The year of 2023 is witnessing a slowdown in global economy and a fiercer competition in international trade. Under such circumstance how to win a potential buyer as fast as possible becomes trickier than before. If you’re working in the foreign trade industry, you must be familiar with the following scenario. An international buyer intends to place an order and makes a specific inquiry, there are a large number of details to consider to close the deal, such as how to quickly provide an accurate quotation to the buyer as well as how to maximally utilize the container to reduce freight costs and increase orders. These details are exactly what the clients of LoadMaster container loading software, pay much attention to.

This is a full container stuffed with cargo.

This is a full container stuffed with cargo.

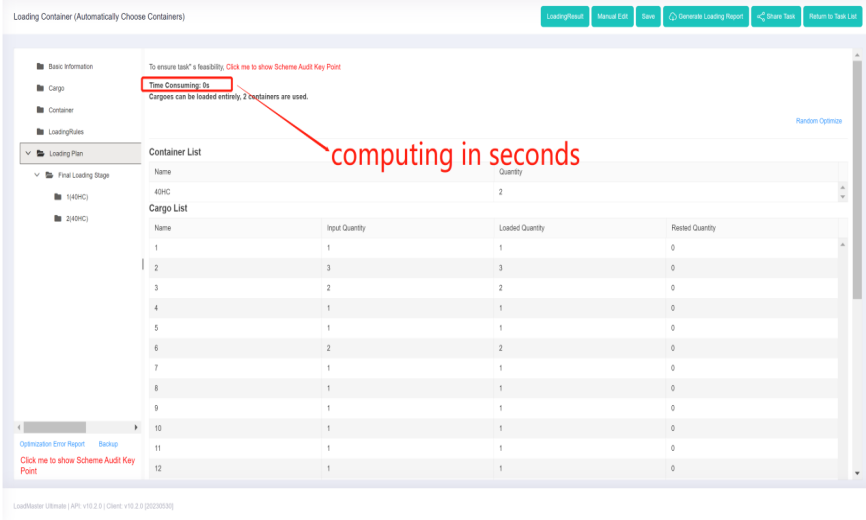

One of the clients from electromechanical industry served by LoadMaster container loading software shares that when a potential buyer makes a specific inquiry on an order, they need to know how many containers are going to be used and which types of container loading are the most suitable. However, there are 1000 SKUs in this order, and each SKU takes up a volume ranging from 1.5-18 CBM, making it extremely difficult to calculate even in a whole week. Without an accurate container load plan, they don’t know corresponding freight costs and quotation, resulting in an increasing risk of losing this buyer. But with the help of LoadMaster container loading software, an accurate container load plan can come out in as short as 10 minutes. (Although the calculation speed of our algorithm is in seconds, the manual edit designed to meet some special container loading demands would take a bit longer for about 10 minutes.) In this way, a potential buyer can be earned as fast as possible.

This is a 3d load plan computing in seconds.

This is a 3d load plan computing in seconds.

Born in 2007, LoadMaster is a container loading software capable of providing intelligent and optimized container load plans to load various cargoes and to achieve palletization and container loading at the same time as a whole.

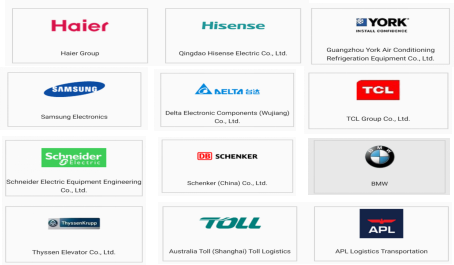

Until now, LoadMaster container loading software has earned a huge customer base of over 400 well-known enterprises in 30 different industries including Haier, Hisense, TCL, Samsung, Delta Power Solutions, Thyssen Elevators, Mercedes-Benz, BMW, Volvo, Tesla, Schneider Electric, MOEN, TOTO, Alstom, TRANE, YORK VRF, DAIKIN GLOBAL, BATELONG, DB SCHENKER, Toll Group, APL, and other transnational corporations. Feedback from these renowned enterprises will be released soon, please stay tuned.

This is a picture of famous clients’ logos.

This is a picture of famous clients’ logos.

Now you may wonder, why has the LoadMaster container loading software earned such a great number of followers? And I’m sure that you can figure it out in the following text.

- LoadMaster container loading software can assist sales executives to calculate how many containers are going to be used and which types of container loading are the most suitable. Since the container loading calculation speed is quite fast, the working efficiency of calculation for sales executives can be increased to more than 90%, improving the communication efficiency on the container quantities and types needed with clients.

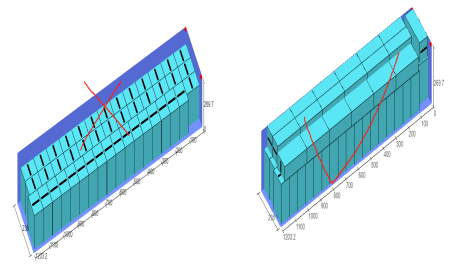

- LoadMaster container loading software has one of the world’s leading load optimization algorithms, which can increase the container utilization rate by 5%-25% and decrease logistics costs.

This is a comparison between a not-full container and full container.

This is a comparison between a not-full container and full container.

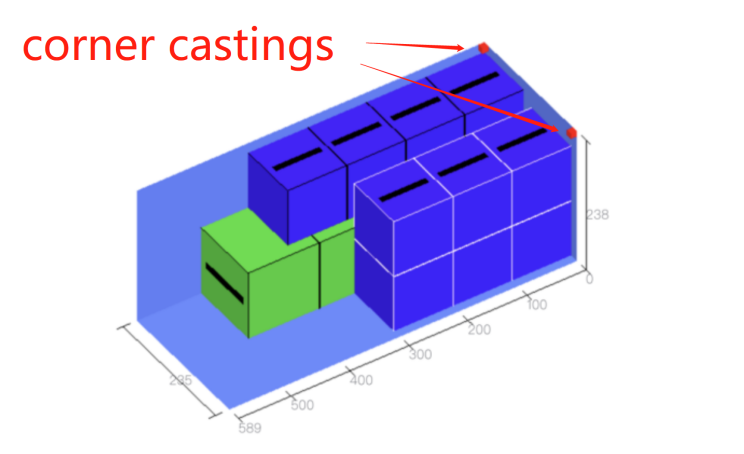

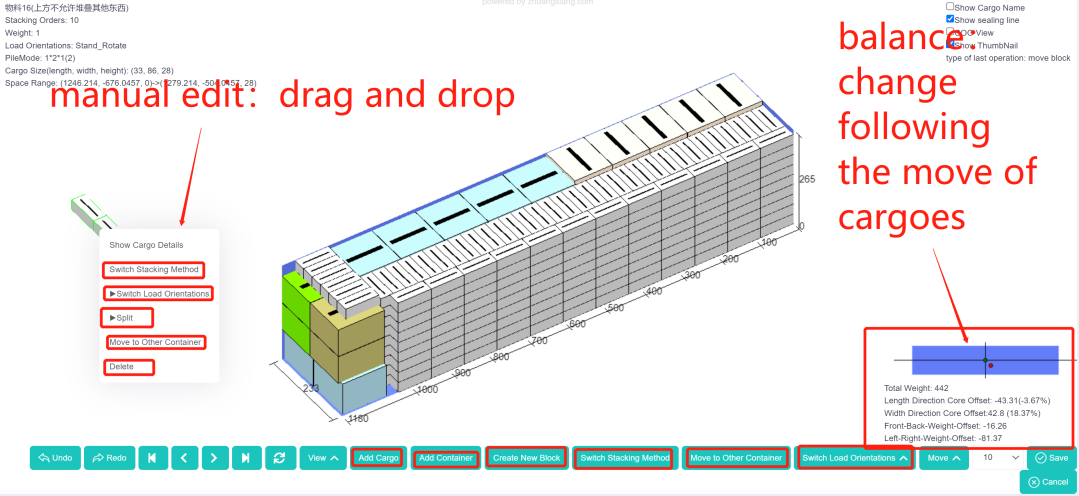

- LoadMaster container loading software facilitates accurate container loading by taking the following details into consideration. For instance, it can automatically avoid corner castings, simulate carton expansion and spatial separation, and reserve the space for forklift operation in the case of container loading with palletized cargoes. The safety demand are considered by LoadMaster when stacking various cargoes and adjusting balance of containers. And this demand can also be met when setting different stacking codes for the same cargo. For example, fridges are normally better be placed with their height vertical to the container ground. However, under the prerequisite of maximally utilizing container space, placing the air conditioners on top of the bottom layer (Since fridges are usually very tall and the remained space in the direction of container height are not enough to place another layer of fridges with the same stacking code but enough for another layer with different stacking codes.) with their height parallel to container ground can also meet the safety demand. In addition, the manual edit is designed to meet users’ special container loading demands and the 3D container loading diagram can be conveniently shared to mobile platforms such as pad and cellphone to guide on-site loading. All these functions of LoadMaster container loading software make accurate container loading a reality.

This is a picture of corner castings.

This is a picture of corner castings.

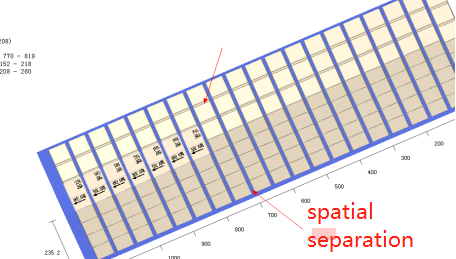

This is a picture of spatial separation.

This is a picture of spatial separation.

This is manual edit interface.

This is manual edit interface.

Finally, LoadMaster container loading software provides a 30-day-long free trial with all functions available together with free customer services of shipping container loading demand analysis and remote presentation training but without times limit. Welcome to apply for our free trial! The free trial URL is http://loadmaster.biz. Please contact us through email if you have any question, and our email address is sales@zhuangxiang.com.

This is the interface of applying for free trial.

This is the interface of applying for free trial.