In today’s fiercely competitive automotive parts industry, improving logistics efficiency has become a key factor for companies to gain a competitive edge. Auto parts logistics mainly includes three aspects: inbound logistics, outbound logistics, and spare parts logistics. Each stage requires precise management and optimization. As a highly efficient container optimization tool, the 𝗟𝗼𝗮𝗱𝗠𝗮𝘀𝘁𝗲𝗿 container loading software provides strong support for every stage of auto parts logistics.

Let’s have a closer look at Inbound Logistics!

𝟭. 𝗜𝗻𝗯𝗼𝘂𝗻𝗱 𝗟𝗼𝗴𝗶𝘀𝘁𝗶𝗰𝘀: 𝗢𝗽𝘁𝗶𝗺𝗶𝘇𝗶𝗻𝗴 𝘁𝗵𝗲 𝗧𝗿𝗮𝗻𝘀𝗽𝗼𝗿𝘁𝗮𝘁𝗶𝗼𝗻 𝗼𝗳 𝗥𝗮𝘄 𝗠𝗮𝘁𝗲𝗿𝗶𝗮𝗹𝘀 𝗮𝗻𝗱 𝗖𝗼𝗺𝗽𝗼𝗻𝗲𝗻𝘁𝘀

Inbound logistics refers to the transportation of raw materials, components, and other production necessities from suppliers to the automobile manufacturing plant. The goal of this stage is to ensure the continuous operation of the production line and the timely supply of materials. Specifically, it includes:

- Raw Material Transportation: Transporting raw materials from suppliers to the manufacturing plant.

- Component Distribution: Delivering various components to the respective production workshops.

- Warehouse Management: Managing the storage and sorting of inbound materials.

𝗪𝗵𝗮𝘁 𝗔𝗿𝗲 𝘁𝗵𝗲 𝗡𝗼𝘁𝗮𝗯𝗹𝗲 𝗖𝗵𝗮𝗿𝗮𝗰𝘁𝗲𝗿𝗶𝘀𝘁𝗶𝗰𝘀 𝗼𝗳 𝗜𝗻𝗯𝗼𝘂𝗻𝗱 𝗟𝗼𝗴𝗶𝘀𝘁𝗶𝗰𝘀?

High Frequency and Small Batches

Inbound logistics typically involves high-frequency, small-batch transportation to ensure continuous supply to the production line. This model can reduce inventory pressure but also requires the logistics process to be highly flexible and responsive.Precise Time Management

Inbound logistics emphasizes 𝗝𝘂𝘀𝘁-𝗜𝗻-𝗧𝗶𝗺𝗲 (𝗝𝗜𝗧) management, requiring materials to arrive precisely when needed for production. This management approach can reduce inventory costs but demands a high level of time control in logistics.Diverse Material Types

Inbound logistics involves various types of materials, including raw materials, components, auxiliary materials, and other production necessities. These materials vary in volume, weight, and shape, necessitating targeted containerization and transportation planning.

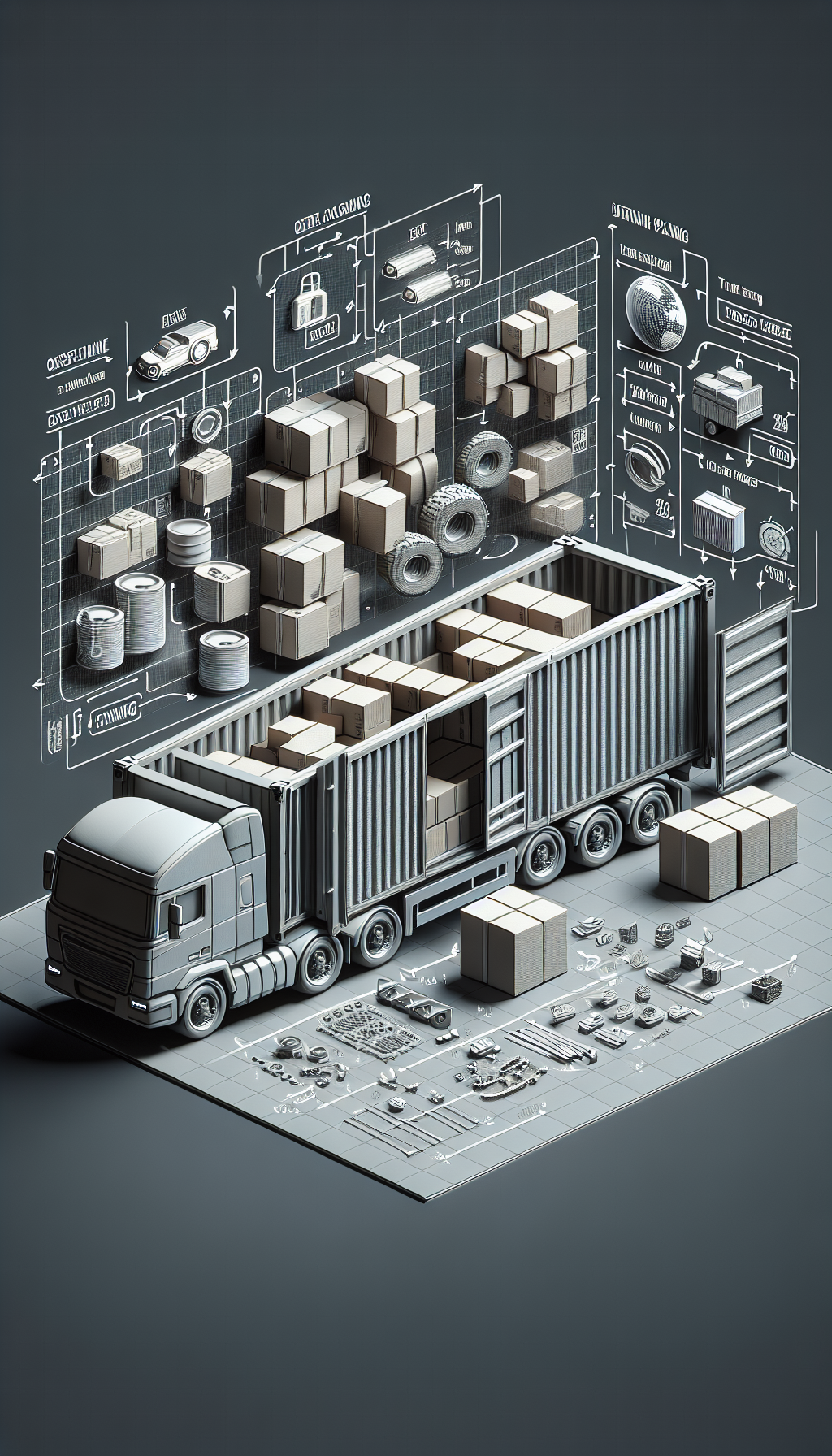

𝗛𝗼𝘄 𝗰𝗮𝗻 𝗟𝗼𝗮𝗱𝗠𝗮𝘀𝘁𝗲𝗿 𝗰𝗼𝗻𝘁𝗮𝗶𝗻𝗲𝗿 𝗹𝗼𝗮𝗱𝗶𝗻𝗴 𝘀𝗼𝗳𝘁𝘄𝗮𝗿𝗲 𝗲𝗻𝗵𝗮𝗻𝗰𝗲 𝗜𝗻𝗯𝗼𝘂𝗻𝗱 𝗟𝗼𝗴𝗶𝘀𝘁𝗶𝗰𝘀 𝗲𝗳𝗳𝗶𝗰𝗶𝗲𝗻𝗰𝘆?

- Intelligent Container Planning: The software can automatically generate the optimal containerization plan based on the volume, weight, and shape of the materials, maximizing the use of transportation space and reducing transportation costs.

- Real-time Data Analysis: By analyzing transportation data in real-time, the software helps companies adjust containerization plans promptly, avoiding production halts due to transportation delays.

- Reduced Losses: Optimized containerization plans can reduce material losses during transportation, ensuring that components arrive at the production line in perfect condition.

𝗖𝘂𝘀𝘁𝗼𝗺𝗲𝗿 𝗖𝗮𝘀𝗲 𝗦𝘁𝘂𝗱𝘆:

Global International Freight Forwarding (China) Co., Ltd., a subsidiary of the Fortune 500 DB Logistics, is a world-leading logistics company providing integrated services including sea, air, and land transportation as well as contract logistics.

Business Background:

Among the company’s numerous clients, industrial and automotive clients’ inbound logistics are characterized by a wide variety of materials and diverse packaging sizes. Often, a single truck needs to load dozens of different types of goods. Additionally, in less-than-truckload (LTL) transportation, the complexity of dry-line goods, mixed with heavy and bulky items, presents a challenge that manual calculations can no longer adequately address.

With the Help of the Container Master Software:

- Loading Efficiency: The time required for manual calculations has been reduced from one hour to 15 minutes.

- System Maintenance: By maintaining the master data within the system, the daily scheduling workload has been significantly reduced.

- 3D Loading Diagrams: The exported 3D loading diagrams can be handed over to our drivers to guide on-site containerization, reducing uncertainties in on-site operations. Additionally, a QR code for each container facilitates simultaneous loading operations for multiple vehicles.

After collaborating with the LoadMaster load planning software, our costs have significantly decreased, and our efficiency has greatly improved, enhancing our market competitiveness. Especially in the current economic downturn, leveraging the software to reduce costs and increase efficiency is beneficial for our long-term development.

This blog post aims to provide insights into the critical role of inbound logistics in the auto parts industry and how advanced tools like the LoadMaster container loading software can drive efficiency and competitiveness. Stay tuned for more insights into outbound and spare parts logistics in the upcoming parts of this series.