In today’s era, with the rapid advancement of technology, “intelligence” is no longer a new phenomenon, having permeated into various industries and fields of societal development. The intelligence of the logistics industry has also become an undeniable trend. In recent years, governments around the world have been pushing for the internetization of logistics platforms, and businesses are increasingly focusing on utilizing powerful load planning software to optimize container loading and packing operations, aiming to improve overall transportation efficiency, reduce costs, and achieve standardized and visual management of the entire order shipping process.

However, the myriad of load planning software available in the market has left businesses feeling perplexed when it comes to selection. How can one accurately choose high-quality software that meets their specific needs and avoid making the wrong choice? This article will delve into the industry perspective to provide you with precise strategies and recommendations for selecting load planning software for reference.

𝟭. 𝗜𝗿𝗿𝗲𝘀𝗶𝘀𝘁𝗶𝗯𝗹𝗲 𝗧𝗿𝗲𝗻𝗱 𝗼𝗳 𝗟𝗼𝗴𝗶𝘀𝘁𝗶𝗰𝘀 𝗜𝗻𝘁𝗲𝗹𝗹𝗶𝗴𝗲𝗻𝗰𝗲

With the rapid development of information technology and the continuous growth of the global economy, the logistics industry, and indeed the entire supply chain across various industries, is undergoing an unprecedented transformation. Intelligence has become an inevitable trend for the future development of logistics and the supply chain, with examples from global giants like Walmart and Amazon providing excellent benchmarks for global supply chain intelligence and logistics intelligence. In recent years, governments worldwide have also introduced encouraging policies to promote the development of “Internet+” logistics platforms by supporting logistics companies in digitizing scenarios such as transportation, warehousing, and distribution to cope with the growing demand for logistics and improve overall transportation efficiency.

𝟮. 𝗣𝗮𝗰𝗸𝗶𝗻𝗴 𝗢𝗽𝘁𝗶𝗺𝗶𝘇𝗮𝘁𝗶𝗼𝗻 - 𝗞𝗲𝘆 𝗖𝗼𝗺𝗽𝗼𝗻𝗲𝗻𝘁 𝗼𝗳 𝗟𝗼𝗴𝗶𝘀𝘁𝗶𝗰𝘀 𝗜𝗻𝘁𝗲𝗹𝗹𝗶𝗴𝗲𝗻𝗰𝗲

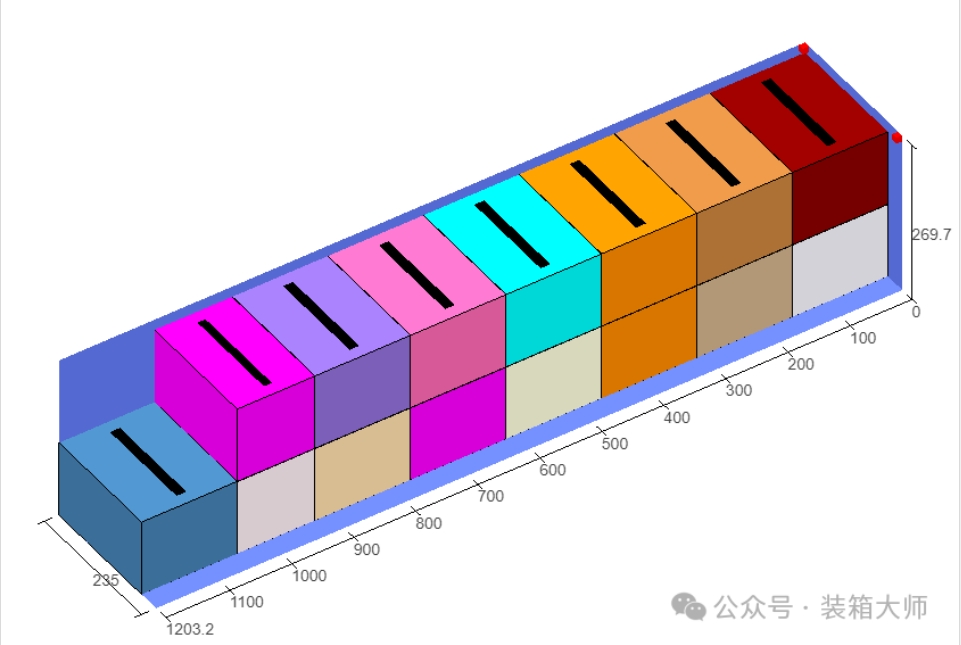

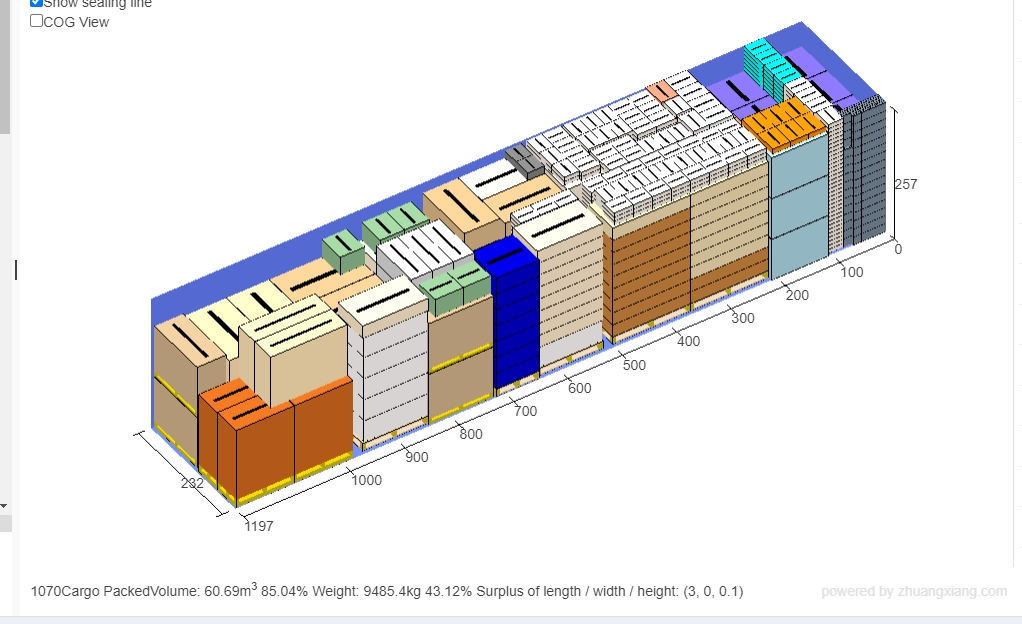

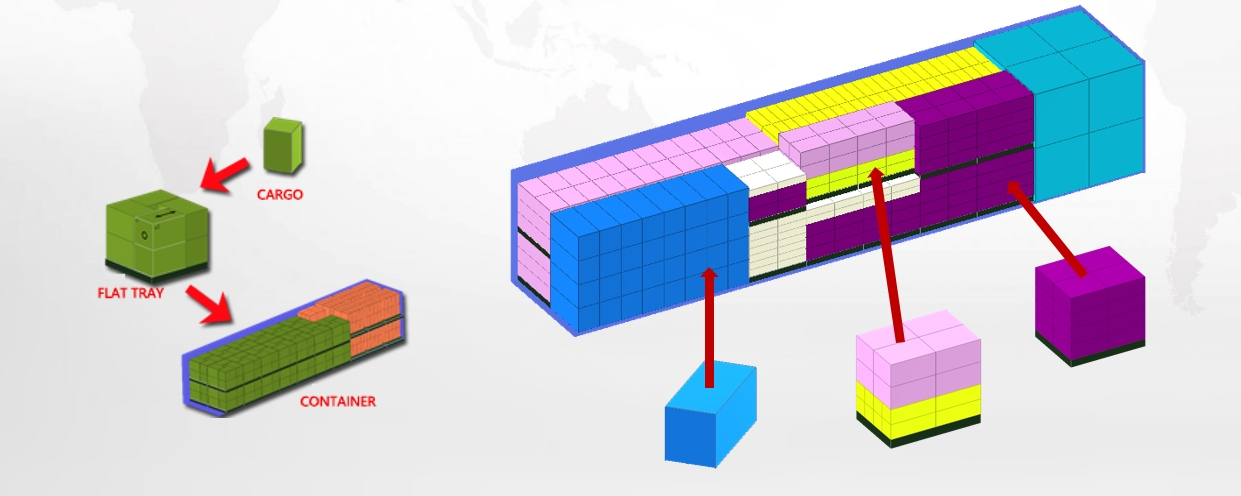

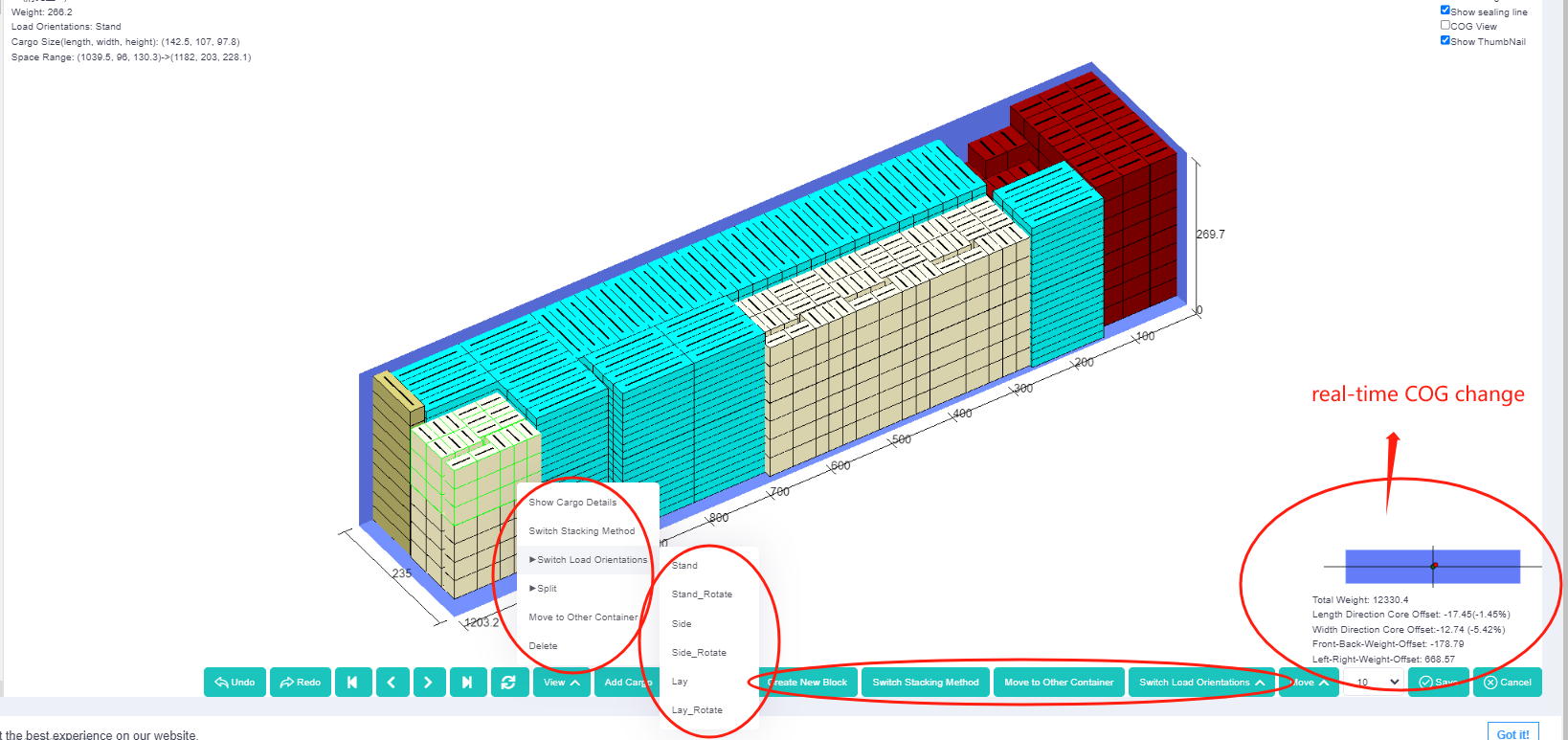

Goods transportation is an integral part of the logistics process, and optimizing container loading and packing operations through load planning software is an essential aspect of realizing logistics intelligence. Choosing high-quality load planning software that truly meets the needs of the enterprise and brings about efficiency improvements can empower companies to achieve predictability, manageability, and traceability throughout the entire order shipping process, thereby enhancing transportation efficiency, reducing costs, and significantly improving market competitiveness.

𝟯. 𝗛𝗼𝘄 𝘁𝗼 𝗔𝘃𝗼𝗶𝗱 𝗪𝗿𝗼𝗻𝗴 𝗖𝗵𝗼𝗶𝗰𝗲𝘀?

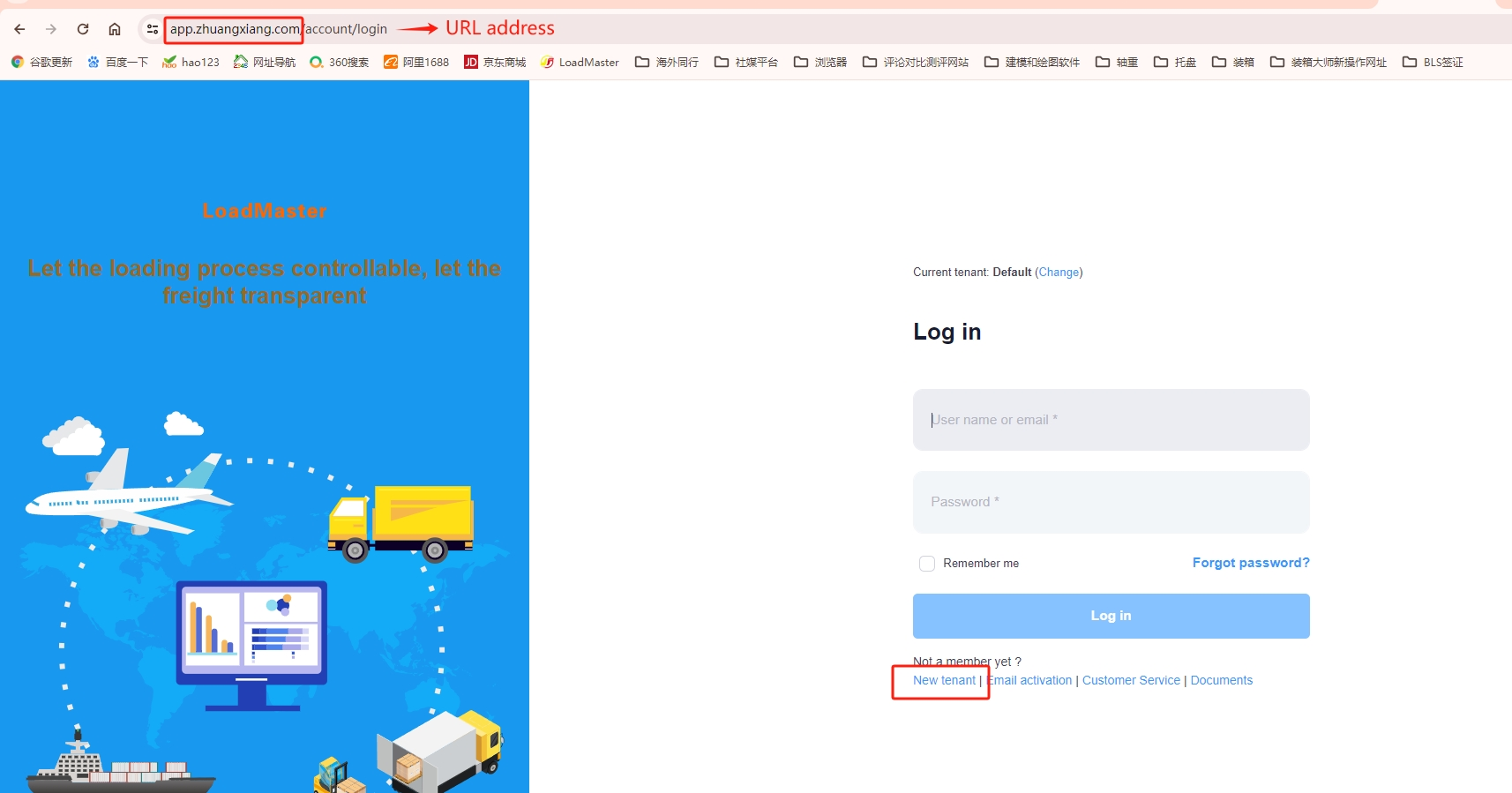

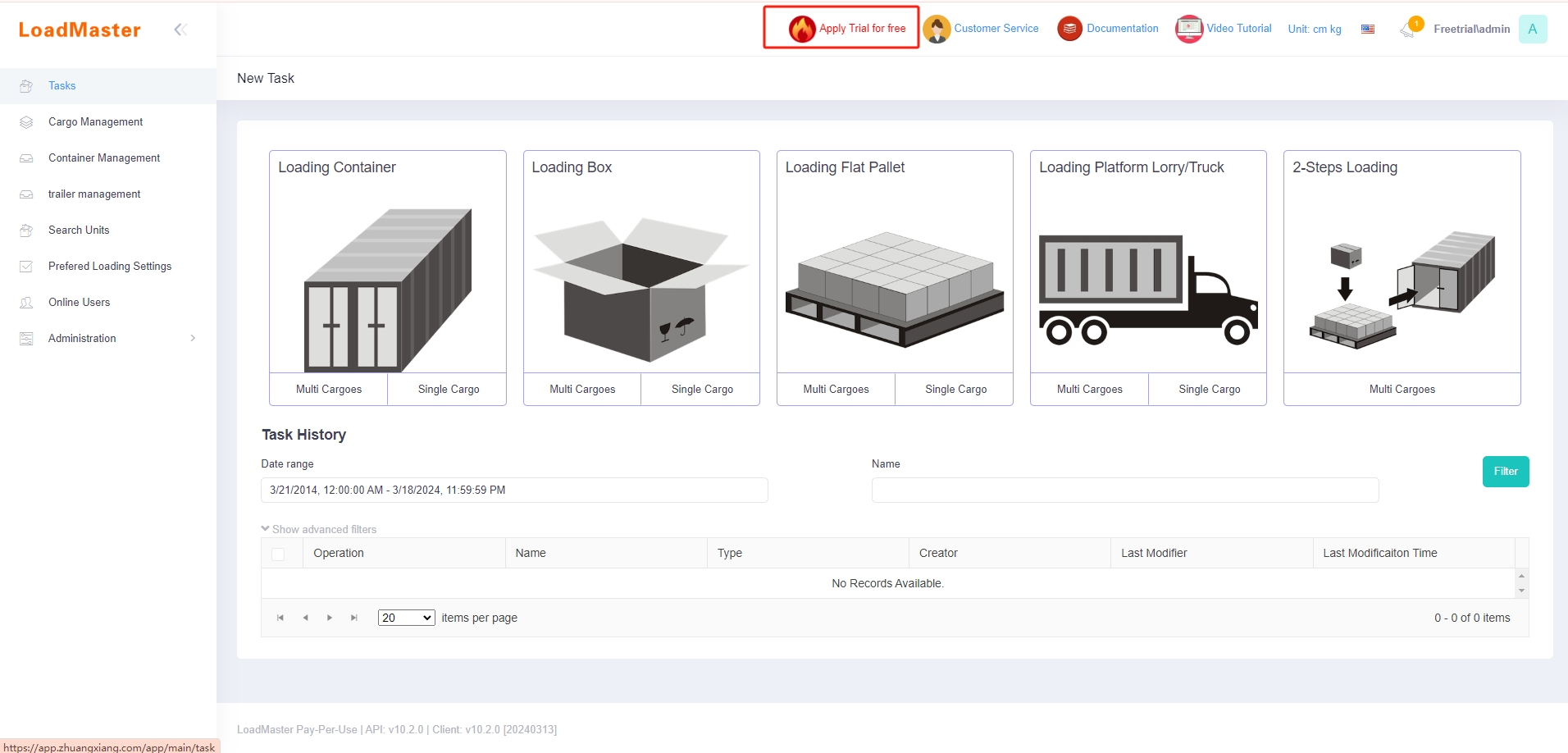

Selecting the most suitable load planning software from the multitude available is no easy task, as a slight oversight can lead to pitfalls and setbacks. It requires comprehensive consideration from multiple perspectives. What details should be noted? Let’s take a look at the suggestions provided by LoadMaster load planning software!

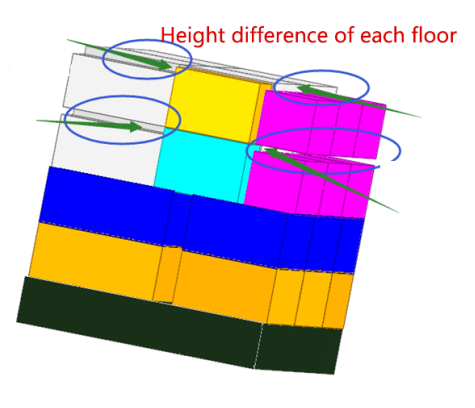

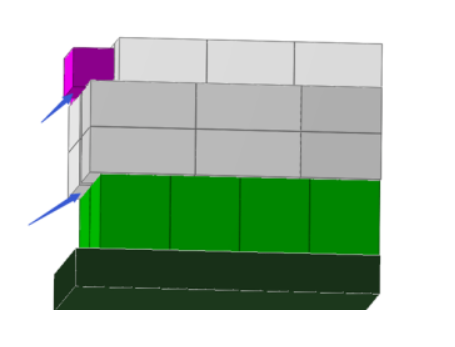

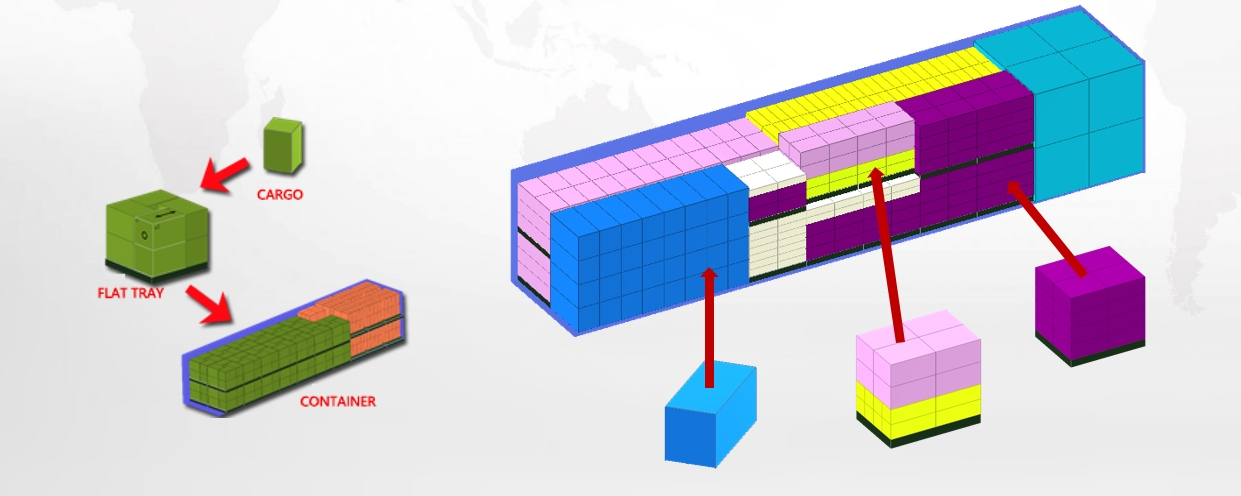

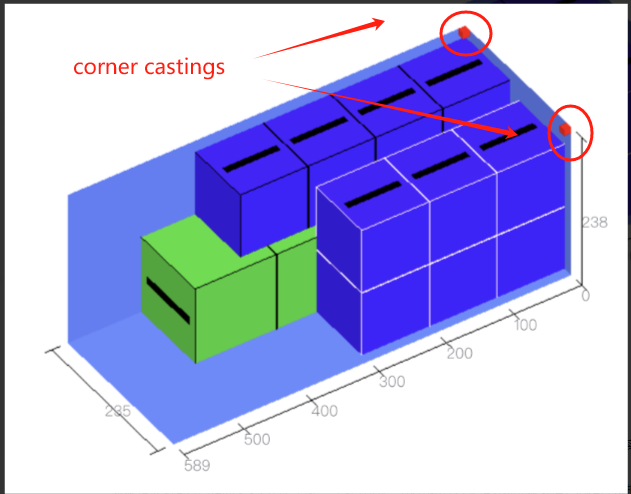

· 𝗗𝗲𝗳𝗶𝗻𝗲 𝗥𝗲𝗾𝘂𝗶𝗿𝗲𝗺𝗲𝗻𝘁𝘀: Before selecting load planning software, companies need to clarify specific requirements for cargo loading, stacking, and other aspects. Only by clearly understanding the dimensions and loading methods of goods can a foundation be laid for selecting suitable software.

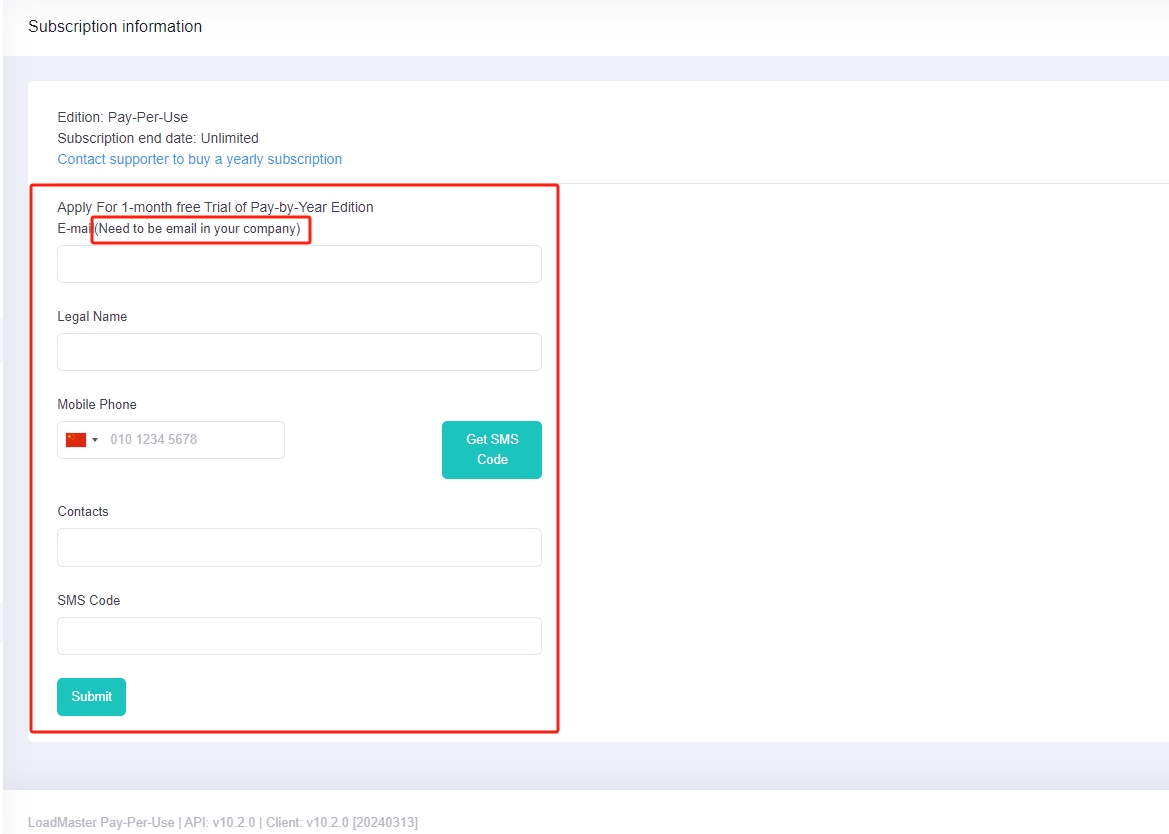

· 𝗦𝗽𝗲𝗰𝗶𝗳𝘆 𝗦𝗼𝗳𝘁𝘄𝗮𝗿𝗲 𝗩𝗲𝗿𝘀𝗶𝗼𝗻𝘀 𝗮𝗻𝗱 𝗙𝗲𝗮𝘁𝘂𝗿𝗲𝘀: After clarifying requirements, it is necessary to determine the version of the software and whether the functionalities under that version can meet actual needs. Even for the same software, different versions have different features, catering to the diverse needs of different enterprises. Therefore, companies need to make precise choices based on their own situations. If incorrect selection occurs due to various factors, it will not only result in financial and time losses but also undoubtedly create hurdles for the long-term development of the enterprise.

𝗟𝗼𝗮𝗱𝗠𝗮𝘀𝘁𝗲𝗿 𝗹𝗼𝗮𝗱 𝗽𝗹𝗮𝗻𝗻𝗶𝗻𝗴 𝘀𝗼𝗳𝘁𝘄𝗮𝗿𝗲 provides free and professional requirement clarification services for each enterprise during the trial period, assisting companies in clarifying requirements and laying a solid foundation for accurately calculating packing solutions. One of their previous clients, due to insufficient attention during requirement communication and confirmation, believed that they didn’t have certain requirements. As a result, they chose a cheaper and simpler version. However, during actual use, they found that some of their practical needs could only be met by a more advanced version, leading to unnecessary trouble for the entire process. Therefore, requirement clarification and specification are undoubtedly the cornerstone before selecting software.

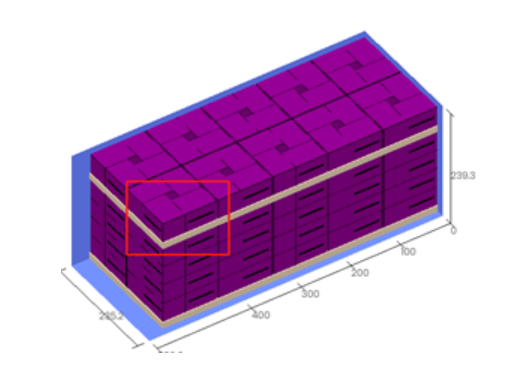

· 𝗧𝗲𝘀𝘁 𝘄𝗶𝘁𝗵 𝗔𝗰𝘁𝘂𝗮𝗹 𝗦𝗵𝗶𝗽𝗽𝗶𝗻𝗴 𝗗𝗮𝘁𝗮: After determining the software and version, companies should utilize accurate actual shipping data for testing. Comparing the packing and loading solutions provided by the software with their previous loading levels can validate:

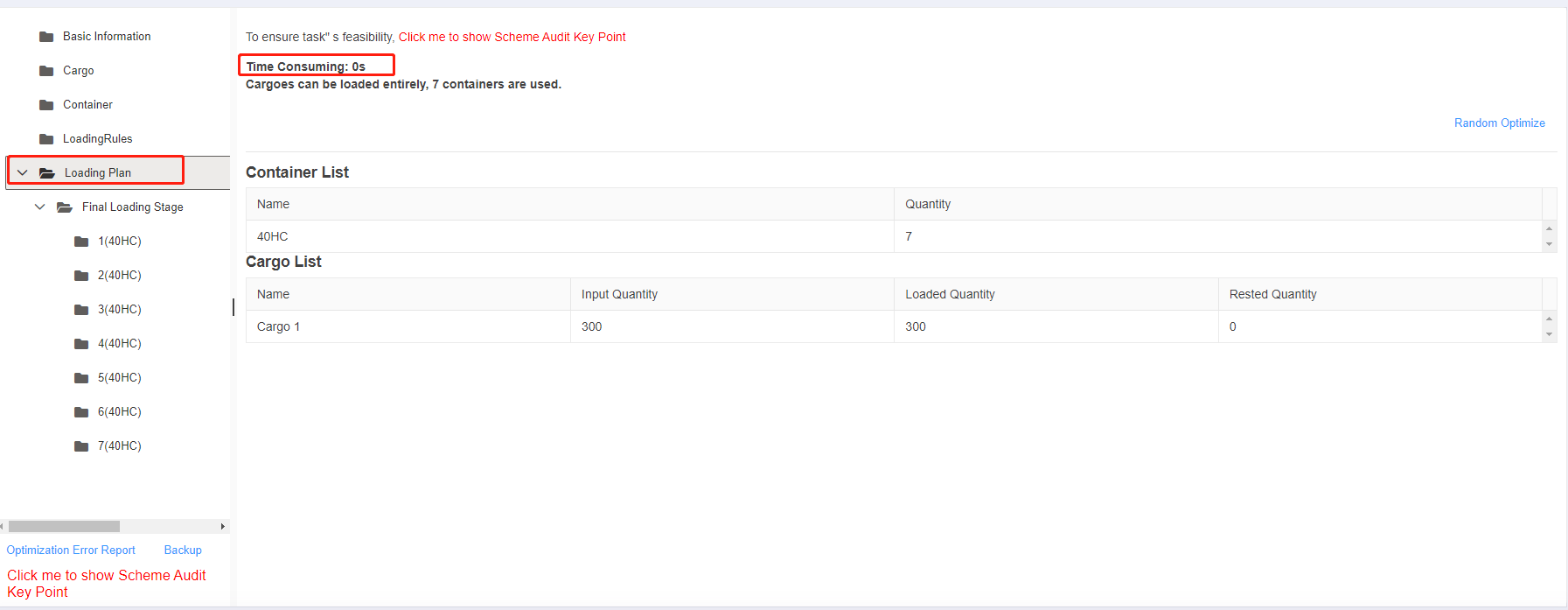

1.𝗖𝗮𝗻 𝘁𝗵𝗲 𝘀𝗼𝗳𝘁𝘄𝗮𝗿𝗲 𝗺𝗲𝗲𝘁 𝘁𝗵𝗲 𝗿𝗲𝗾𝘂𝗶𝗿𝗲𝗺𝗲𝗻𝘁𝘀? 𝗗𝗼 𝘁𝗵𝗲 𝗮𝗹𝗴𝗼𝗿𝗶𝘁𝗵𝗺𝘀 𝗯𝗲𝗵𝗶𝗻𝗱 𝘁𝗵𝗲 𝗳𝘂𝗻𝗰𝘁𝗶𝗼𝗻𝘀 𝗼𝗻 𝘁𝗵𝗲 𝘀𝗼𝗳𝘁𝘄𝗮𝗿𝗲 𝗶𝗻𝘁𝗲𝗿𝗳𝗮𝗰𝗲 𝗰𝗼𝗿𝗿𝗲𝘀𝗽𝗼𝗻𝗱 𝘁𝗼 𝗽𝗿𝗮𝗰𝘁𝗶𝗰𝗮𝗹 𝗶𝗺𝗽𝗹𝗲𝗺𝗲𝗻𝘁𝗮𝘁𝗶𝗼𝗻? Many clients of LoadMaster load planning software have reported that when testing other similar software, they found that although the interfaces were feature-rich, many functions were superficial, and the software algorithms simply could not correspond to practical functions, undoubtedly being “embroidered pillows”. Therefore, only by using real data for testing can such risks be minimized to the greatest extent.

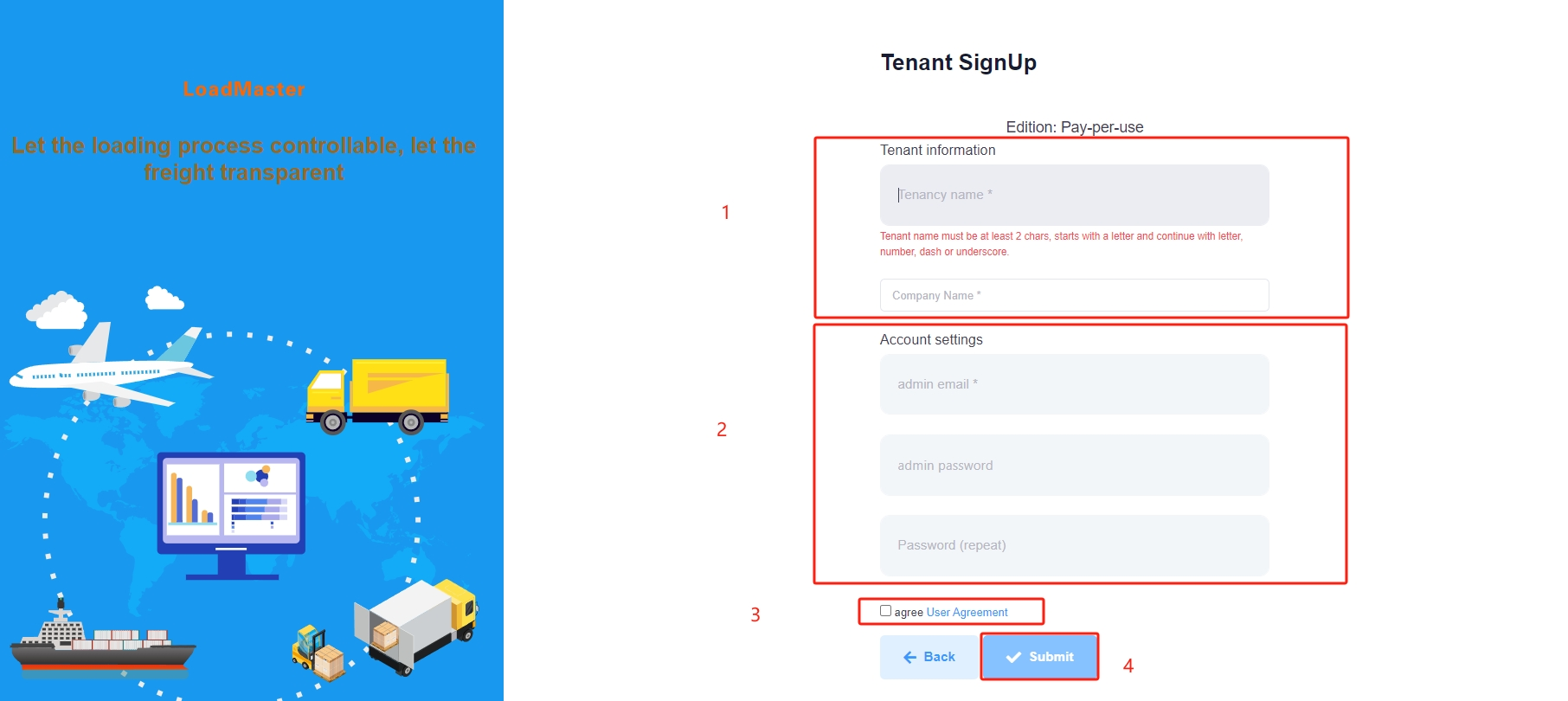

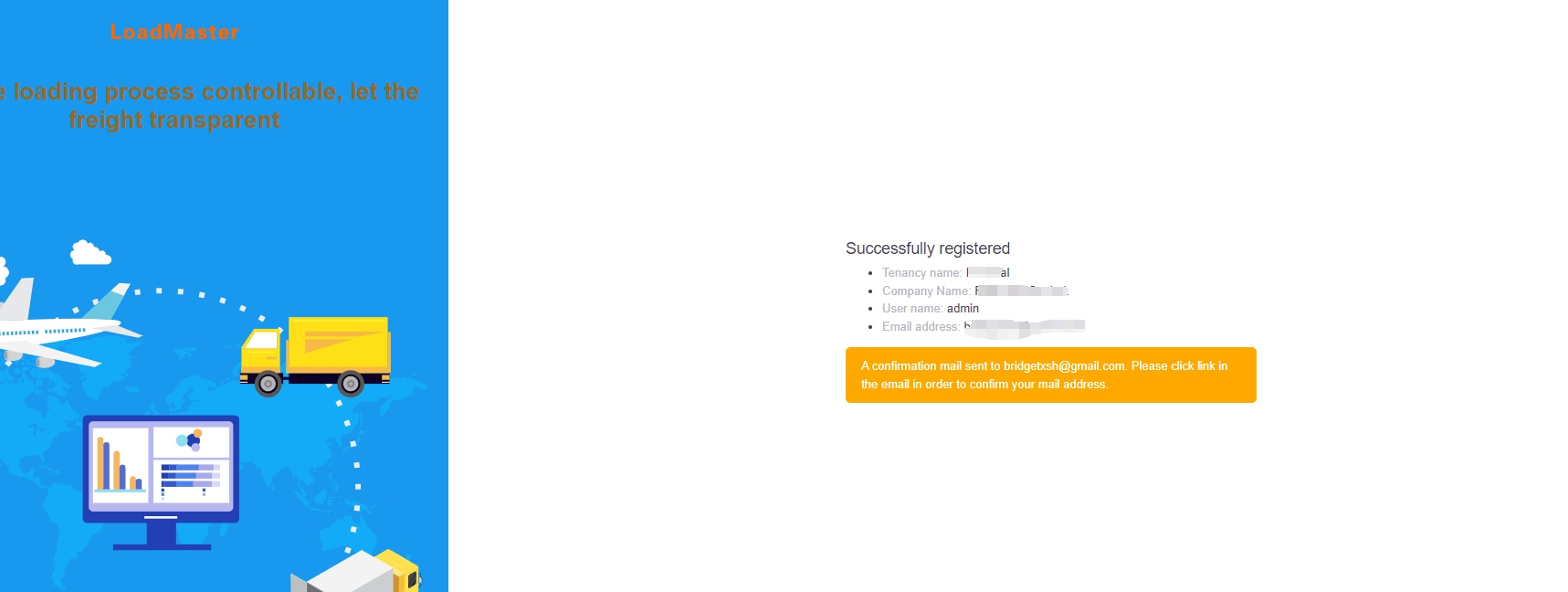

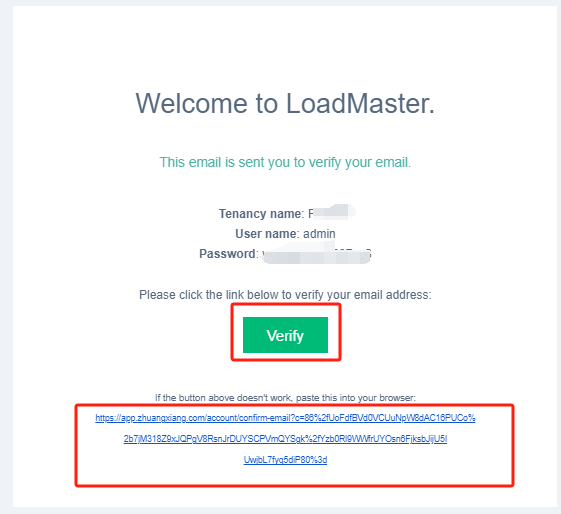

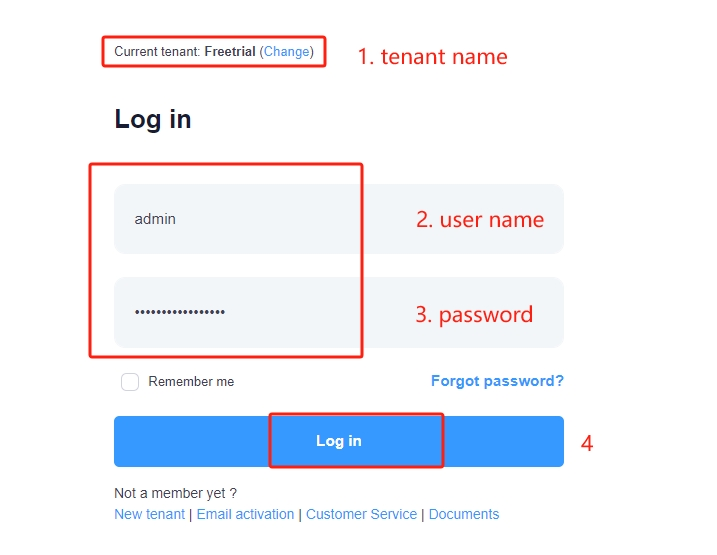

- After meeting the requirements, assess whether the software can reach the previous packing level? One of LoadMaster’s clients found during comparative evaluations of multiple load planning software that some software couldn’t even reach their existing manual level. In that case, what’s the value of purchasing the software? LoadMaster load planning software provides a 30-day full-function free trial for each enterprise, and during the trial period, free requirement clarification and remote demonstration of software operation services are provided, wholeheartedly assisting enterprises in trying out, experiencing, and comprehensively evaluating the software, ultimately selecting the most suitable one.

2.If the current packing level can be reached, are there improvements in loading rate, work efficiency, etc., and how much can be saved in terms of costs? Only after comprehensively evaluating these indicators can the input-output ratio of purchasing software and the ultimate empowerment for enterprises be understood.

Since its establishment in 𝟮𝟬𝟬𝟳, LoadMaster load planning software has served more than 500 globally renowned customers and over 3,000 large and medium-sized enterprises, covering 𝟴𝟬% of China’s home appliance and auto parts industry enterprises. According to feedback from these clients, after using LoadMaster, the loading rate can be increased by 𝟭𝟬% on average, and load plan calculation time can be reduced by 𝟵𝟬%. One client, a manager from TPV Technology, reported that introducing LoadMaster could save them tens of millions of transportation costs annually, astonishing the board of directors. This case once again confirms the importance of clarifying requirements for selection and demonstrates the immense value that correctly choosing load planning software brings to the long-term development of enterprises.

𝗖𝗼𝗻𝗰𝗹𝘂𝘀𝗶𝗼𝗻

In the future world, going with the flow is the key to success. Choosing the right high-quality load planning software can help companies quickly achieve logistics intelligence and supply chain intelligence, improve transportation efficiency, reduce costs, and enhance market competitiveness. Therefore, avoiding wrong choices is of great significance to enterprises. Only by striving forward in the right direction can success be infinitely close. Otherwise, it will only lead to wasted time and money, going in the opposite direction. LoadMaster will spare no effort to assist you in making the right choice, maximizing the role of load planning software in logistics optimization, and empowering logistics intelligence and supply chain intelligence limitlessly!

(

(