One of our clients - HONDA-Sundiro bought LoadMaster container loading software, but due to insufficient communication, information asymmetry or any other factor that may affect, they didn’t make the right choice on the software version. They purchased a relatively simple version which is cheaper but then found when operating that it can not fully satisfy all their needs which can only be met by a relatively advanced version, leading to a waste of money, time and labor.

While in the process of requirement communication and confirmation, our staff asked if they have some complicated loading requirements that can only be satisfied by the advanced version and they regarded that they didn’t have that. it’s not only because of the insufficient communication, but different people’s levels of comprehension regarding the same stuff vary, which warns us of the significance of full and thorough communication.

But what is requirement communication? Why is it important to purchasing a load planning software? And how to effectively communicate? Let’s have a look!

Here “requirements” are not only related to the cargo stacking during on-site or transportation, but include all the apparent and potential needs that the company would like to achieve with the help of a 3d load planning software.

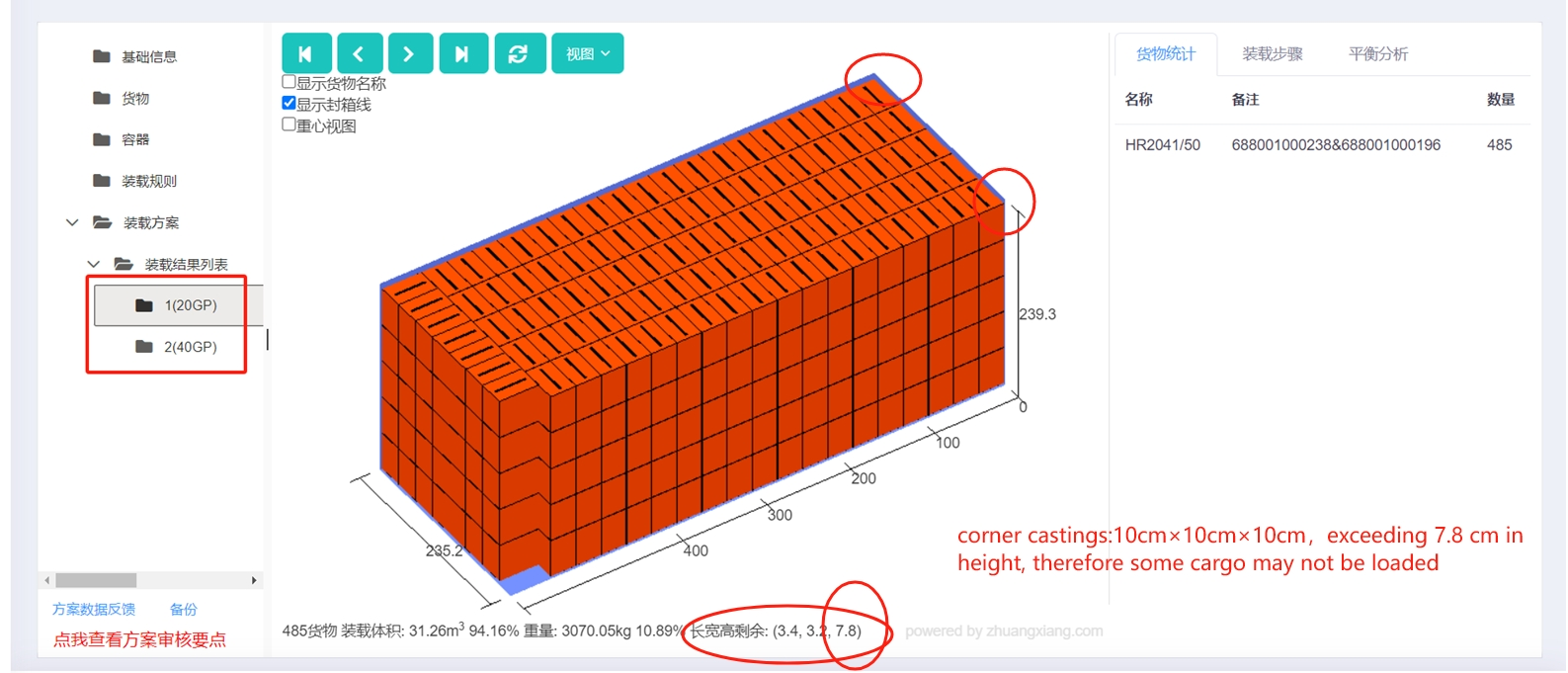

Starting from the actual loading of goods on-site, we hope to achieve accurate loading (for example, ①after reserving space for corner castings in the software, it can automatically avoid them when calculating; ②setting reserved dimensions in the container/trailer can simulate the manual placement gaps and carton expansion during on-site loading) and safe loading (for example, ensuring heavier goods do not press on lighter ones, changing the placement of the cargo near the container door to reduce the possibility of tipping and falling, and limiting the maximum stacking layers according to the bearing capacity of different goods) to prevent or reduce the chances of wrong or missed loading, thus minimizing unnecessary losses.

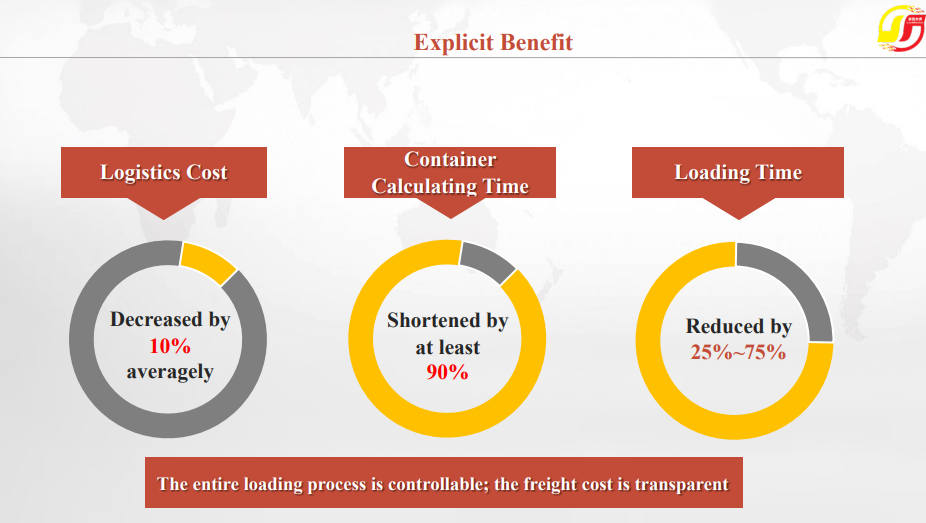

In addition to the specific needs of loading goods into containers/trucks, there are also some potential demands for intelligently choosing the right type of vehicle, container, pallet, thus selecting the most economical combination, whether the software-designed loading rate can be higher than manual calculation, thus reducing transportation costs.

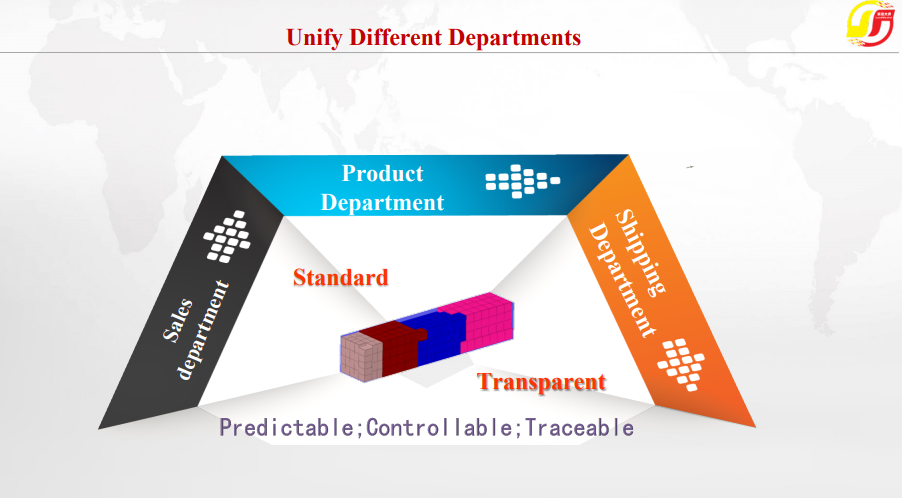

Looking at “requirements” in a more broad view, after using the software, can the efficiency of communication between departments be improved (some companies experience conflicts between departments before using software due to the lack of clear 3D diagrams), can employee work efficiency be improved (with the help of software to quickly produce accurate schemes, the saved time can be used for more important managerial work), and can the communication efficiency with customers be improved (after seeing the clear 3D diagrams, customers can know how their goods are loaded, which will increase satisfaction and strengthen customer loyalty)? These needs play a crucial role in the company’s future development.

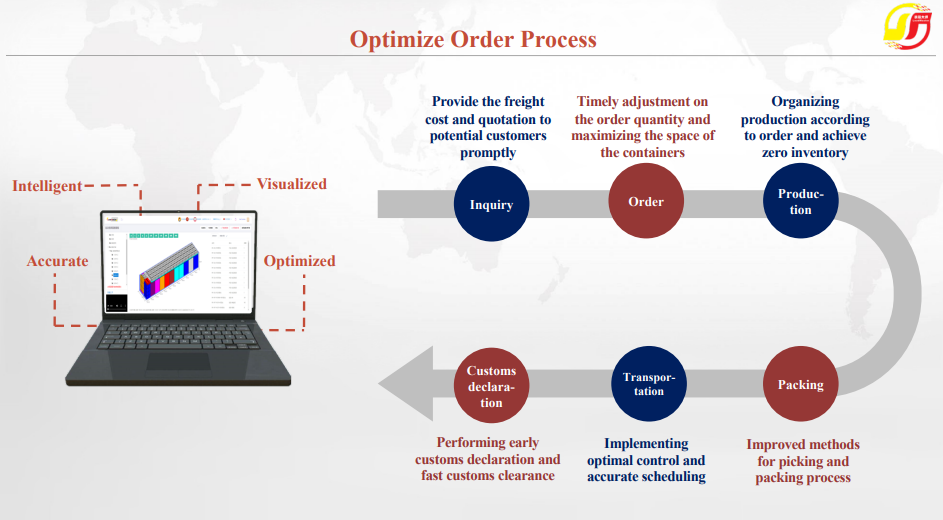

Looking at the entire process, the load planning software has helped starting from the customer’s order placement. The company’s front-end sales staff can use the software to produce clear 3D diagrams, Check with the customer whether the container space is fully utilized, and if not, negotiate to increase the order to try to fill the container and reduce sea freight costs, especially at a time when sea freight costs are rising, its significance is self-evident. After confirming the order with the customer, the logistics department can then accurately arrange for container/truck, then sort the goods in advance, and refer to the software’s step diagrams to achieve accurate and safe loading. After the goods are loaded, customs declaration materials can be prepared in advance for customs declaration, where the software’s packing list reports are useful again. Then the goods are transported and finally reach the customer safely and on time.

Throughout the process, from the initial communication of orders, to designing how to load the goods into the container, to safe and accurate loading, both the buyer and seller can clearly understand the whereabouts of the goods, and also clearly know at which stage they can try to reduce costs and increase efficiency, achieving a predictable, controllable, and traceable order shipping process, which undoubtedly plays a “wave-boosting” role in the sustainable development of the enterprise.

And all these ultimately are based on thorough and comprehensive communication of needs at the early stage. Only by understanding what each enterprise wants can we tell you how the software can help you. And this requires not only our effort but also your full trust and support.

Do you want to thoroughly know about your companies’ need sand learn how much costs can be saved for your future development? Welcome to try our loading requirement sorting service (http://loadmaster.biz) to help you better understand your business and recognize how and where you can make some improvement!