In the logistics and transportation industry, the efficiency of container loading directly impacts transportation costs and the safety of the cargo. A common misconception is that a fully loaded container equates to more cargo being loaded. However, this is not always the case. This article will explore why loading a container to its apparent full capacity does not necessarily mean loading more cargo and how to optimize container loading to achieve maximum transportation efficiency.

- Load Full vs. Load More: Definitions and Differences

Loading full typically means that the container’s space is filled as much as possible, with no visible gaps. However, loading more refers to loading as much cargo as possible within the limited space, not just filling it up but effectively utilizing every inch of space to increase the quantity of the cargo.

- Space Utilization and Loading Strategies

- 𝗠𝗮𝘁𝗰𝗵𝗶𝗻𝗴 𝗦𝗵𝗮𝗽𝗲𝘀 𝗮𝗻𝗱 𝗦𝗶𝘇𝗲𝘀: Different sizes and shapes of goods need to be reasonably matched during loading to reduce gaps. For example, LoadMaster container loading software’s “stacking products with similar or identical dimensions” can improve space utilization.

- 𝗕𝗮𝘀𝗲 𝗔𝗿𝗲𝗮 𝗢𝘃𝗲𝗿𝗹𝗮𝗽: High overlap rates can increase stacking stability, reduce the risk of sliding and shifting, and help better utilize vertical space.

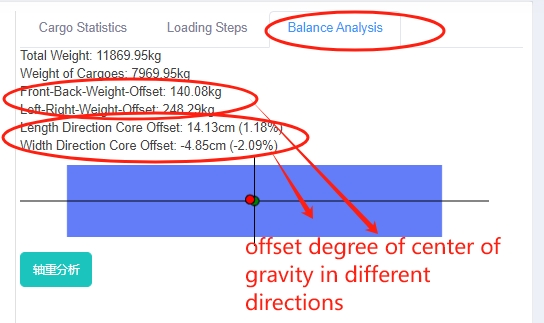

- Center of Gravity and Stability

When loading, it’s not just about the quantity but also the center of gravity and stability of the cargo. An uneven center of gravity can cause the cargo to tilt or even collapse during transportation, increasing the risk of damage. Therefore, a reasonable loading strategy should ensure an even distribution of the center of gravity to maintain cargo stability. LoadMaster container loading software’s 3d cargo loading plan provides a thorough and scientific balance analysis by referring to the standards of both maritime shipping and railway transport.

- Loading Equipment and Technology

In modern logistics, the application of loading equipment and technology is also crucial. For example, using professional container loading software like LoadMaster can create the best loading plan, ensuring that more cargo is loaded while maintaining stability. Additionally, intelligent 3d loading solutions can improve loading efficiency and reduce human error.

- Transportation Safety and Compliance

Loading more does not mean ignoring safety and compliance. Overloading or unreasonable loading methods not only violate transportation regulations but can also lead to serious safety hazards. Therefore, while aiming to load more, it is essential to ensure that the loading methods comply with relevant regulations to ensure transportation safety.

- Customer Case: Practical Application of Optimized Loading

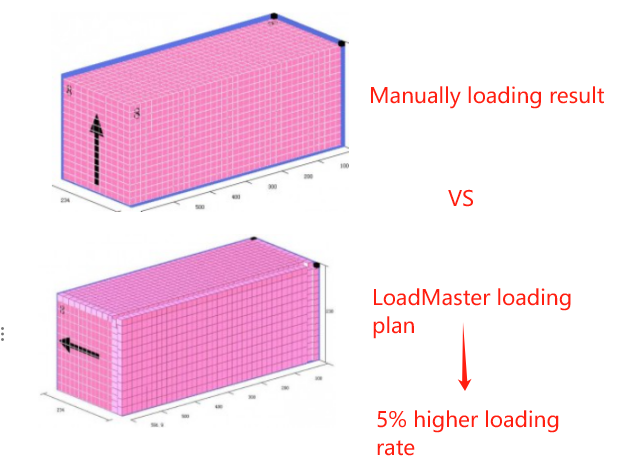

A customer had a batch of goods to be shipped to Africa, but the shipping costs had recently tripled. They loaded the containers manually and left out more than 70 boxes. If the excluded goods were to be shipped separately, it would cost an additional 10,000 RMB, and they might not even find available containers, leaving air freight as the only option, which is even more expensive. However, their loading workers said, “We have already loaded it to the full, there are no gaps.”

In reality, 𝘁𝗵𝗲 𝗰𝗼𝗺𝗯𝗶𝗻𝗮𝘁𝗶𝗼𝗻 𝗼𝗳 𝗱𝗶𝗳𝗳𝗲𝗿𝗲𝗻𝘁 𝗽𝗹𝗮𝗰𝗲𝗺𝗲𝗻𝘁 𝗺𝗲𝘁𝗵𝗼𝗱𝘀 𝘄𝗶𝘁𝗵𝗶𝗻 𝘁𝗵𝗲 𝗰𝗼𝗻𝘁𝗮𝗶𝗻𝗲𝗿 𝗶𝘀 𝗮 𝗵𝗶𝗴𝗵𝗹𝘆 𝗰𝗼𝗺𝗽𝗹𝗲𝘅 𝗺𝗮𝘁𝗵𝗲𝗺𝗮𝘁𝗶𝗰𝗮𝗹 𝗽𝗿𝗼𝗯𝗹𝗲𝗺, 𝗯𝗲𝘆𝗼𝗻𝗱 𝗵𝘂𝗺𝗮𝗻 𝗰𝗮𝗹𝗰𝘂𝗹𝗮𝘁𝗶𝗼𝗻 𝗰𝗮𝗽𝗮𝗯𝗶𝗹𝗶𝘁𝗶𝗲𝘀. By using professional loading software, they found that different placement combinations could fit all the goods into the containers. 𝗟𝗼𝗮𝗱𝗠𝗮𝘀𝘁𝗲𝗿 𝗰𝗼𝗻𝘁𝗮𝗶𝗻𝗲𝗿 𝗹𝗼𝗮𝗱𝗶𝗻𝗴 𝘀𝗼𝗳𝘁𝘄𝗮𝗿𝗲 𝗰𝗮𝗹𝗰𝘂𝗹𝗮𝘁𝗲𝗱 𝘁𝗵𝗶𝘀 𝘀𝗼𝗹𝘂𝘁𝗶𝗼𝗻 𝗳𝗼𝗿 𝗼𝗻𝗹𝘆 𝟲 𝗥𝗠𝗕, 𝘀𝗮𝘃𝗶𝗻𝗴 𝗼𝘃𝗲𝗿 𝟭𝟬,𝟬𝟬𝟬 𝗥𝗠𝗕 𝗶𝗻 𝗮𝗱𝗱𝗶𝘁𝗶𝗼𝗻𝗮𝗹 𝗰𝗼𝘀𝘁𝘀. It was incredibly worthwhile!

- Conclusion

When loading containers, loading full does not equate to loading more. An effective loading strategy should consider various factors, including space utilization, center of gravity and stability, loading equipment and technology, and transportation safety and compliance. Through scientifically reasonable loading plans, it is possible to achieve loading more, loading stably, and loading safely, thereby maximizing transportation efficiency and reducing logistics costs.

In the future of logistics and transportation, with continuous technological advancements and the application of optimized loading plans, we believe we can more efficiently utilize container space, achieving higher loading efficiency and lower transportation costs.