Panasonic is a Japanese transnational corporation, one of the world’s largest electronics manufacturers, with hundreds of branches and offices distributed in dozens of countries and regions in Asia, Europe, America, Oceania. Panasonic China is a branch of Panasonic in China with its business covering consumer electronics, home appliances, general and industrial appliances, electronic components, communication systems and various equipment, system engineering and other fields. Panasonic China is one of the leading consumer electronics brands in the Chinese market. So why did we choose the cargo loading plan software LoadMaster among its other competitors? Let’s figure it out.

Panasonic China has a wide range of products with varying sizes and large shipping quantities, making manual container loading calculation time-consuming and laborious. Furthermore, palletizing cargoes is necessary before loading them into containers, complicating the process further. Human labor is unable to calculate an accurate and efficient load plan, resulting in wasted space and higher shipping costs. Therefore, there is a necessity to increase the container utilization rate to decrease freight costs. After comparing with other similar softwares, the cargo loading plan software LoadMaster stood out.

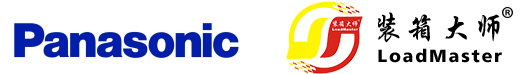

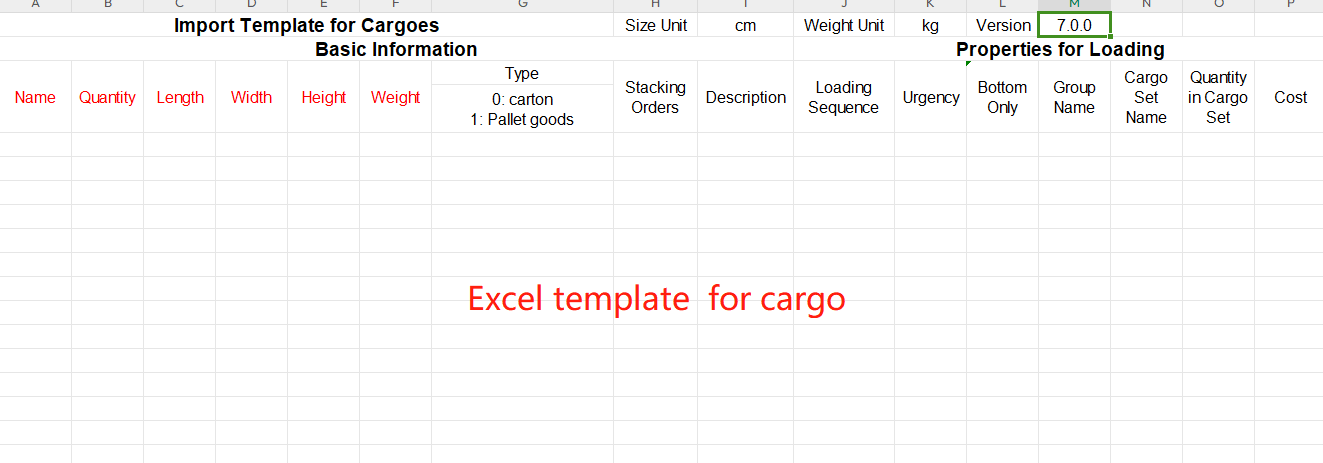

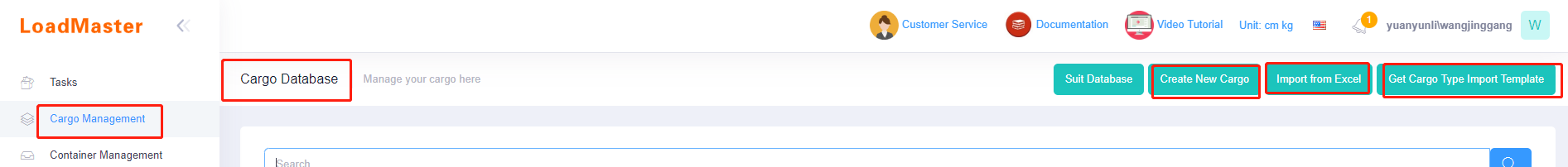

With the help of LoadMaster cargo loading plan software, loads of cargo and container information can be imported to the load calculator in the way of cargo excel template. What’s more, the basic information and attributes of frequently shipped cargoes and containers can be saved into the cargo loading plan software’s database to avoid repeated input work when next time we need to transport the same cargoes and containers. It’s also very convenient to find a certain loading solution in task history.

LoadMaster cargo loading plan software can not only meet all our loading requirements but also help us to choose the most suitable pallet after we import the sizes of several pallets that we often use to the container loading software.

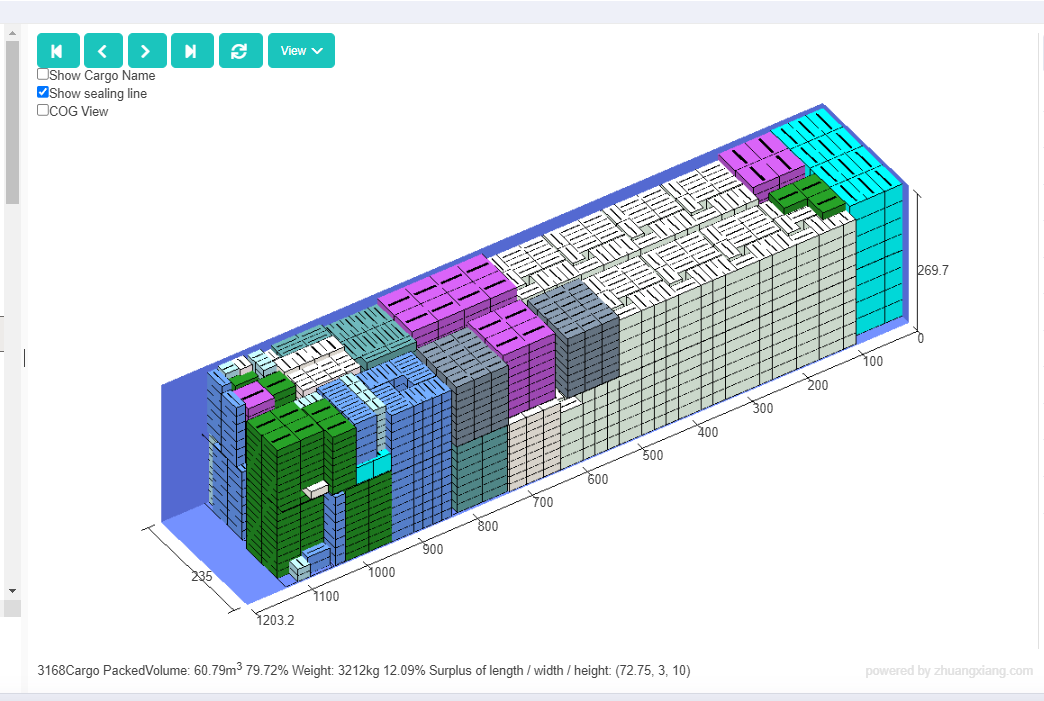

The 3D load plan diagram can show us clearly how the cargoes are loaded in containers. The load plan can be shared to mobile platforms to guide on-site loading.

As to the real benefits this cargo loading plan software has brought to us, the container utilization rate has been improved by 10% and the working efficiency has also been increased by 83%.

Check how we can help home appliances industry at https://blog.loadmaster.biz/2023/11/02/40/

TRANE logo and LoadMaster logo.

TRANE logo and LoadMaster logo. Complex calculation.

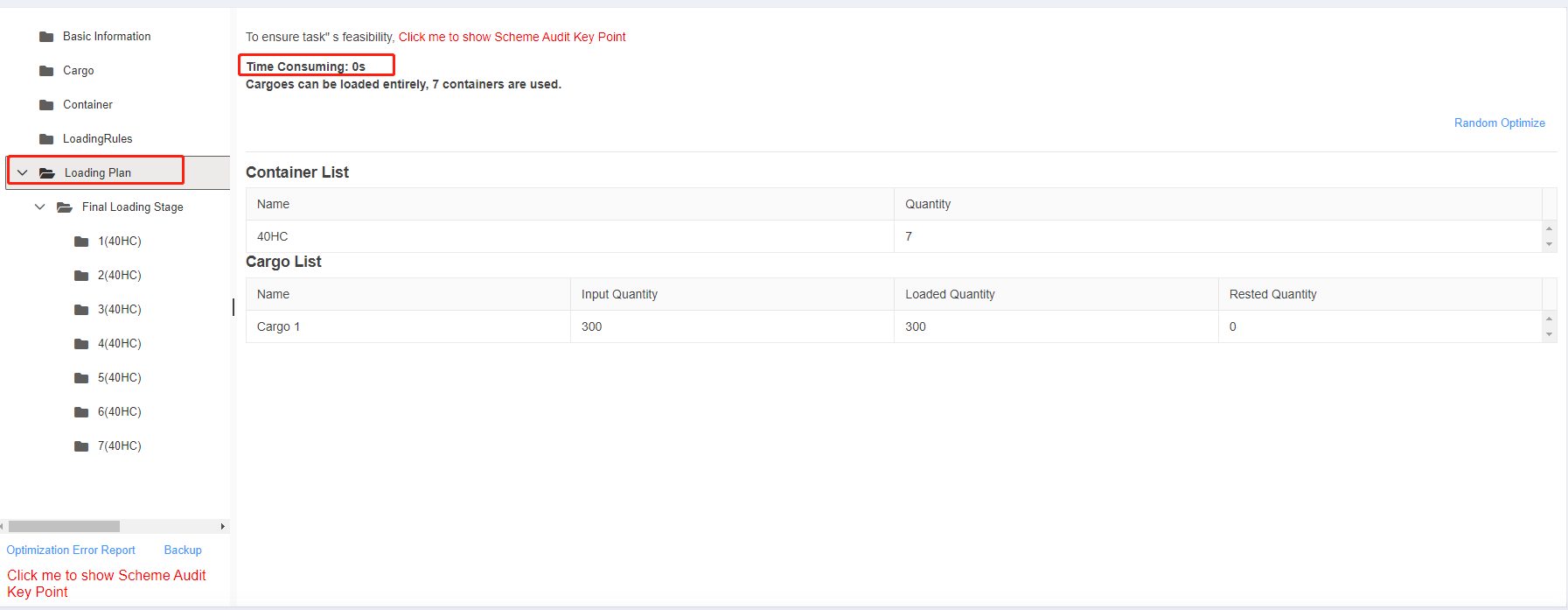

Complex calculation. Fast computing speed.

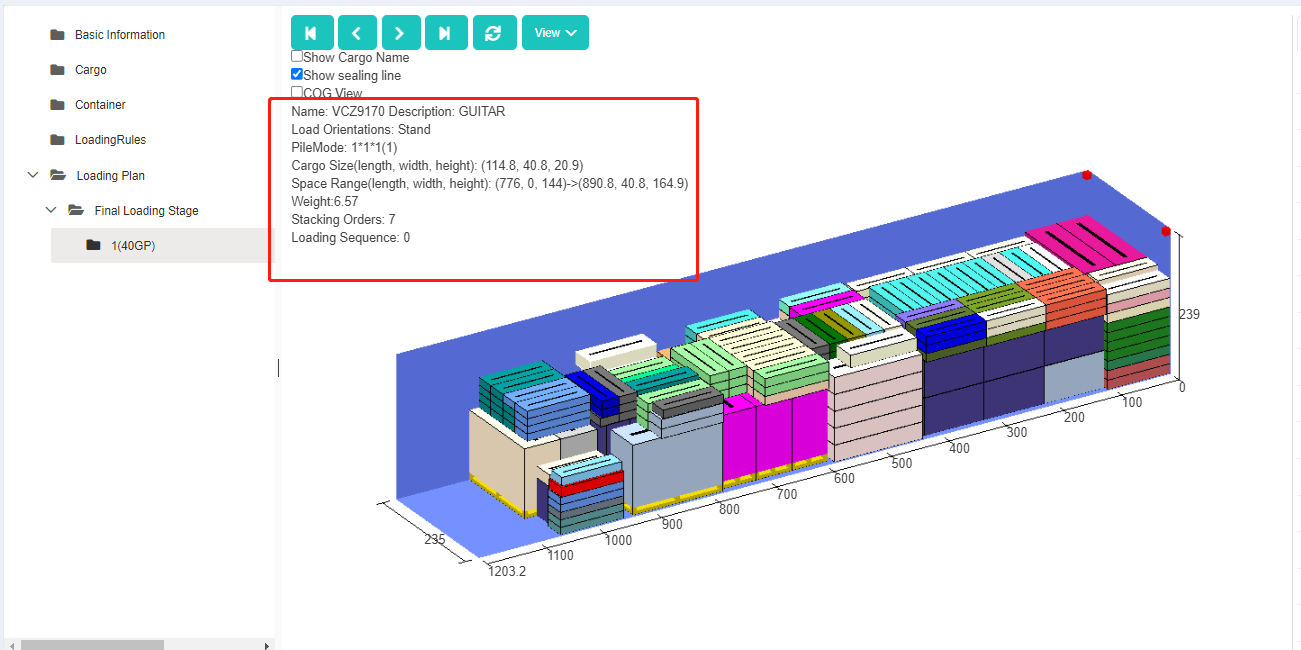

Fast computing speed. Detailed cargo information on 3d load plan.

Detailed cargo information on 3d load plan. A woman asking for help.

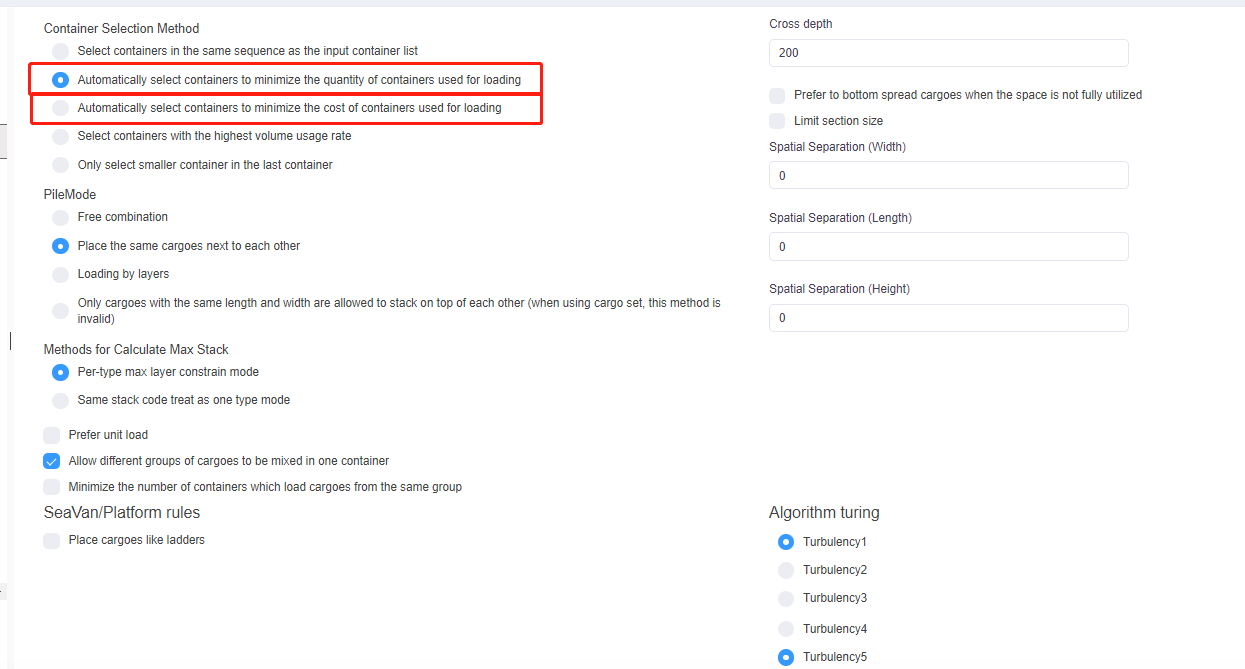

A woman asking for help. Container selection rule “Minimize costs”.

Container selection rule “Minimize costs”. Fast computing speed.

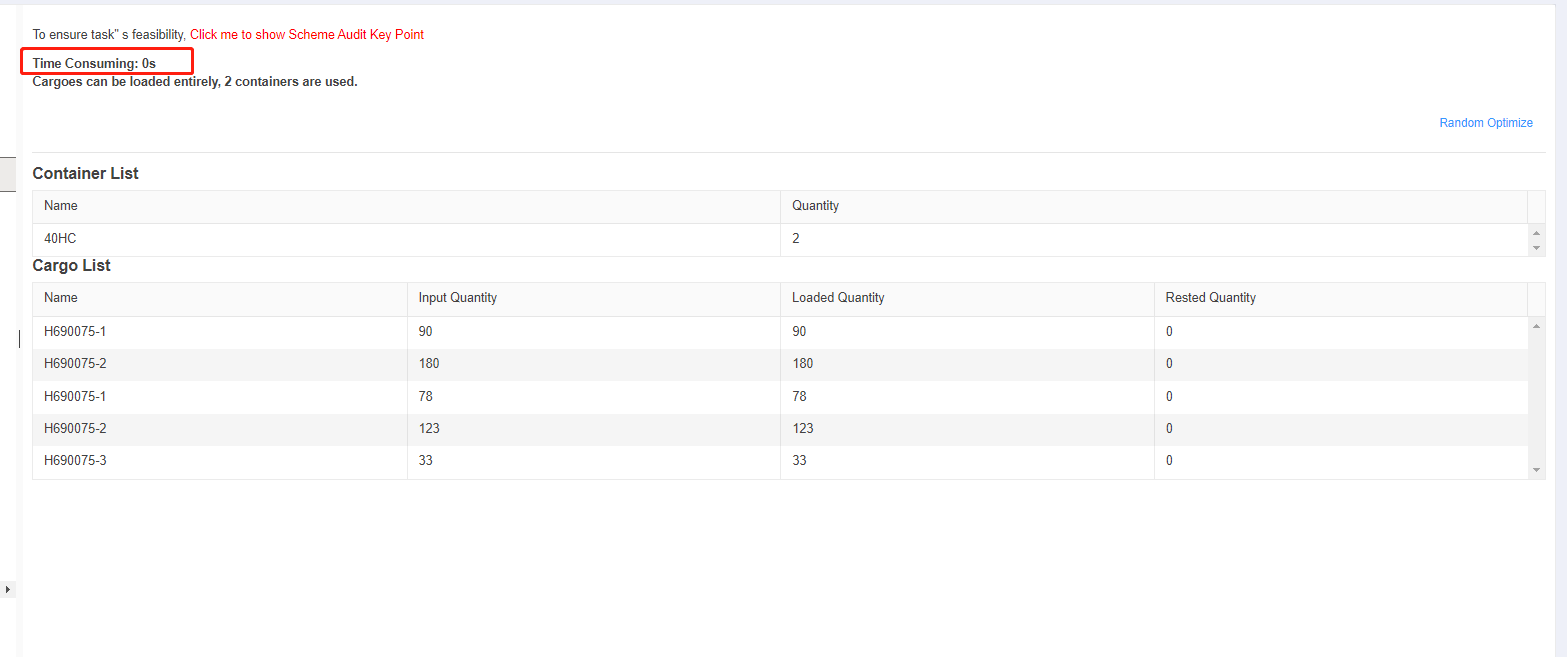

Fast computing speed. Costs decrease greatly.

Costs decrease greatly. Hisense website screenshot.

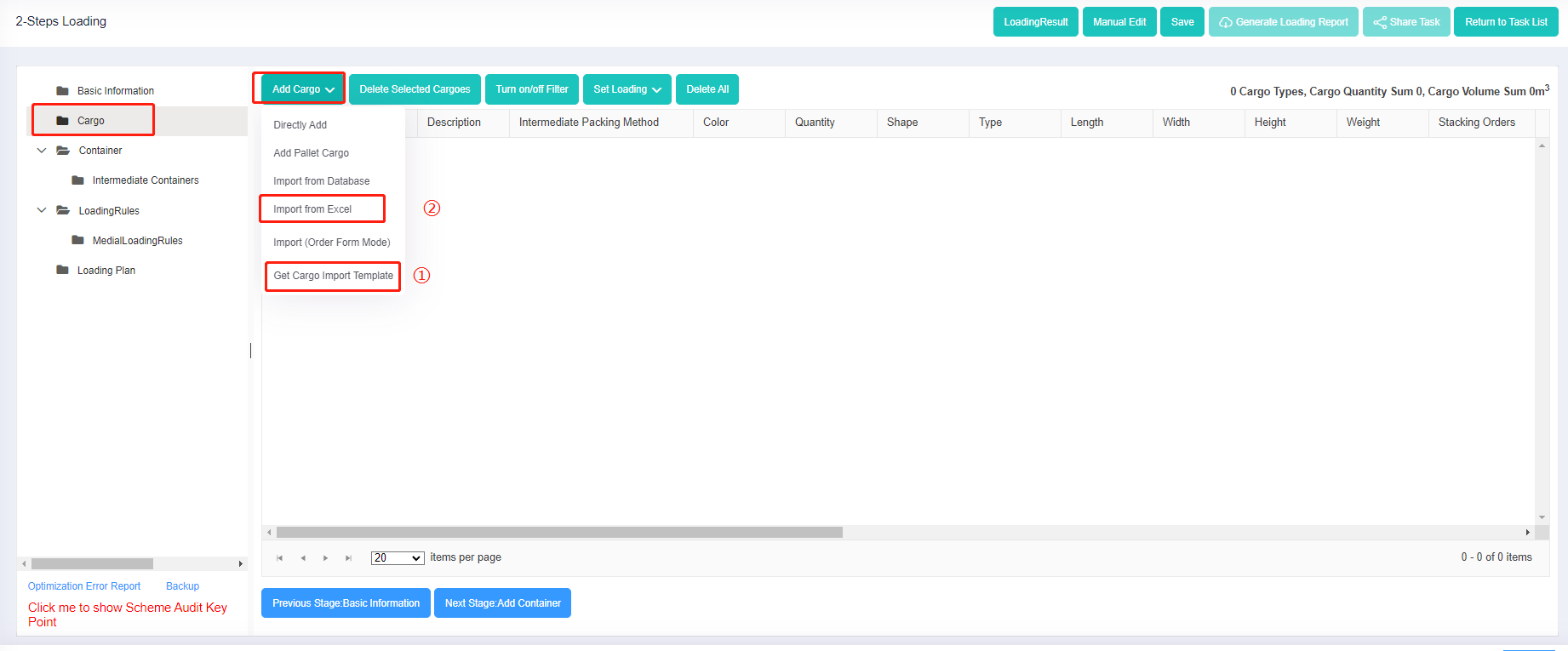

Hisense website screenshot. Add cargo through excel template.

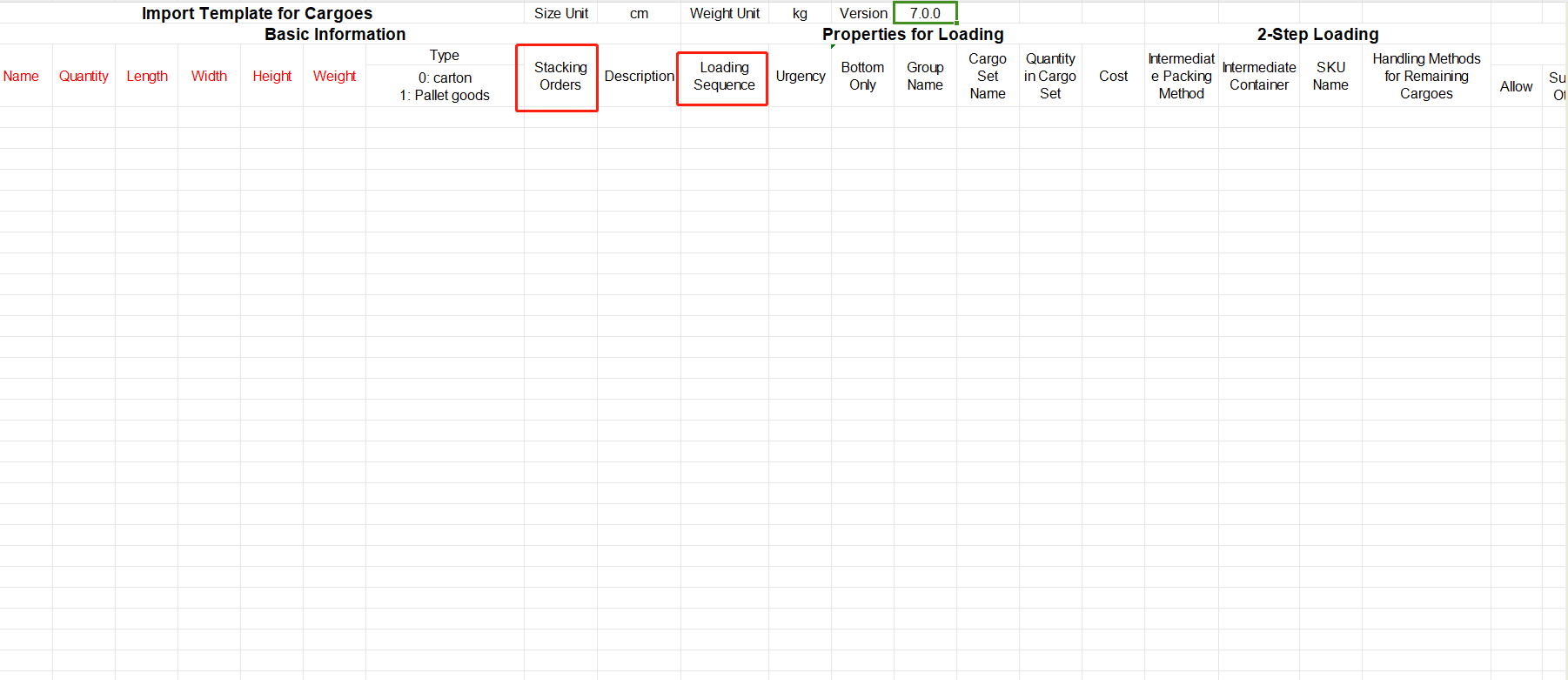

Add cargo through excel template. Parameters Stacking Orders and Loading Sequence.

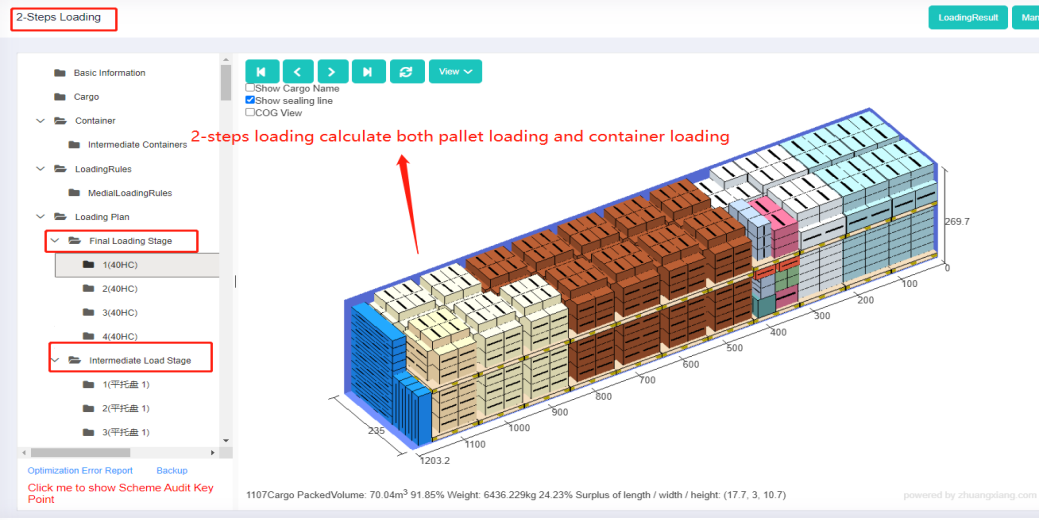

Parameters Stacking Orders and Loading Sequence. A 3d two-steps loading plan.

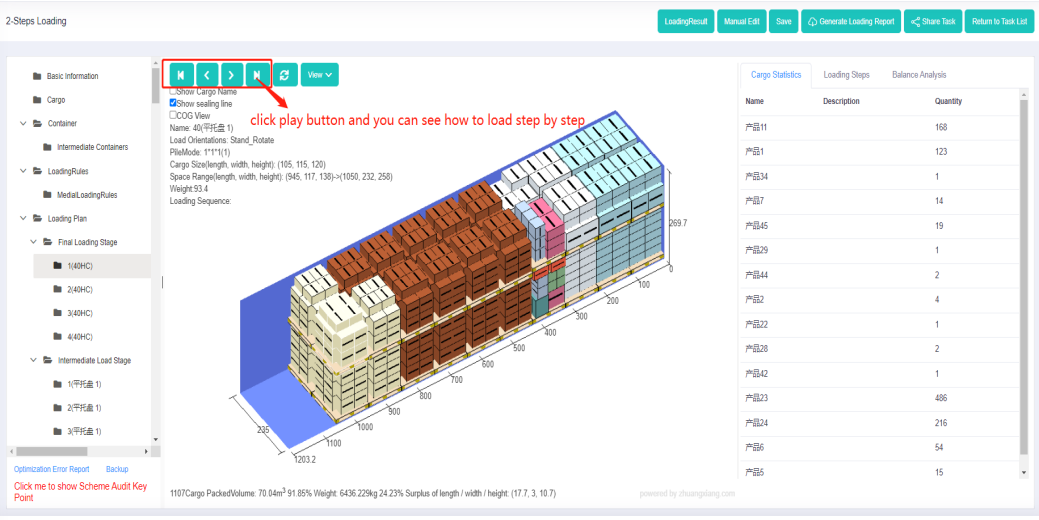

A 3d two-steps loading plan. Play buttons to click to display step-by-step loading.

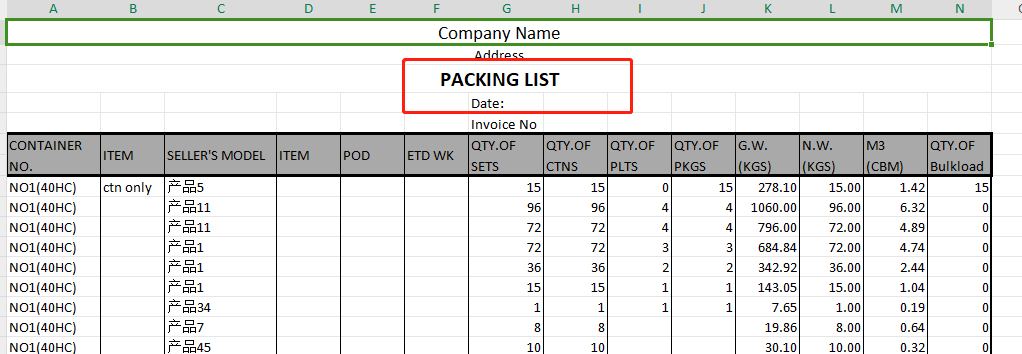

Play buttons to click to display step-by-step loading. Packing list report.

Packing list report. This is people loading cargoes into a container on site.

This is people loading cargoes into a container on site. Cargo waiting to be loaded into a container.

Cargo waiting to be loaded into a container. Cargo shipping scene.

Cargo shipping scene. Different kinds of furniture display.

Different kinds of furniture display. Loading staff loading cargo on site.

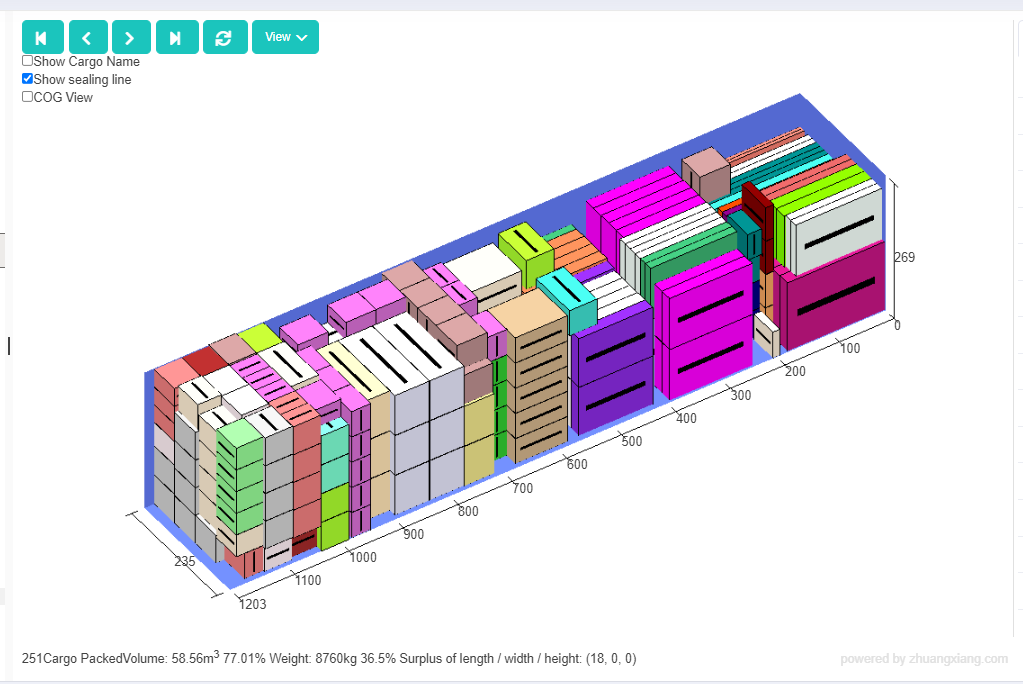

Loading staff loading cargo on site. 3d load plan display

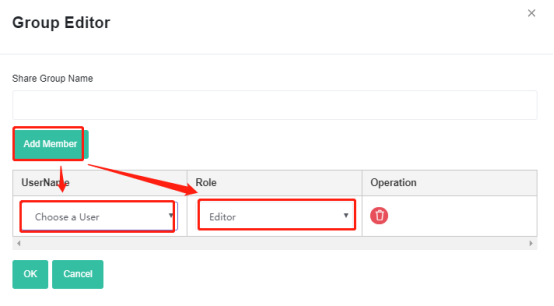

3d load plan display Add member and edit the role.

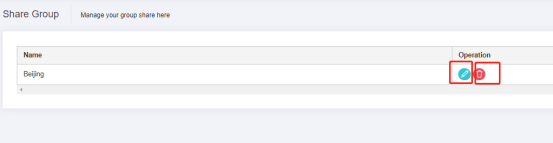

Add member and edit the role. Can modify and delete the created group.

Can modify and delete the created group. Approve sign.

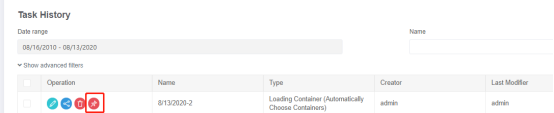

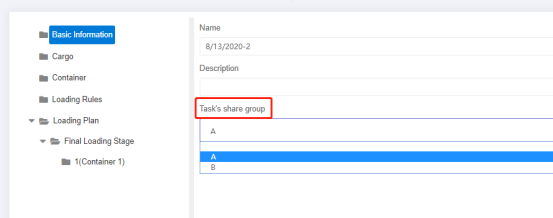

Approve sign. Can select share groups.

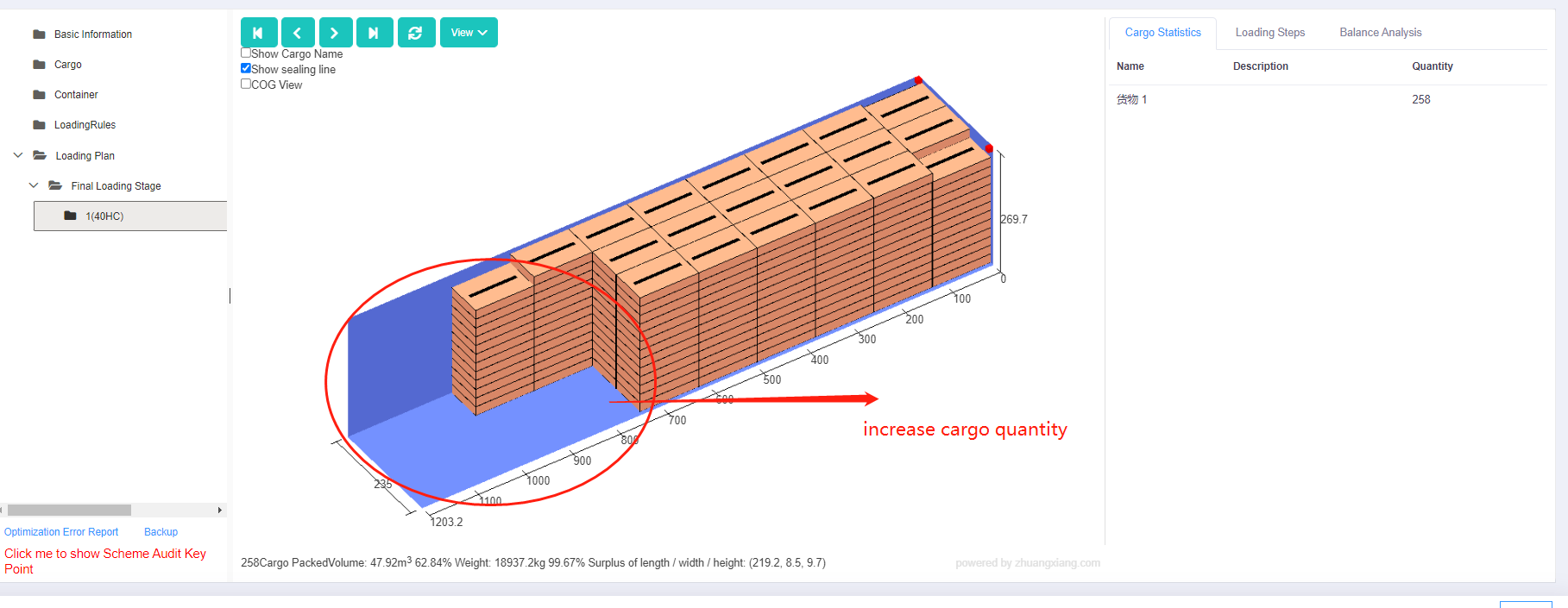

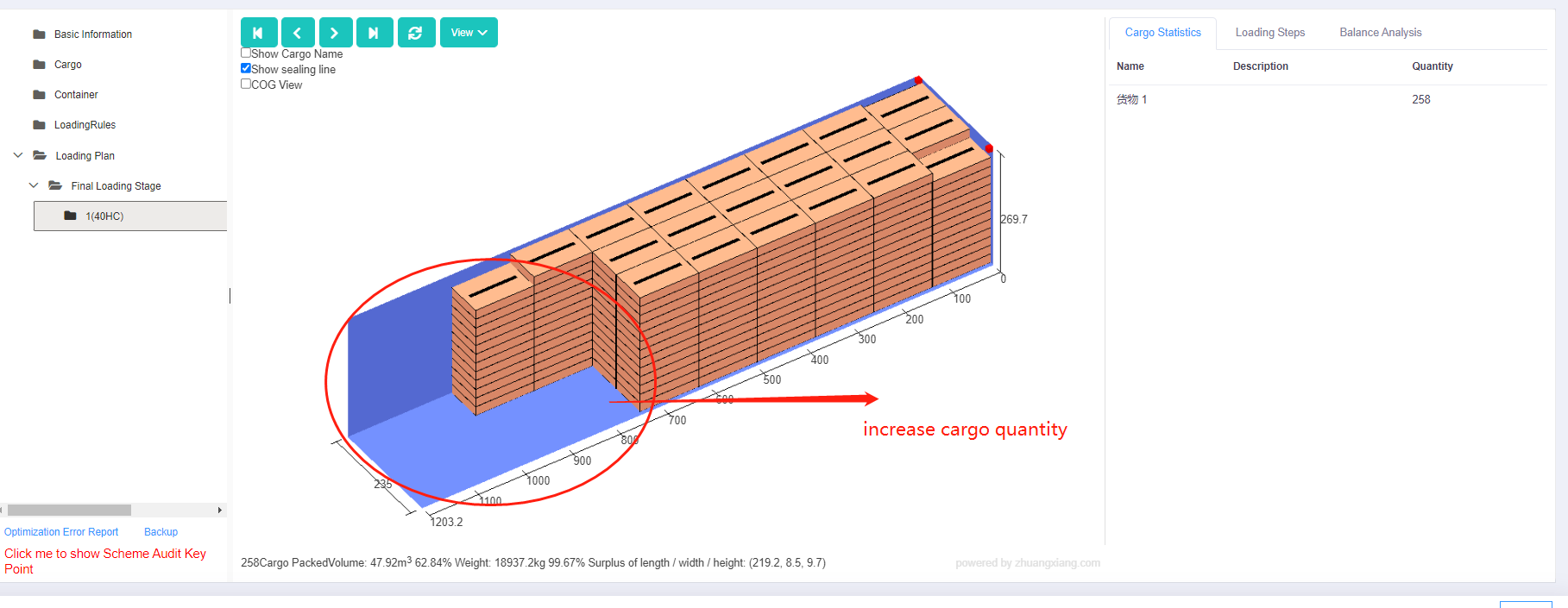

Can select share groups. More space to increase cargo quantity in a container.

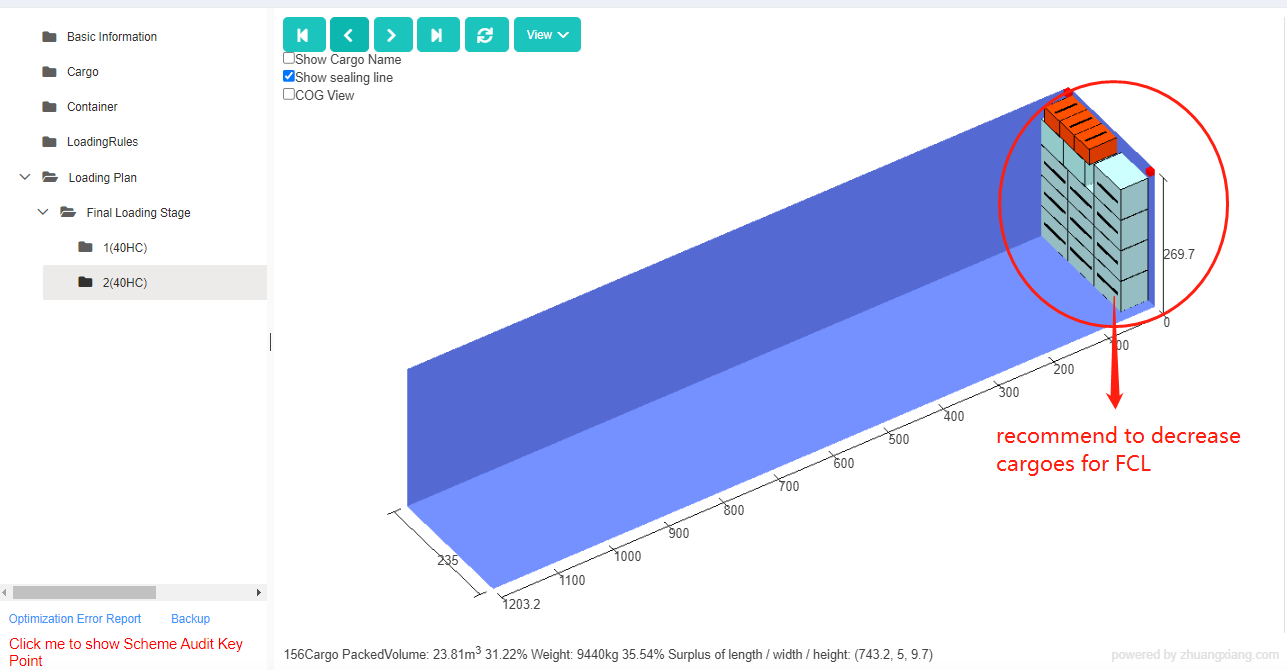

More space to increase cargo quantity in a container. Decrease cargo quantity.

Decrease cargo quantity. Hold hands to represent cooperation.

Hold hands to represent cooperation. Stagnant inventory.

Stagnant inventory. Palletized cargo waiting to be loaded into a container.

Palletized cargo waiting to be loaded into a container. A metal products factory.

A metal products factory. Stagnant inventory.

Stagnant inventory. Manual loading on site.

Manual loading on site. Space where more cargoes can be added in a container.

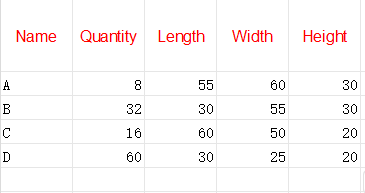

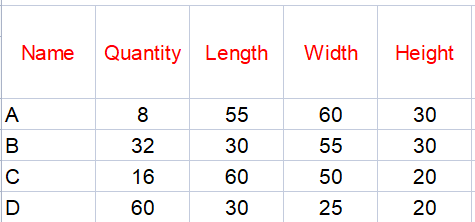

Space where more cargoes can be added in a container. Cargo dimensions.

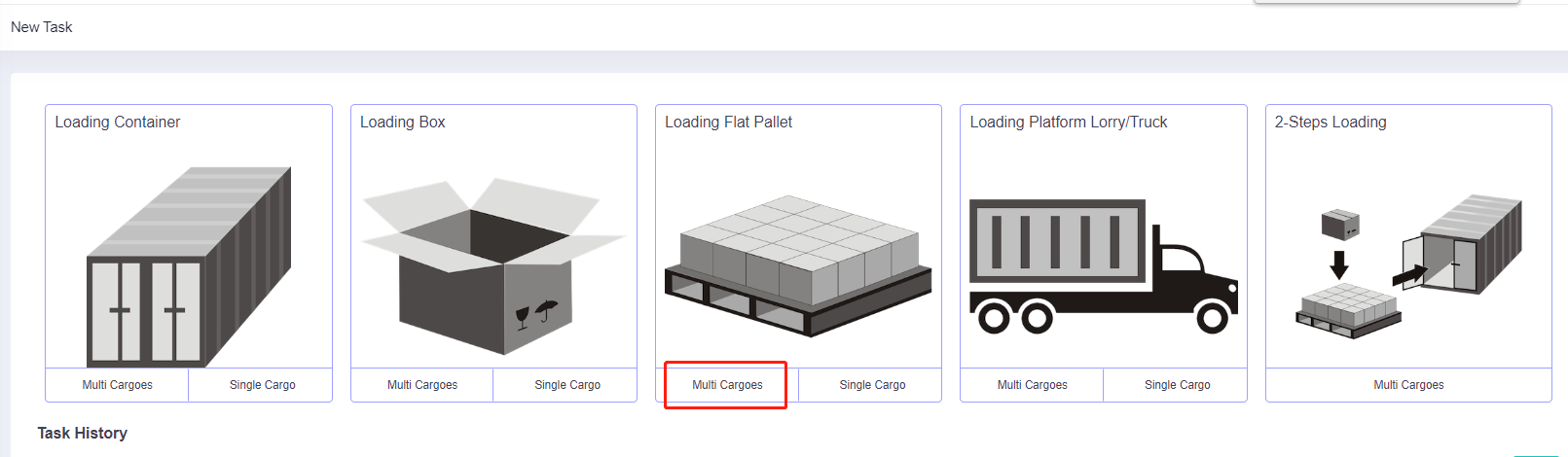

Cargo dimensions. Loading task type: multi cargo pallet loading.

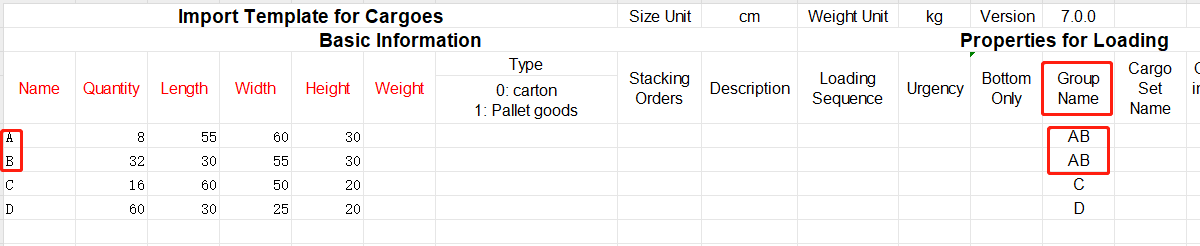

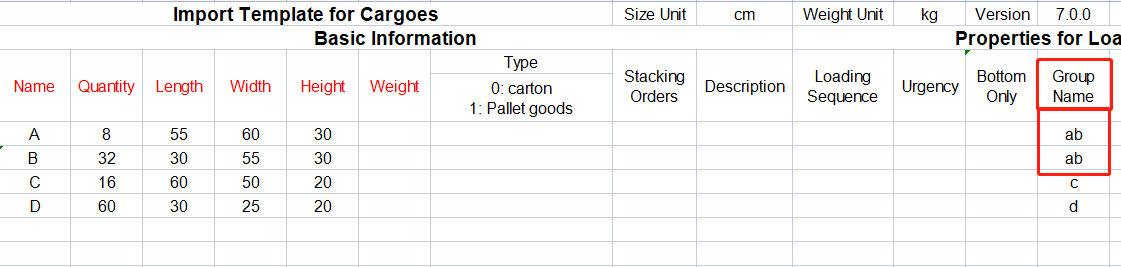

Loading task type: multi cargo pallet loading. Set group name in the template.

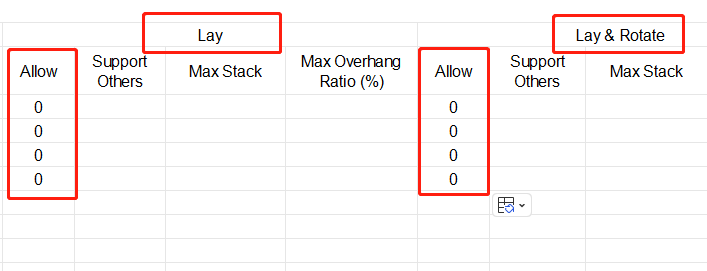

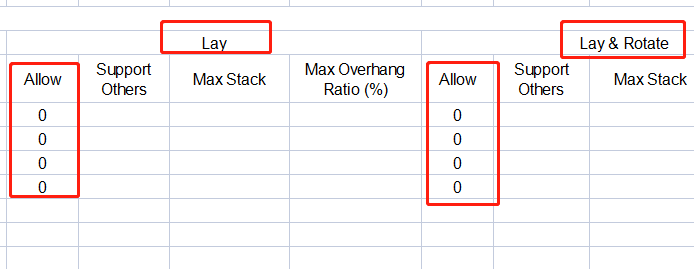

Set group name in the template. Disallow “Lay”, “Lay&Rotate”.

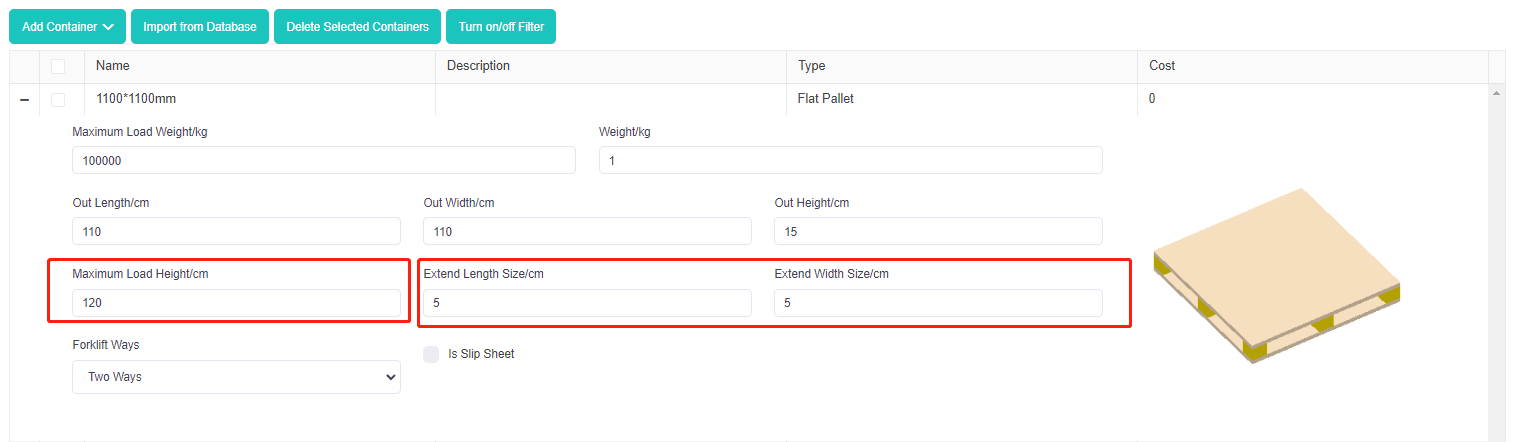

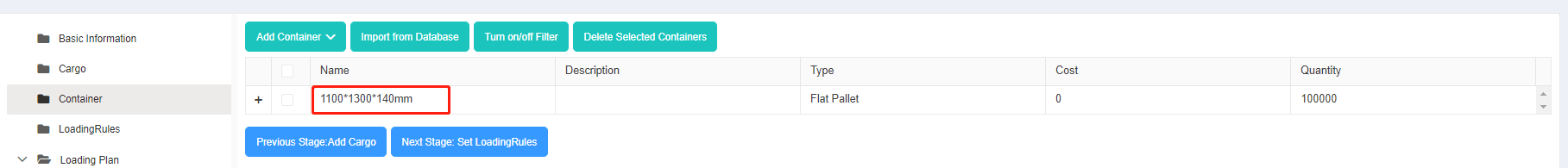

Disallow “Lay”, “Lay&Rotate”. Add the pallet.

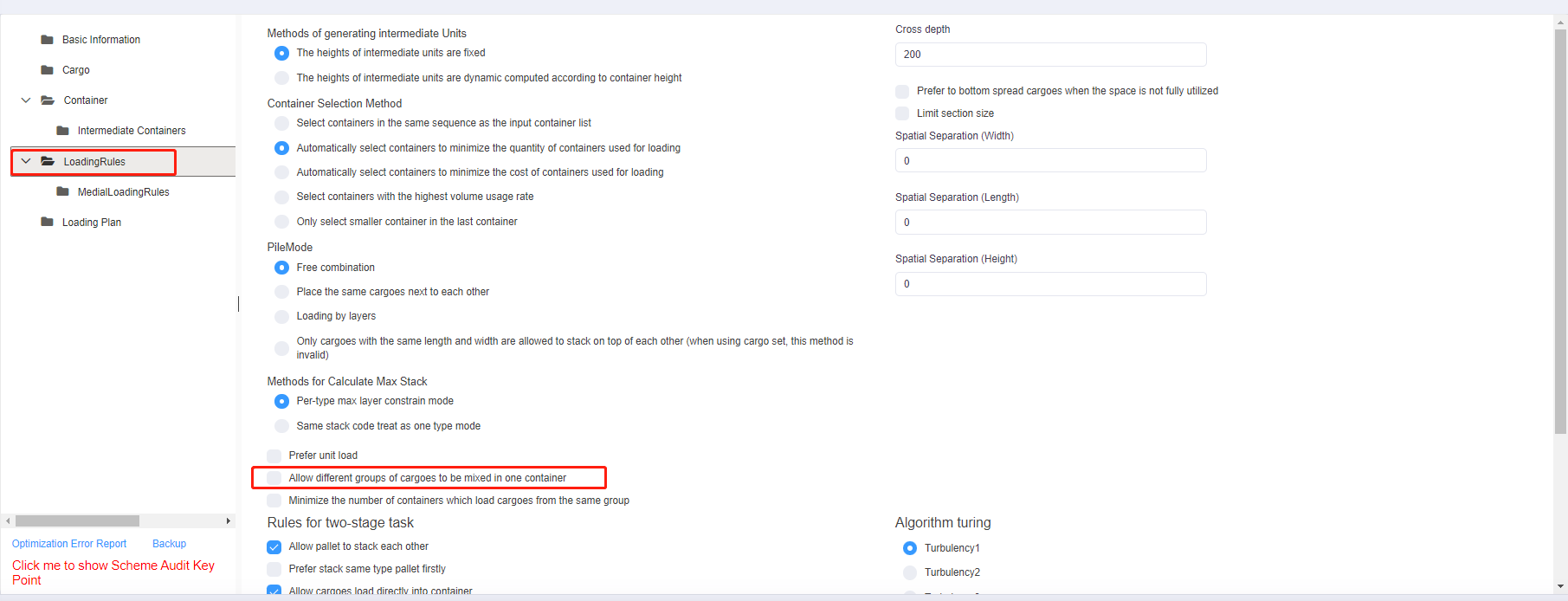

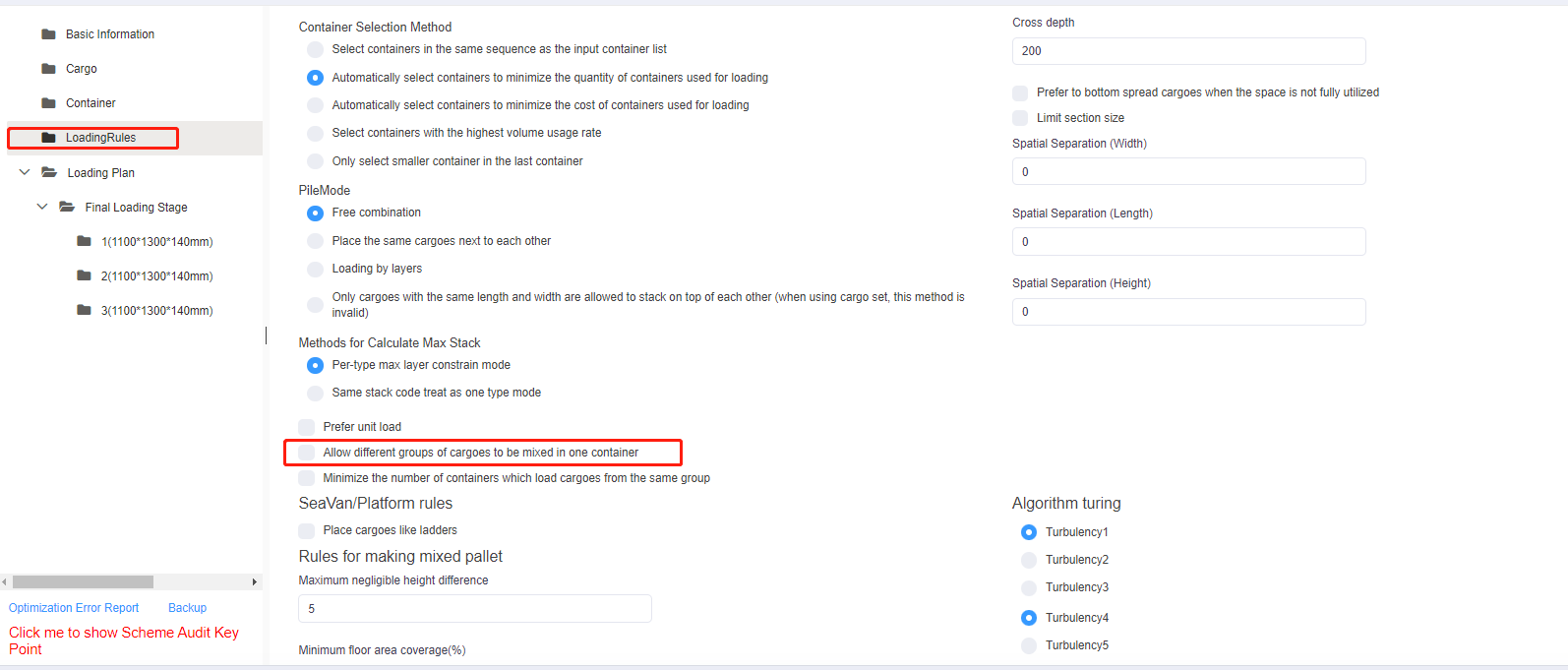

Add the pallet. Check the rule “Allow different groups of cargoes mixed in one container”.

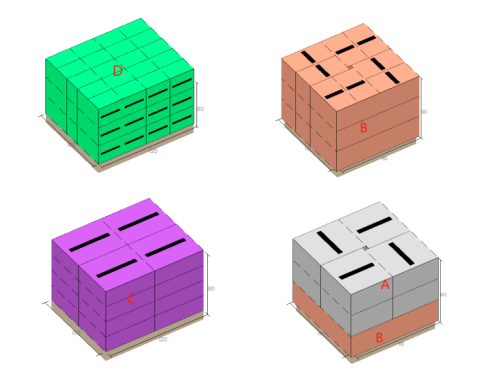

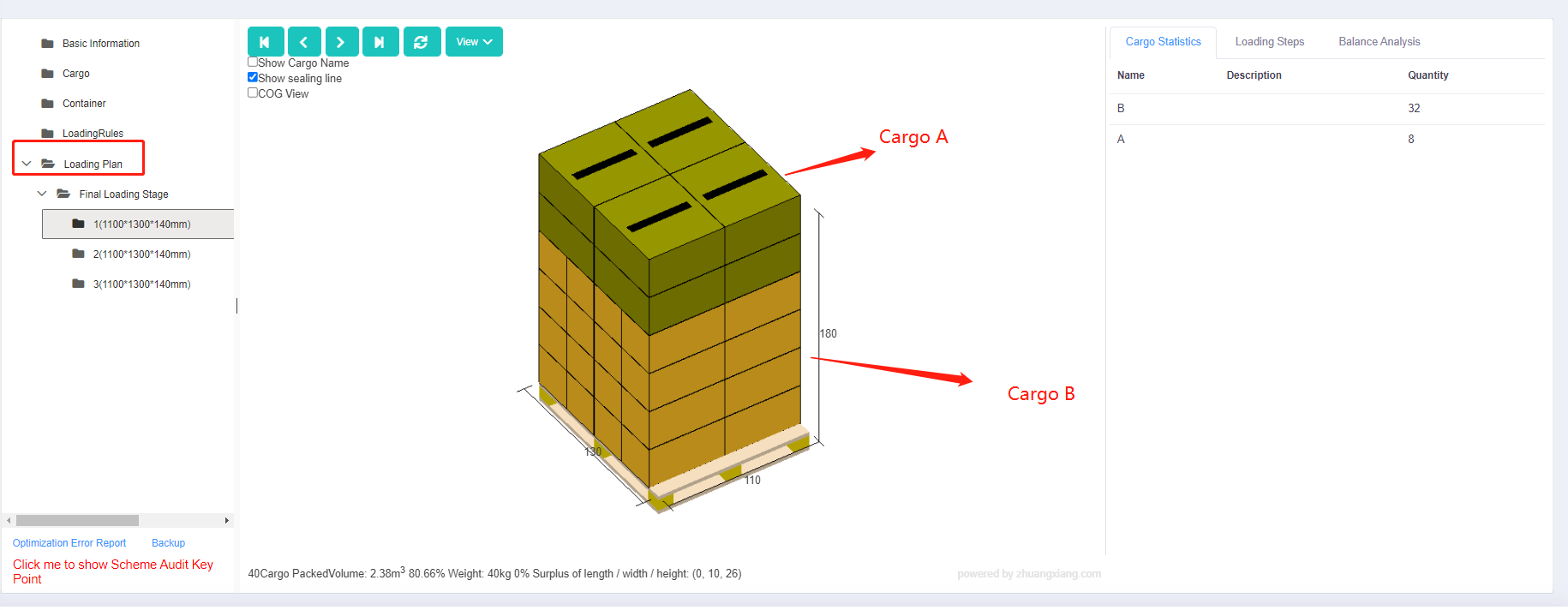

Check the rule “Allow different groups of cargoes mixed in one container”. Cargo A and Cargo B are mixed on one pallet.

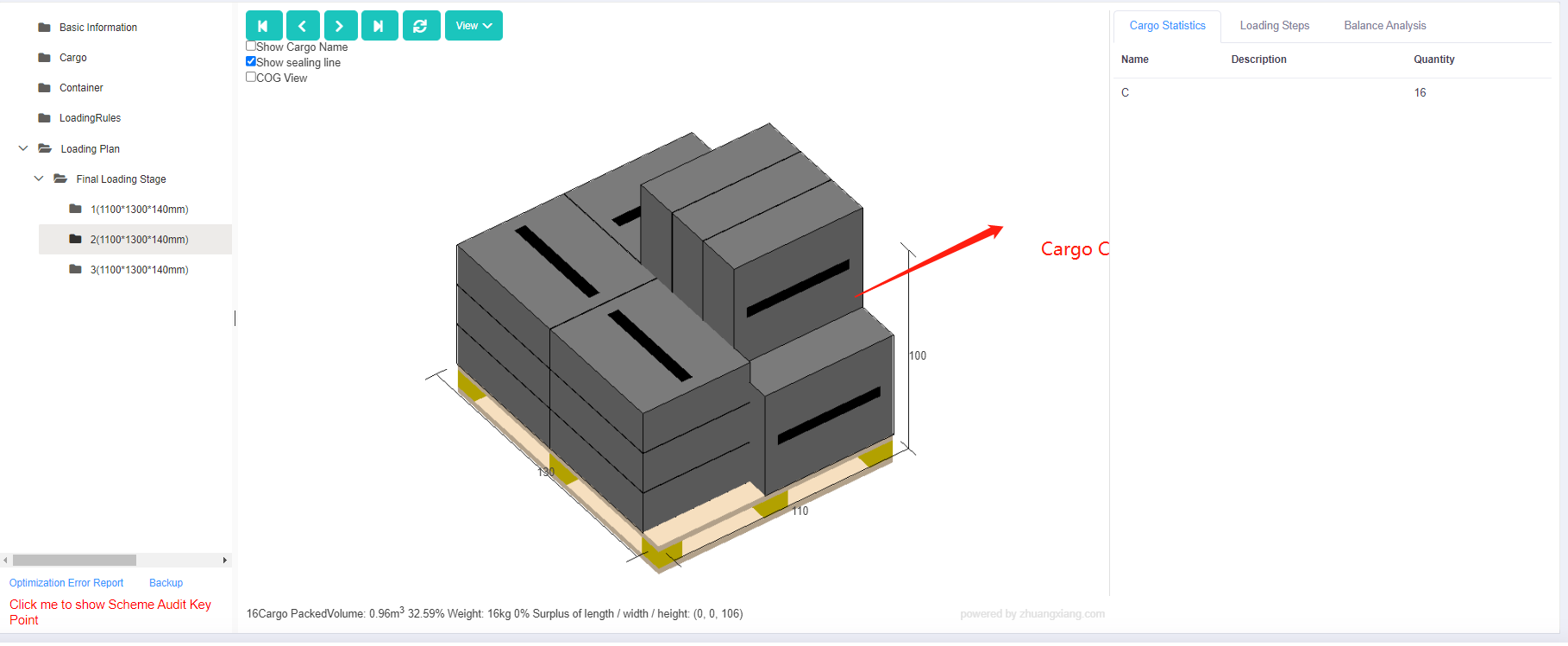

Cargo A and Cargo B are mixed on one pallet. Cargo C on the pallet.

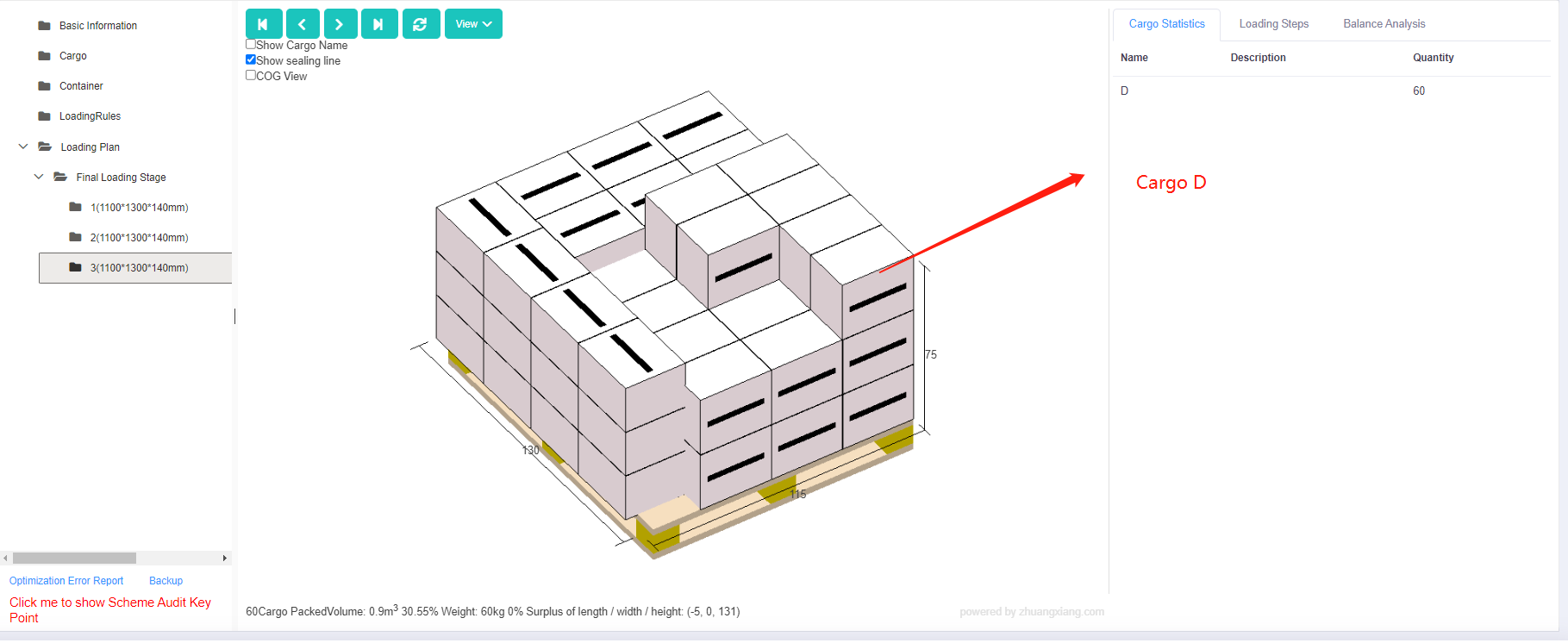

Cargo C on the pallet. Cargo D on the pallet.

Cargo D on the pallet.