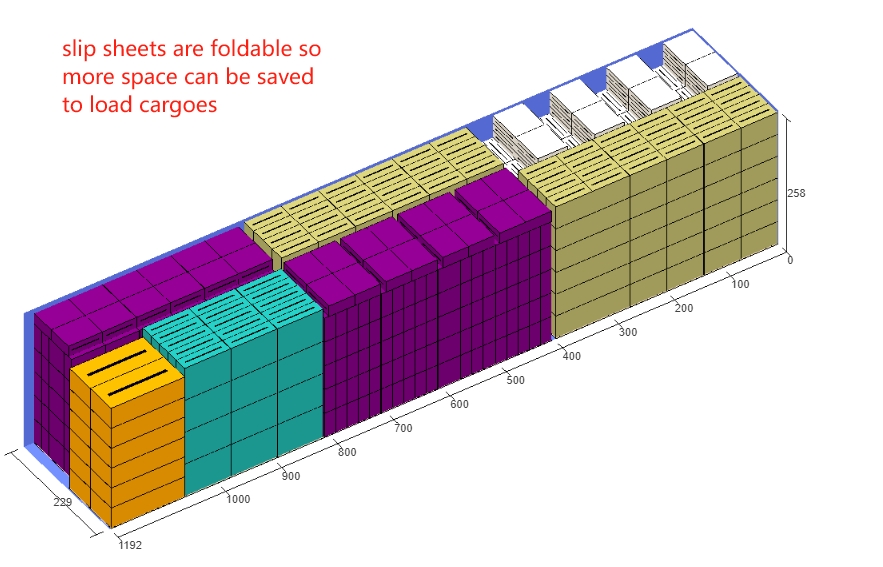

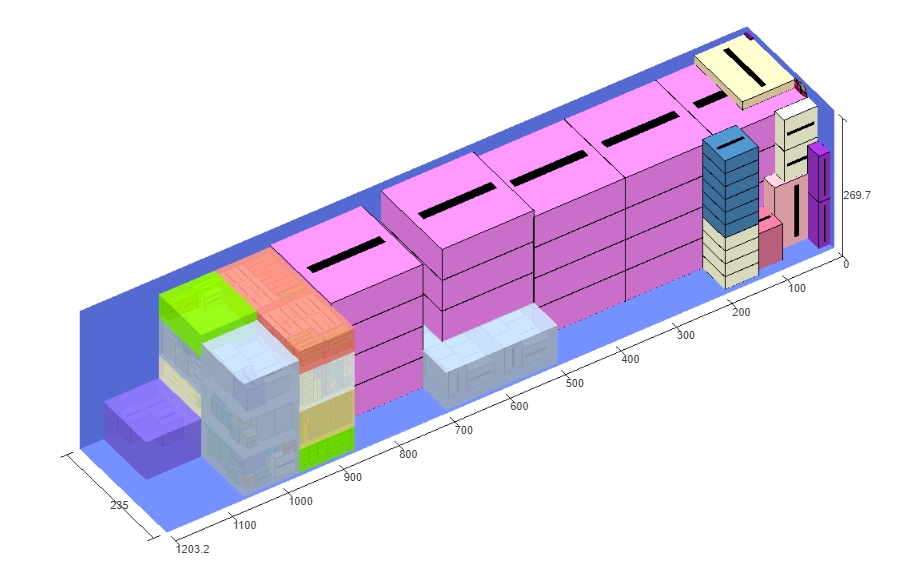

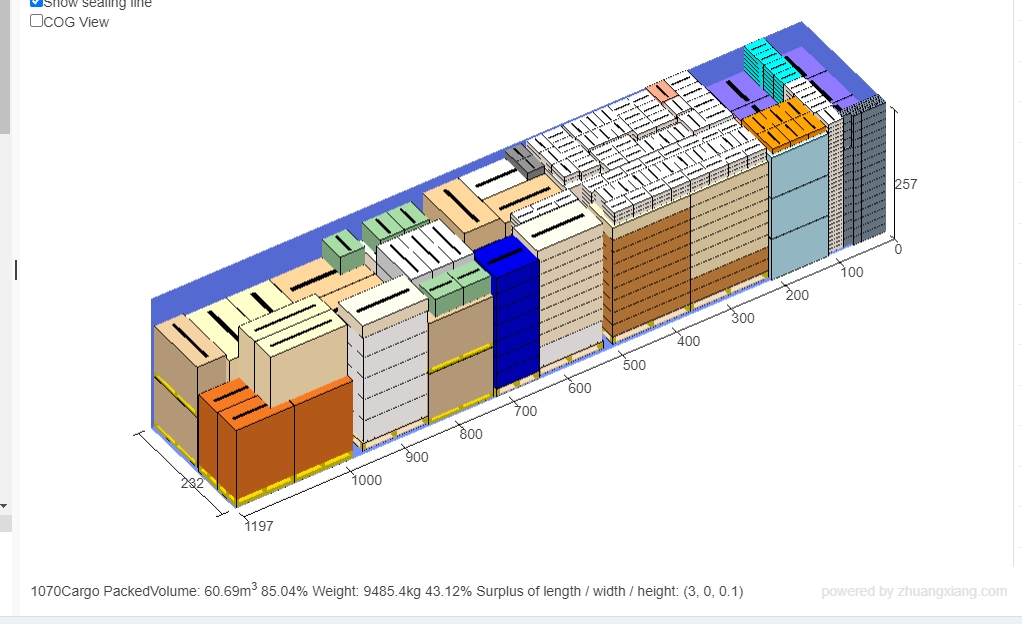

Once a batch of goods is ordered, we need to prepare the goods listed in the order and design how to pack/load them based on safety loading and business rules. Safety loading involves arranging goods in a way that minimizes tilting, shifting, and potential damage during transportation, thus ensuring the integrity of the goods. Business rules refer to the requirements that may arise during cargo handling and transportation. For example, if a batch of goods contains a large quantity of a particular product, it’s preferable to place all those items together in a container rather than dispersing them across different containers or positions within one container. Similarly, if the same batch of goods needs to be delivered to different warehouses, the order of fetching the goods affects how the goods are arranged in the container. Considering such requirements thoroughly before issuing a packing plan ensures that the design is practically feasible and maximizes loading efficiency while minimizing product unit costs.

According to the IT manager of this logistics company, they currently have a department of personnel in charge of loading plan. Upon receiving new orders, they assign goods with the same booking number to the same container whenever possible. Their clients also specify a loading rate requirement for each container just like a KPI standard. Container loading calculation personnel estimate the loading volume based on different requirements and then determine which goods to place in each container based on the volume and dimensions of each item. However, the specific stacking arrangement of goods, such as which items can be stacked on top of others, is currently impossible to determine manually or at least takes a long time to get which, if any cannot ensure the accuracy and feasibility. Instead, the company relies on rough estimations from their manual long-term experience in container loading, which is highly subjective and time-consuming to verify.

- It is impossible to accurately define the stacking relationship between different goods.

- Manual results can only be verified on site. For example, if a customer’s cargo is palletized, the total weight of the goods stacked on top of each pallet and the pallet itself must not exceed the maximum stacking capacity of the bottom palletized cargo. When manually calculating container loading, if the cubic volumeis the only reference to determine which goods to place in the container, it is impossible to directly define the weight distribution between different pallets. It requires deliberate and multiple times of calculation to determine different allocation results for different scenarios. Even if a so-called pattern is obtained through repeated on-site verification in the early stages, considering the diverse range of products in the logistics industry, and the varying types and quantities of products for each container loading, it is impossible for the human brain to analyze and summarize a set of rules for each scenario and remember them. Even if this task is completed with great effort, can the effectiveness of the resulting solution be guaranteed? Can the the output benefits make up for manpower and time costs? These are all hard questions.

In conclusion, when relying entirely on manual power, the subjective and uncontrollable nature of human factors poses the greatest risk to the entire process.

However, now many solutions designed based on manual experience have reached a commendable level, to some extent meeting the requirements and ensuring a certain loading rate, fully validating the capability of the human brain.

However, the time costs of designing such solutions is also significant. If we could leverage some of the rapidly developing high-tech products of today’s era to greatly enhance efficiency while achieving highly optimized results, thereby minimizing the risks brought about by uncontrollable human factors, why not do it? Moreover, not all container loading personnel can reach such a level, and the logic and analysis made earlier are based on the assumption that human power has achieved an ideally high level.

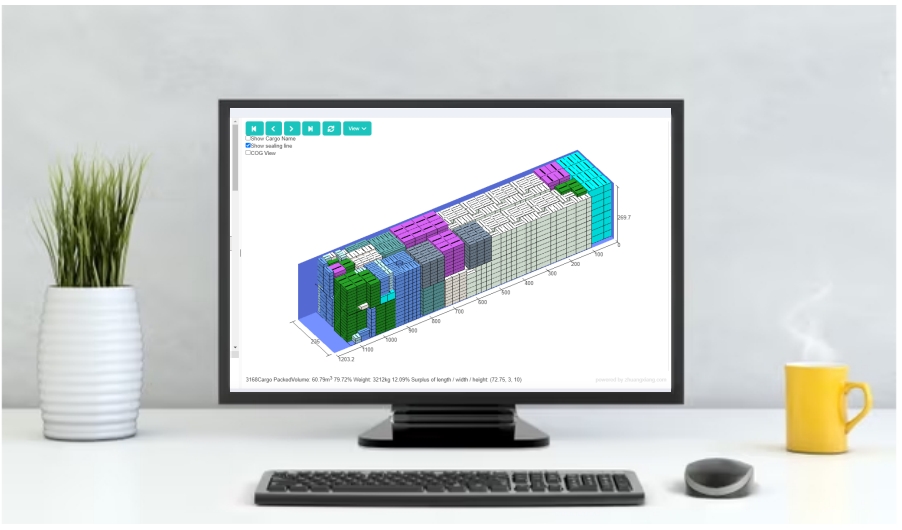

As a leader in the field of intelligent cargo loading software, LoadMaster can effectively help you mitigate various drawbacks that may arise from manual operations, achieving predictable, manageable, and traceable order shipping processes. The standardization and transparency of the entire process can also enable you breathe easy now!

During the order placement phase, you can preliminarily assess the cargo loading based on customer orders using the software. If there is remaining space or only a small amount of cargo is left, you can communicate with the customer to adjust the order quantity, striving to fulfill the container to reduce transportation costs. After confirming the order, set the corresponding parameters and loading rules, calculate a 3D optimization solution that fully meets the loading requirements, and ensures a high loading rate. This plan can also directly tell you how to allocate cargo to different containers in a scientific way. Once the plan is confirmed, you can determine the trucking information and then share it with the on-site container loading department. With clear container loading guidance, the container loading task can be easily and accurately completed. Once the cargo is loaded, it can be shipped to the customer!

In this way, with the assistance of the software, the efficiency and accuracy of the entire process are greatly improved, while the labor and time costs are significantly reduced. In the long run, the competitiveness of the enterprise in the market will surely steadily improve, and the future development of the enterprise is promising!

In any era, those who follow the trend thrive, while those who resist it perish. For us living in the era of technology, perhaps leveraging the dividends brought by technological development is the key for us to stand firm in the tide of the times.

(

(